Bearing condition monitor for a vehicle, such as a truck or a trailer

a technology for monitoring systems and vehicles, applied in electric vehicles, electric devices, vehicular safety arrangements, etc., can solve problems such as the loss of the entire wheel, including both rims and tires, and the possibility of catastrophic damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] While the invention may be susceptible to embodiment in different forms, there is shown in the drawings, and herein will be described in detail, a specific embodiment with the understanding that the present disclosure is to be considered an exemplification of the principles of the invention, and is not intended to limit the invention to that as illustrated and described herein.

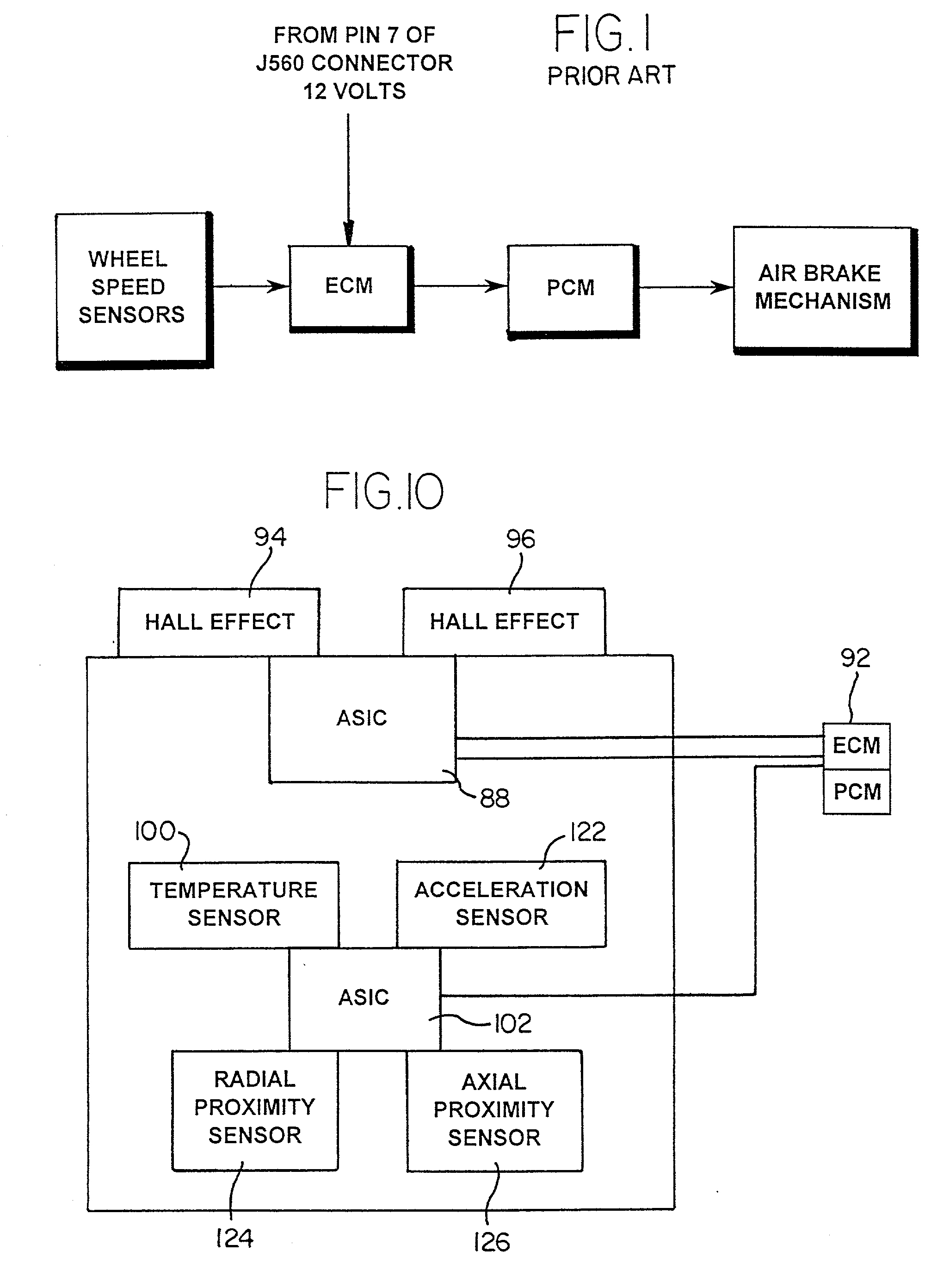

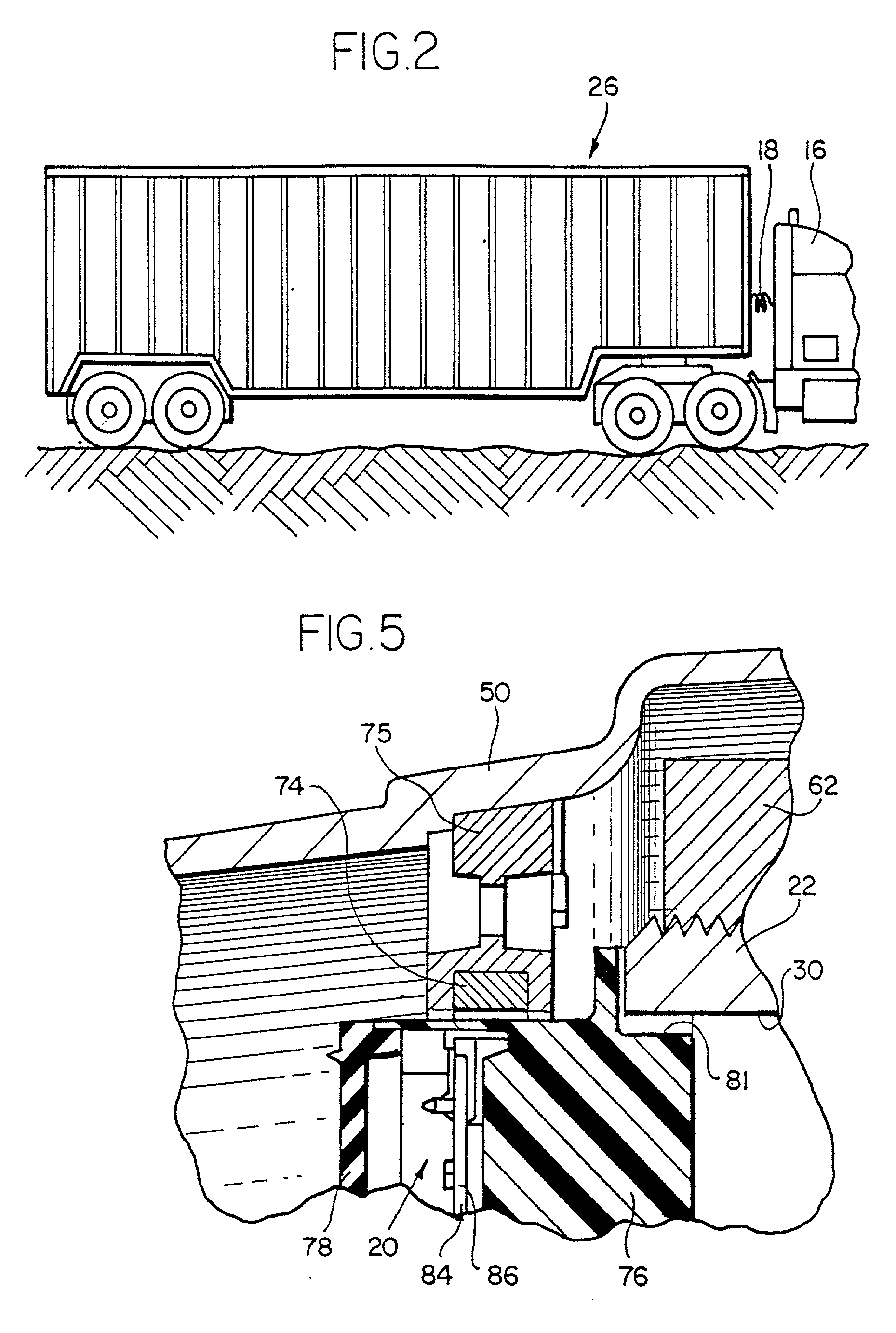

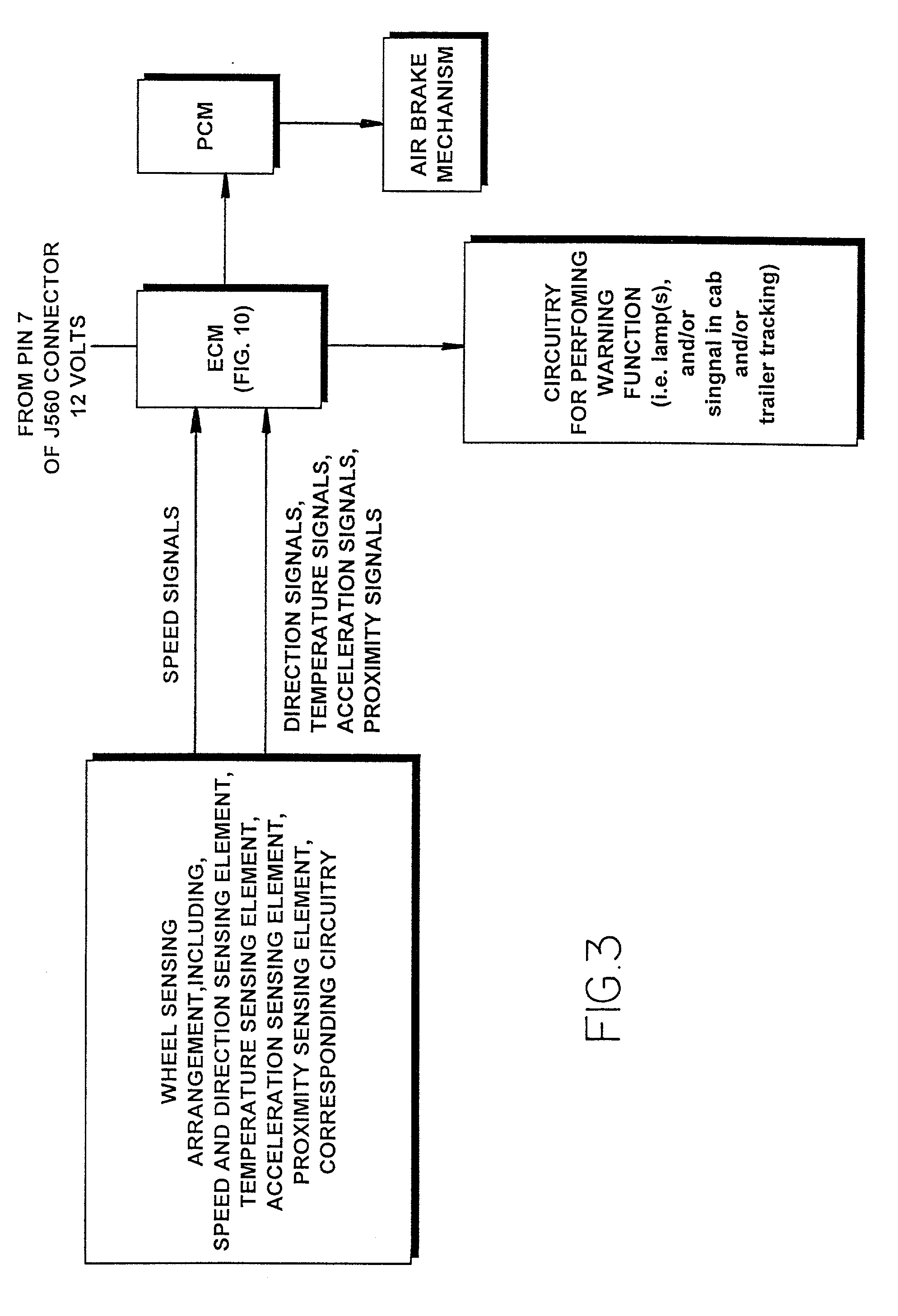

[0029] The present invention provides a bearing monitoring system for monitoring the health of a bearing 34, 36 of a wheel of a vehicle 26, such as a truck or a trailer. The bearing monitoring system is configured to monitor at least one characteristic related to the bearings 34, 36, such as a temperature generally proximate the bearings 34, 36, vibrations of one or more elements of the wheel mounting apparatus 24, and / or the proximity of a rotating element of the wheel. The monitoring system may be configured to monitor more than one of these characteristics (i.e., temperature, vibration and proximity)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com