Noise reduction system for kitchen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

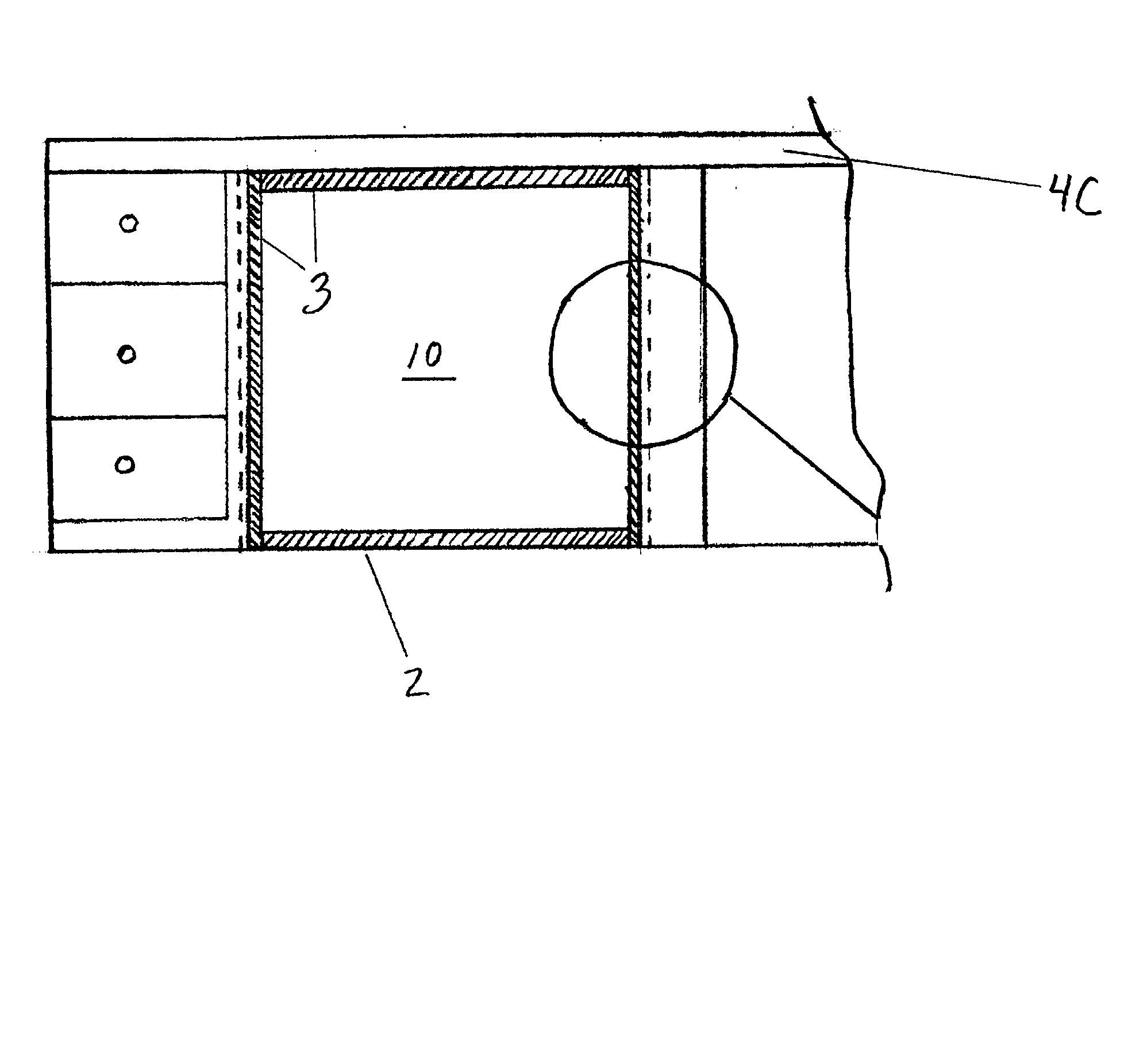

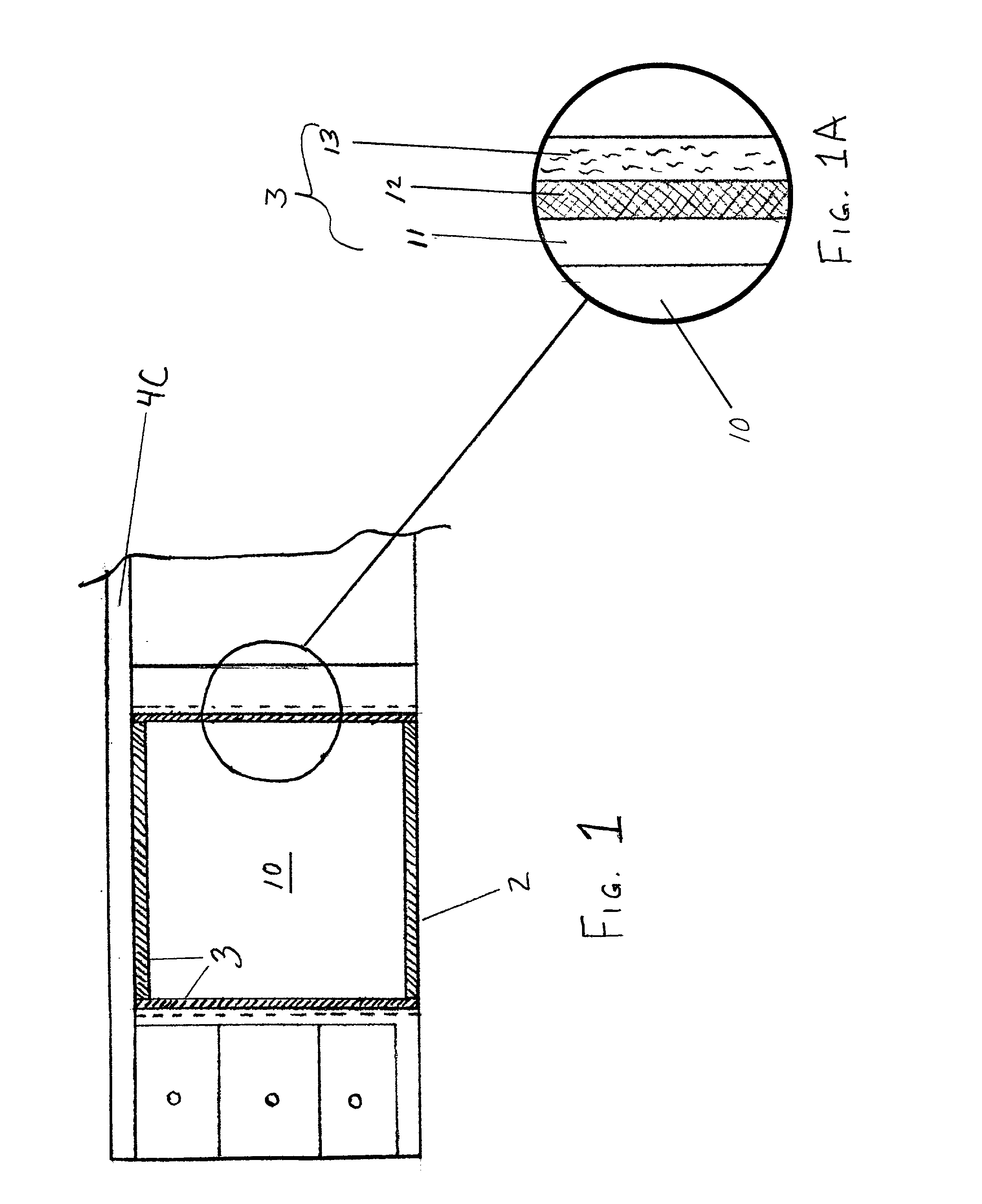

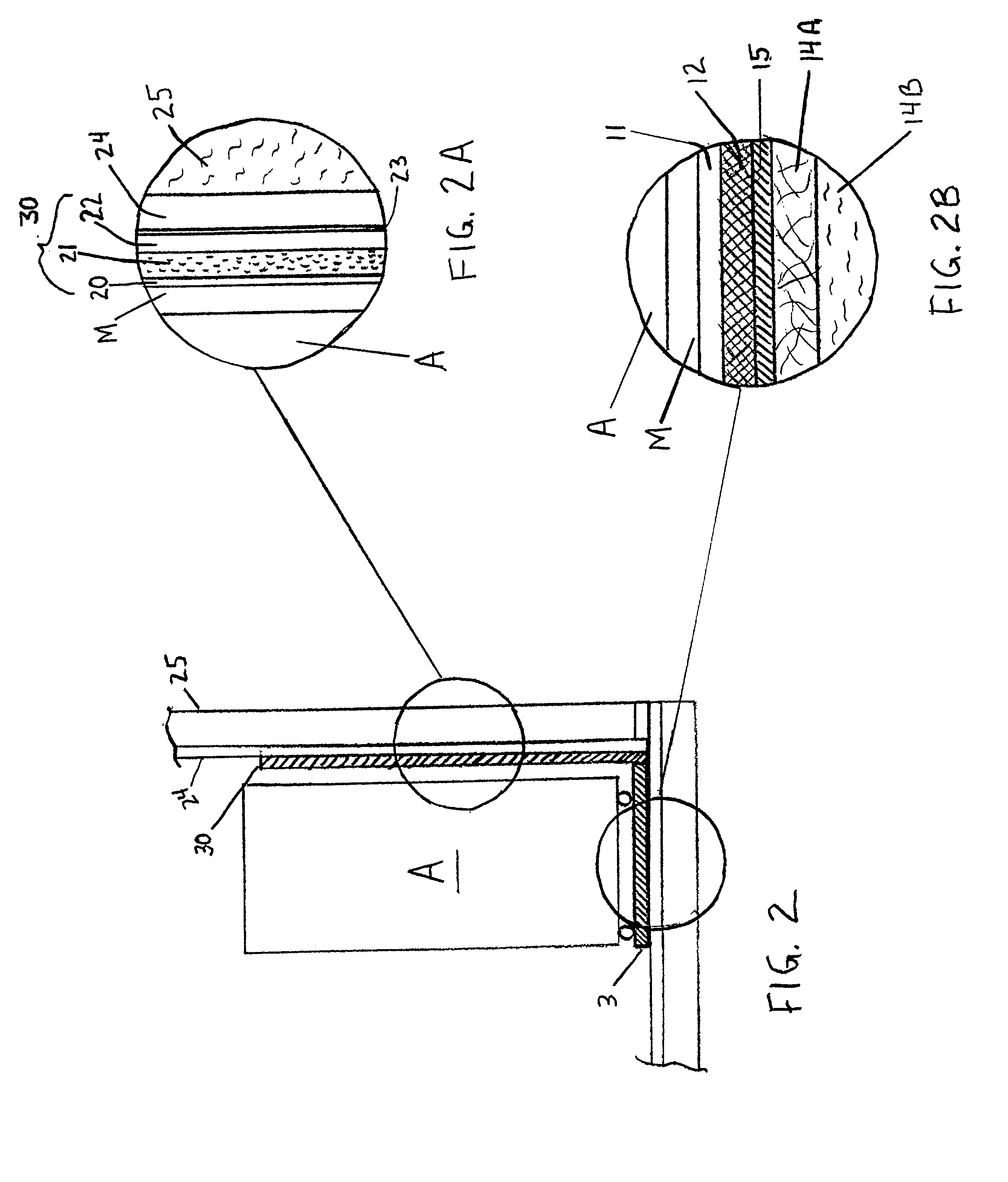

[0027] The components of this present invention will reduce the acoustic energy transmitted from the appliances to the kitchen environment by resisting the transmission of vibro-acoustic energy through the cabinetry, flooring and walls. The components of this present invention have been designed to isolate as well as dissipate vibro-acoustic energy. By isolating and dissipating the vibro-acoustic energy, the noise radiated into the kitchen will be reduced. This will improve the atmosphere of the kitchen and improve communication within the kitchen by lowering background sound levels due to appliances and other kitchen apparatus.

[0028] As discussed hereinabove, prior efforts have shown that this noise can be reduced with targeted, frequency specific, dissipation. However, one of the aspects of the present invention, in part, is that it has been determined that the transmission of vibro-acoustic energy can be controlled by the application of mass based treatments to the cabinets, isol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com