Prosthetic foot having curved ankle section

a foot and ankle technology, applied in the field of foot prostheses, can solve the problems of significant deficiencies in devices, long, heavy weight of prosthesis components, etc., and achieve the effect of natural stride and resilience of gai

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

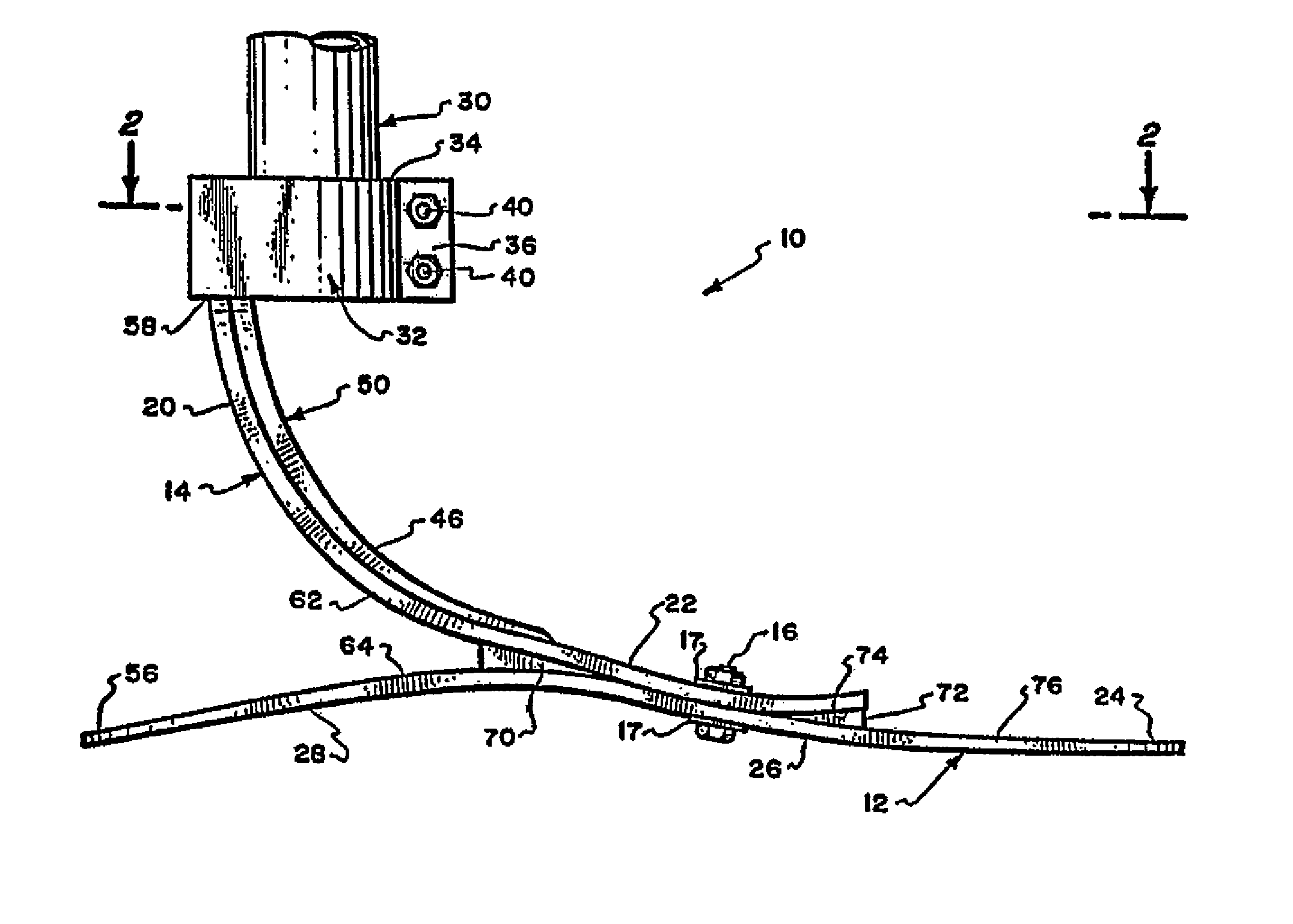

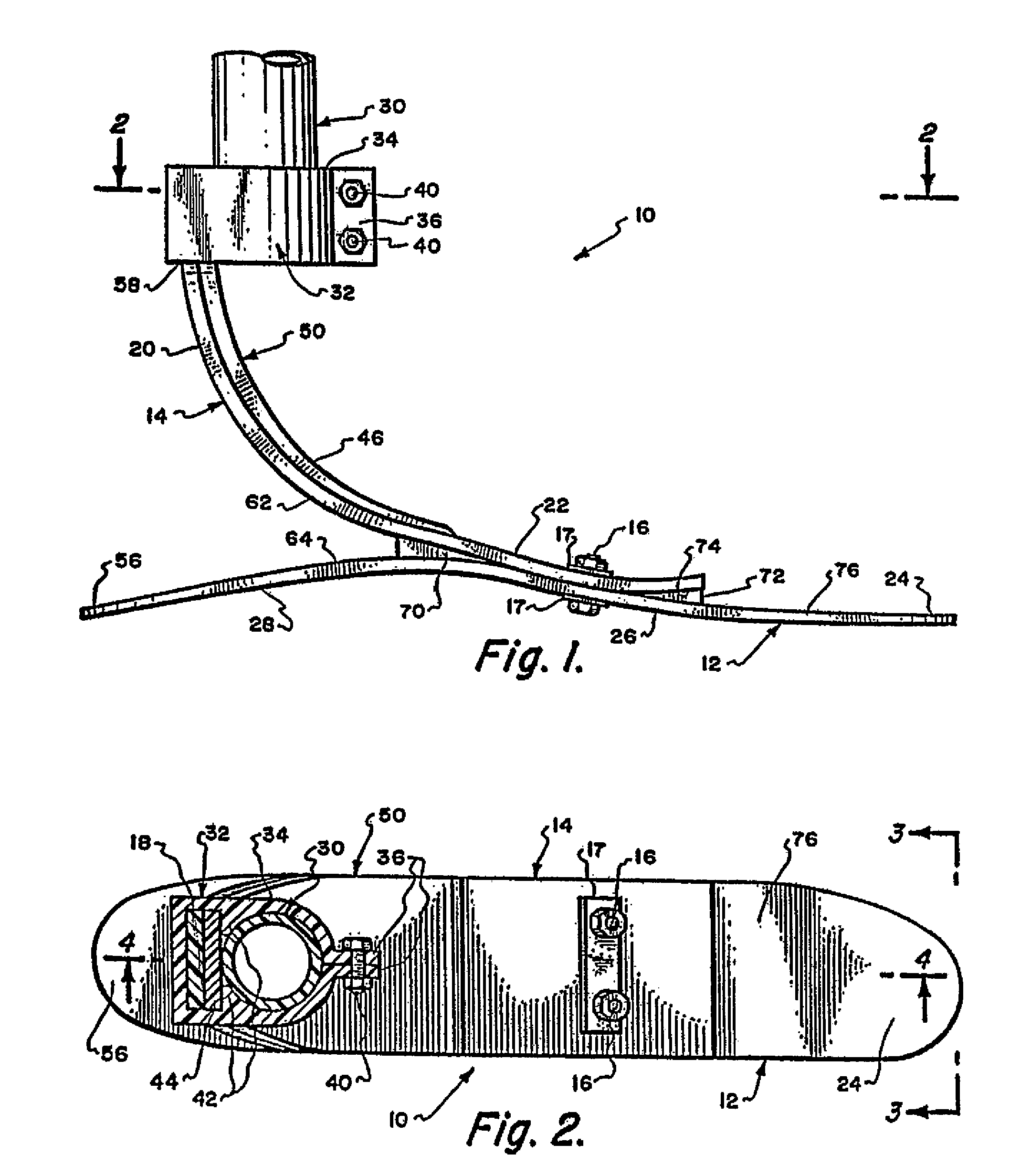

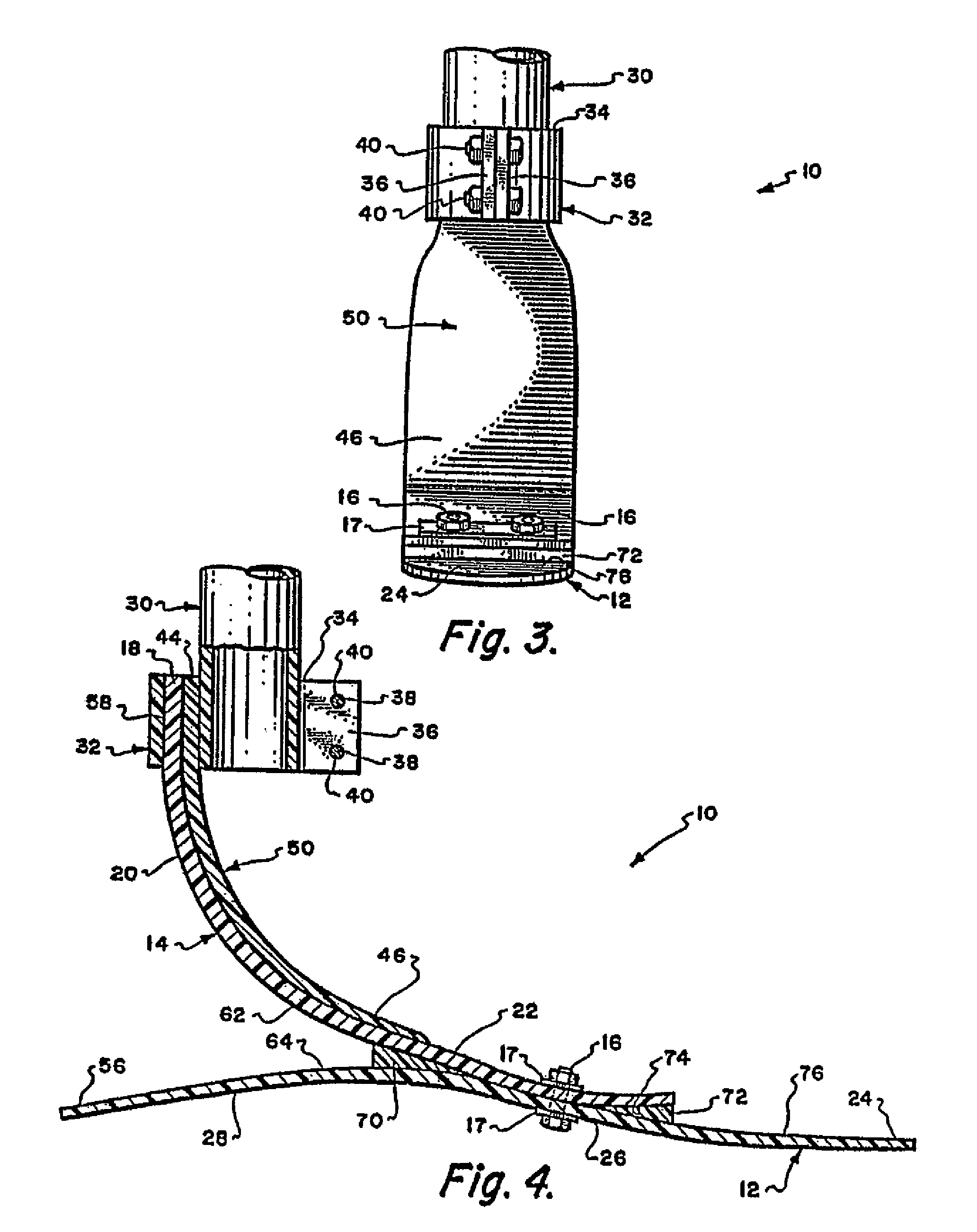

[0030] Referring to the drawings, and particularly to FIGS. 1 and 2 thereof, I show a foot prosthesis 10 constructed in accordance with the teachings of the invention and including a foot portion 12 and an ankle portion 14 operatively and demountably connected to each other by bolt and nut combinations 16 associated with loadtransmitting metallic plates 17. If indicated, the foot and ankle portions can be permanently secured to each other, as by epoxy adhesive, an intermediate resilient member, or the like.

[0031] The ankle portion 14 of the prosthesis 10 includes a substantially rigid upper attachment section 18, FIG. 4, a curvilinear ankle section 20, and a lower attachment section 22. The sections 18, 20, and 22 of the ankle portion 14 are formed integrally with one another and simultaneously by a plurality of Juxtaposed, shaped laminae embedded in a hardened, flexible polymer.

[0032] The attachment section 18 has a rearward surface 58, as shown in FIG. 4, and a forward surface sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com