Structure including a plurality of cells of cured resinous material, method of forming the structure and apparatus for forming the structure

a technology of cured resin and structure, applied in the field of structure including a plurality of cells of cured resinous material, method of forming structure and apparatus for forming structure, can solve the problems of leakage or diffuse through the structure, contaminant of sensors and solar cell arrays, and loss of inflatant mass with increasing antenna siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

[0037] The present invention can satisfy the need or desire to form structures in place. Additionally, the present invention can fulfill the need to create lightweight high strength structures. In particular, the present invention can be utilized to form elongated lightweight high strength structures. While the present invention may be particularly useful in space, it may be utilized for terrestrial as well as undersea applications.

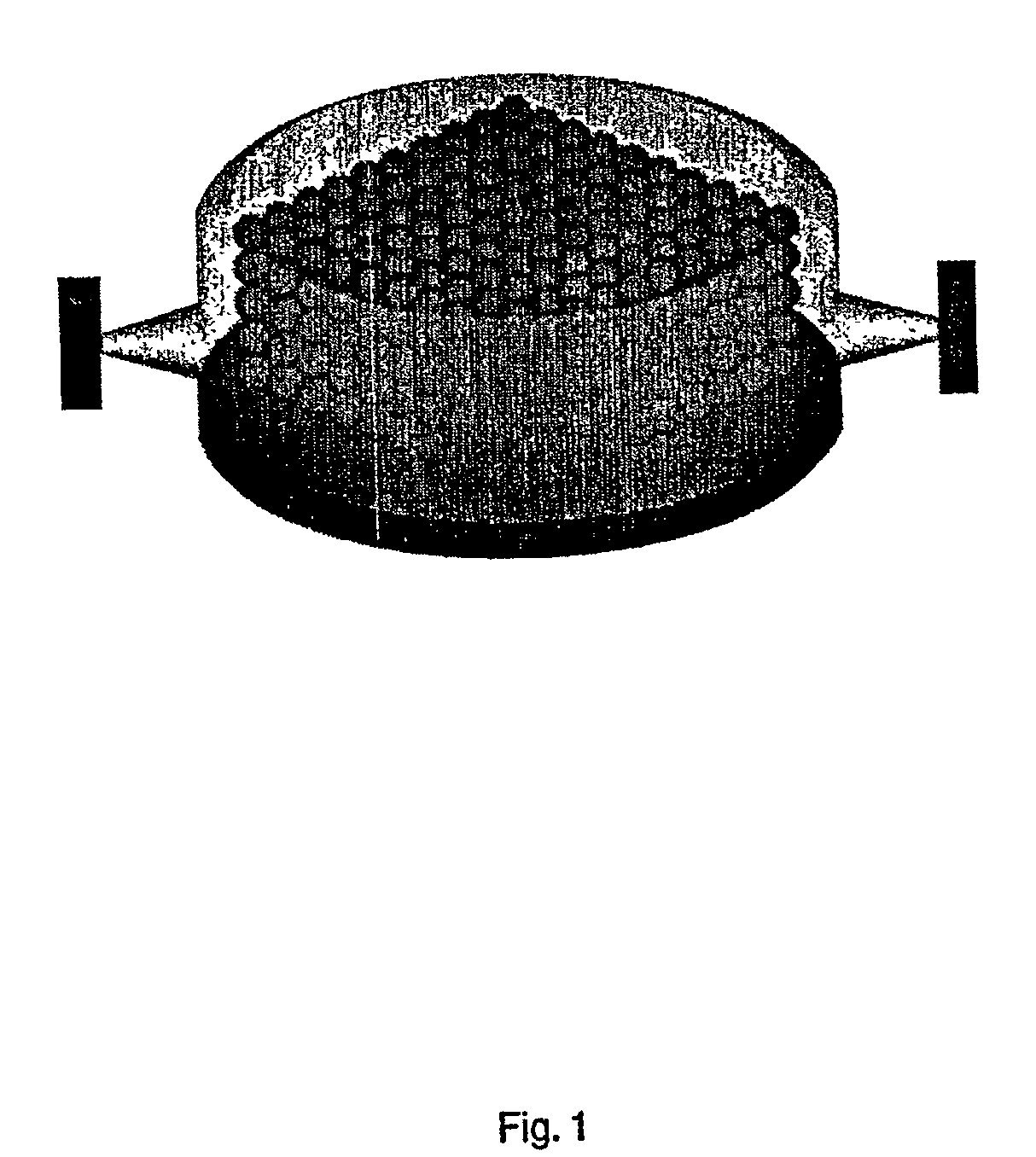

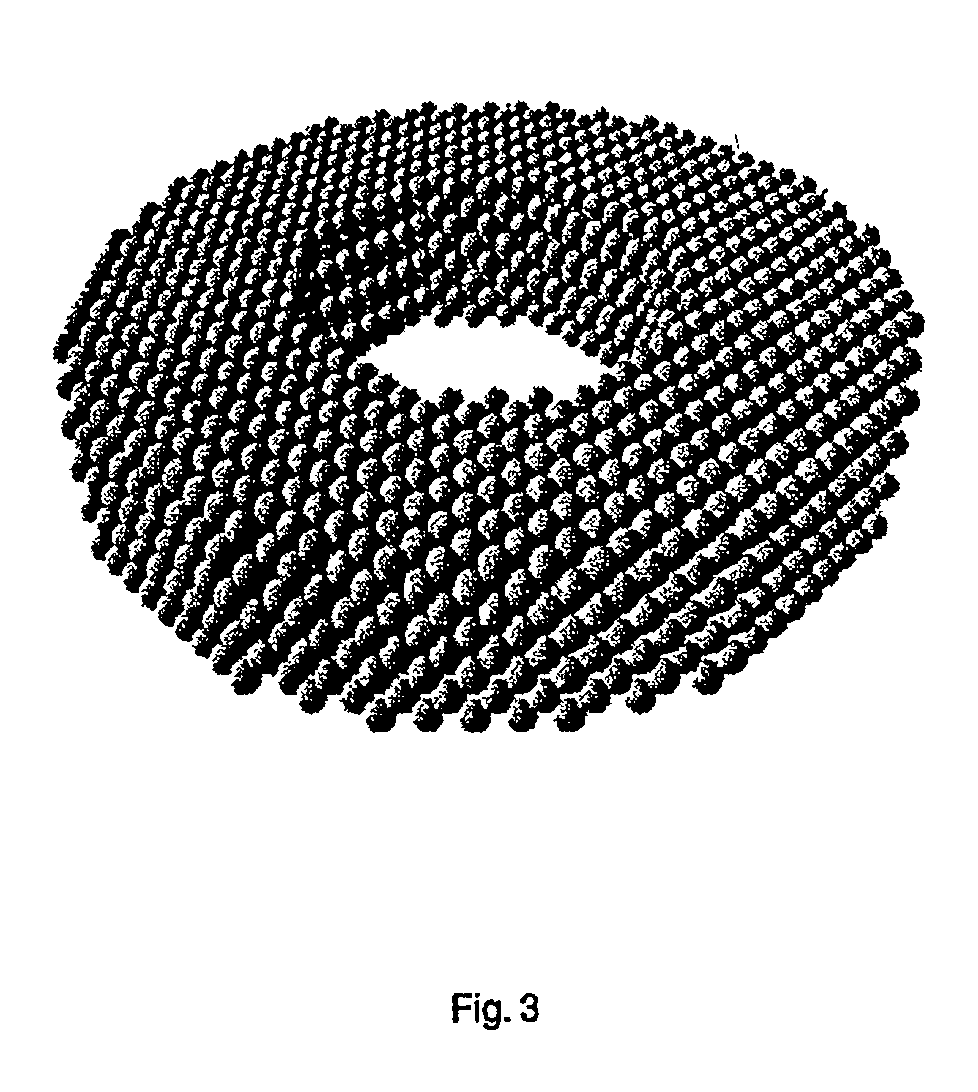

[0038] Structures according to the present invention include a plurality of cells of cured resinous material. The cells may be arranged in a plurality of planes. Each plane may include the same or a different number of cells. The cells may all be aligned with each other in a direction perpendicular to the planes. Alternatively, the cells may be arranged aligned in another direction. For example, the cells in one plane could be arranged with their centers spaced one-half cell diameter away from the cells in an adjacent plane. The cells could be aligned in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| area mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com