Method and apparatus for lifting, leveling, amd underpinning a building foundation

a technology for building foundations and methods, applied in foundation engineering, bulkheads/piles, construction, etc., can solve problems such as excessive stress on the foundation, improper penetration angle, and insufficient depth of screw anchors, and achieve the effect of leveling the foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

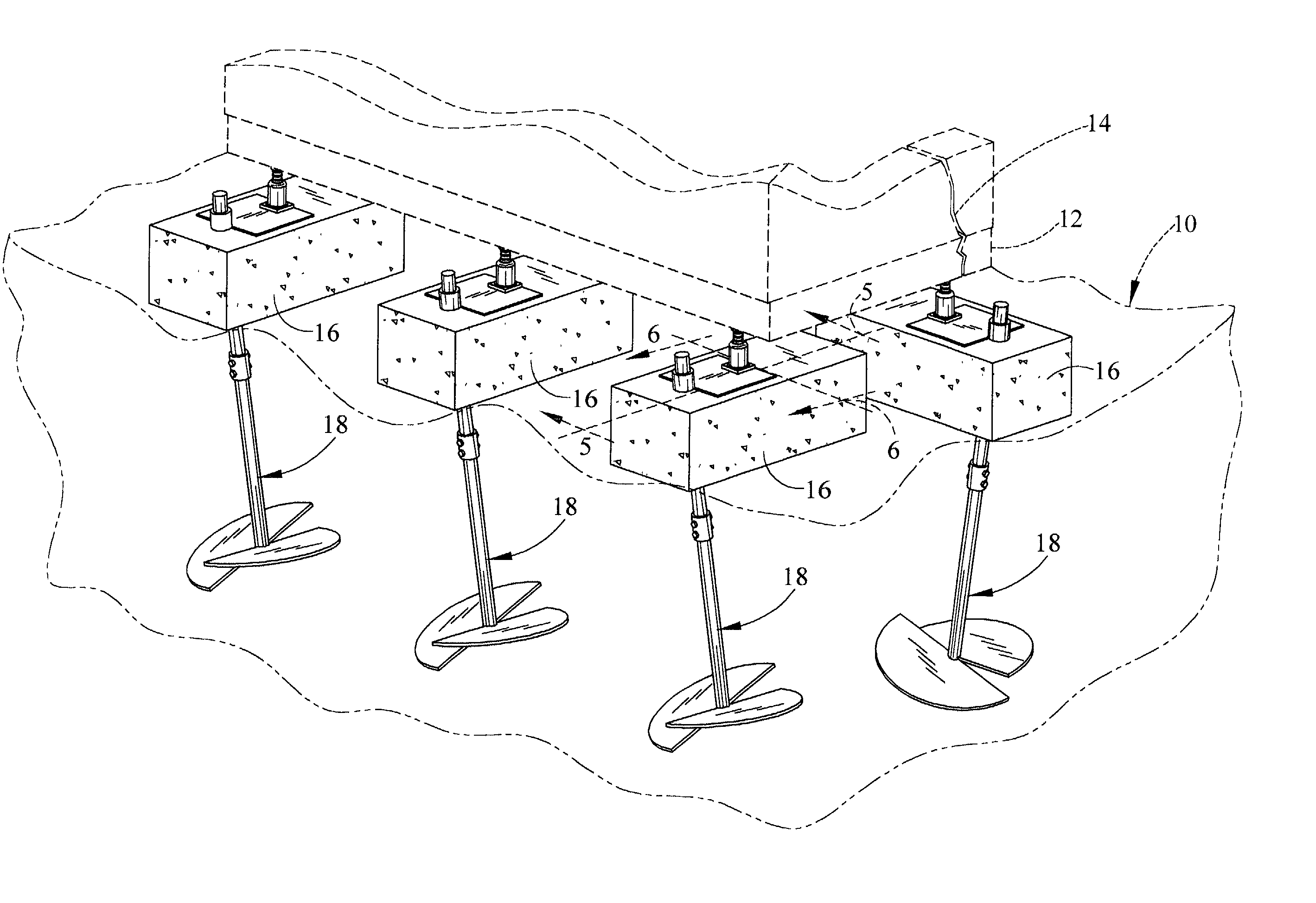

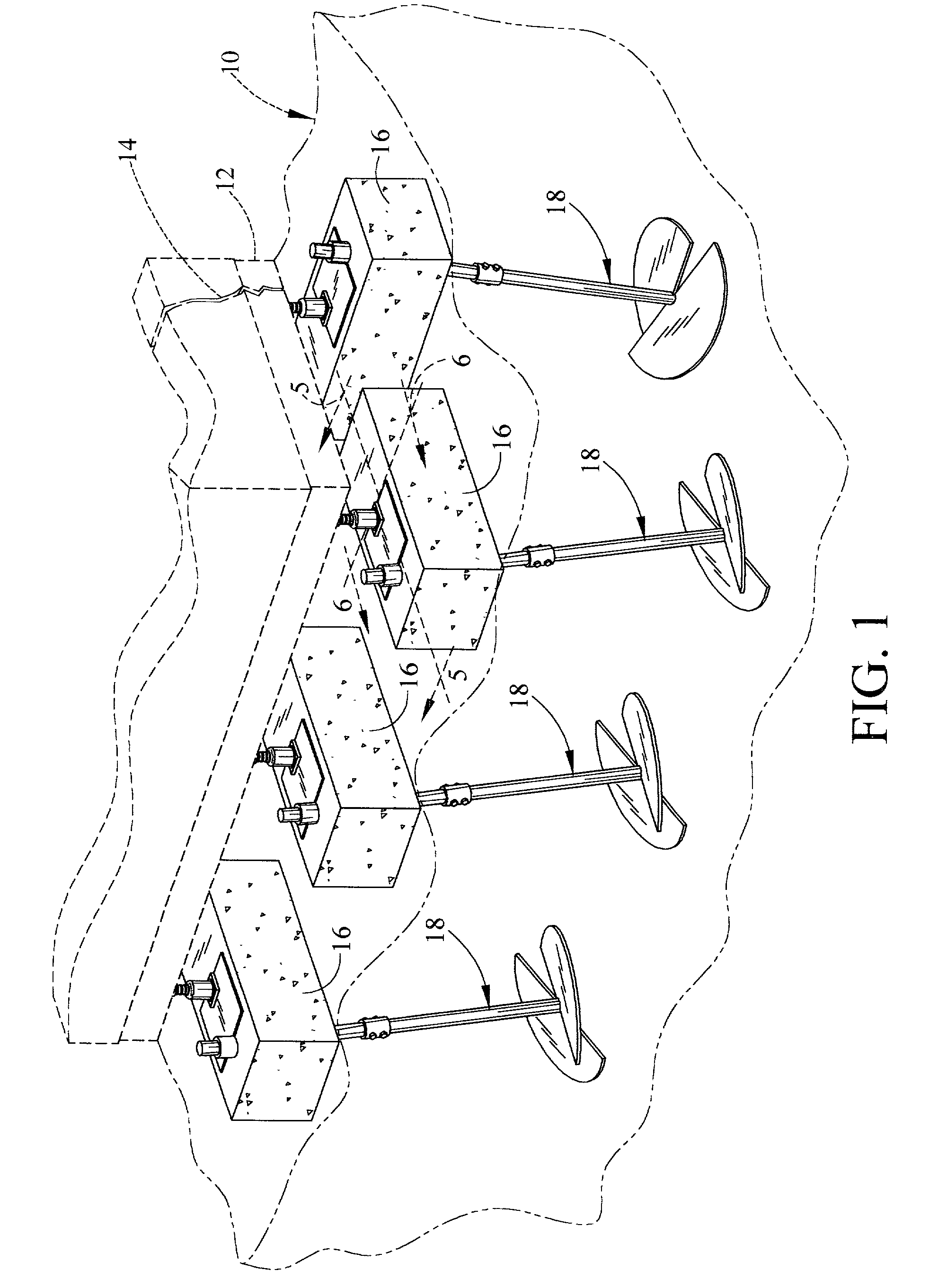

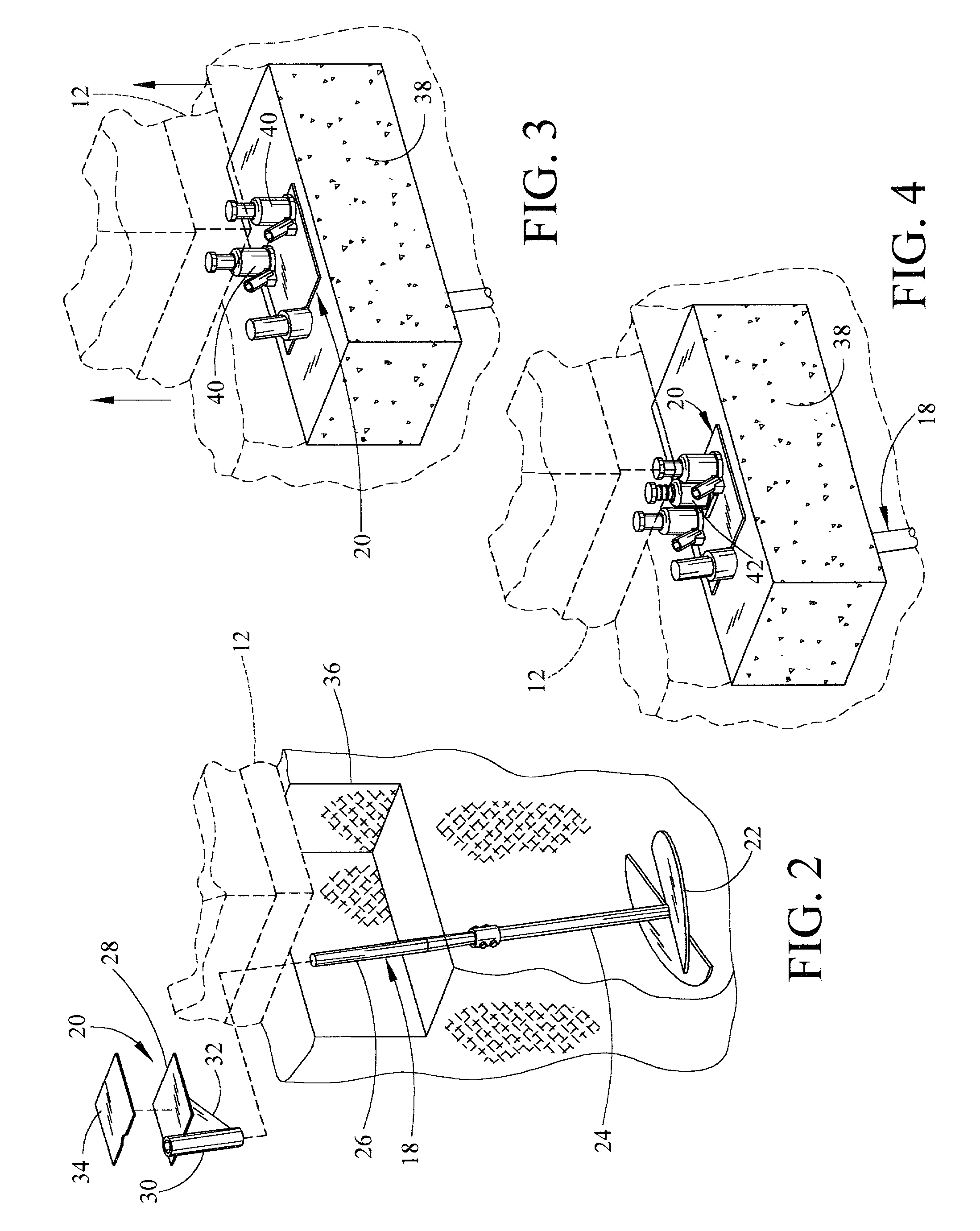

[0014] As illustrated in FIG. 1, foundation leveling is usually required as a result of movement in the soil 10 providing support for the foundation. Such movement often results in cracks 14 in the floor slabs 12, etc. In such cases it has been found that floating piers 16 stabilized by a screw anchor 18 located at strategic points around the foundation 12 are very effective and inexpensive in raising and leveling a foundation if applied in a unique manner using a unique jack plate assembly 20 as seen in FIG. 2. The leveling apparatus includes the screw anchor assembly 18, which is comprised of the screw blade portion 22 and the shaft portion 24 which may be extended by coupling additional shaft lengths as necessary to allow the anchor to reach a stable earth formation. Making the screw auger blades or flighting 22 oversized, relative to general practice, typically in the range of 18 to 24 inches in diameter, stability may be achieved at a much shallower depth. The apparatus further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com