Artificial nail tips

a nail tip and artificial technology, applied in the field of artificial nail tips, can solve the problems of tip cracking or weakening, discomfort for the wearer of the nail tip, and is normally not strong enough to withstand, so as to maintain the structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

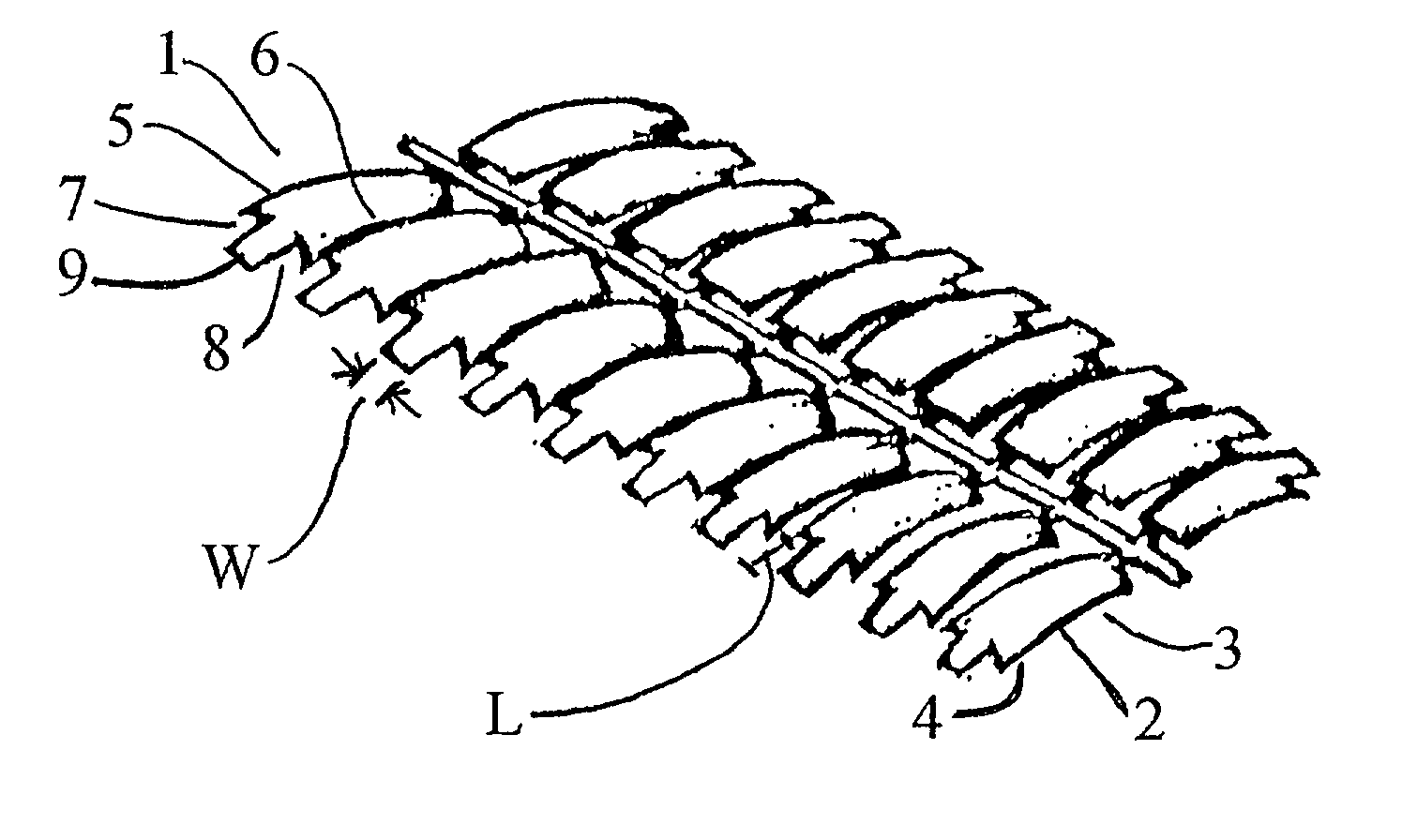

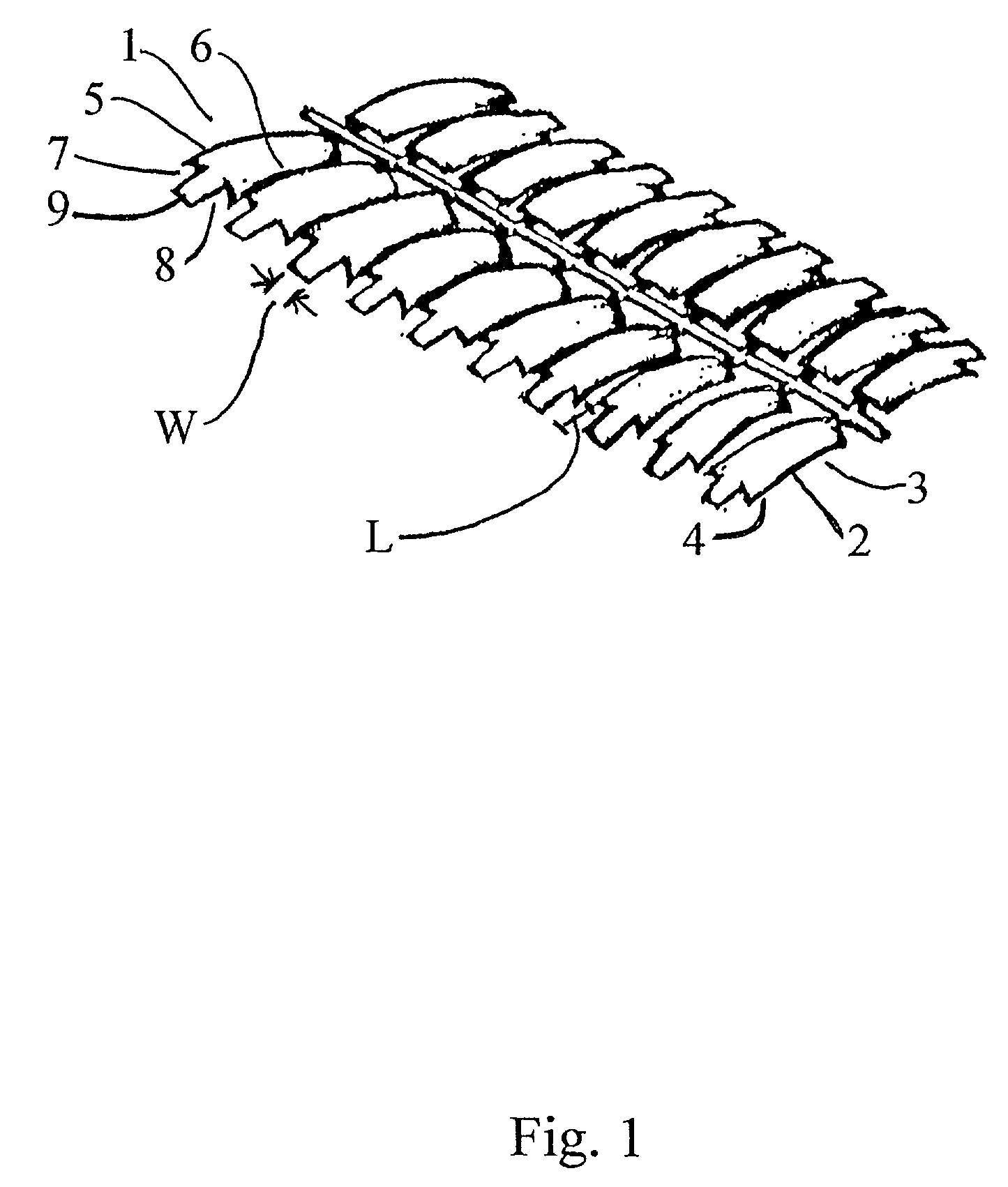

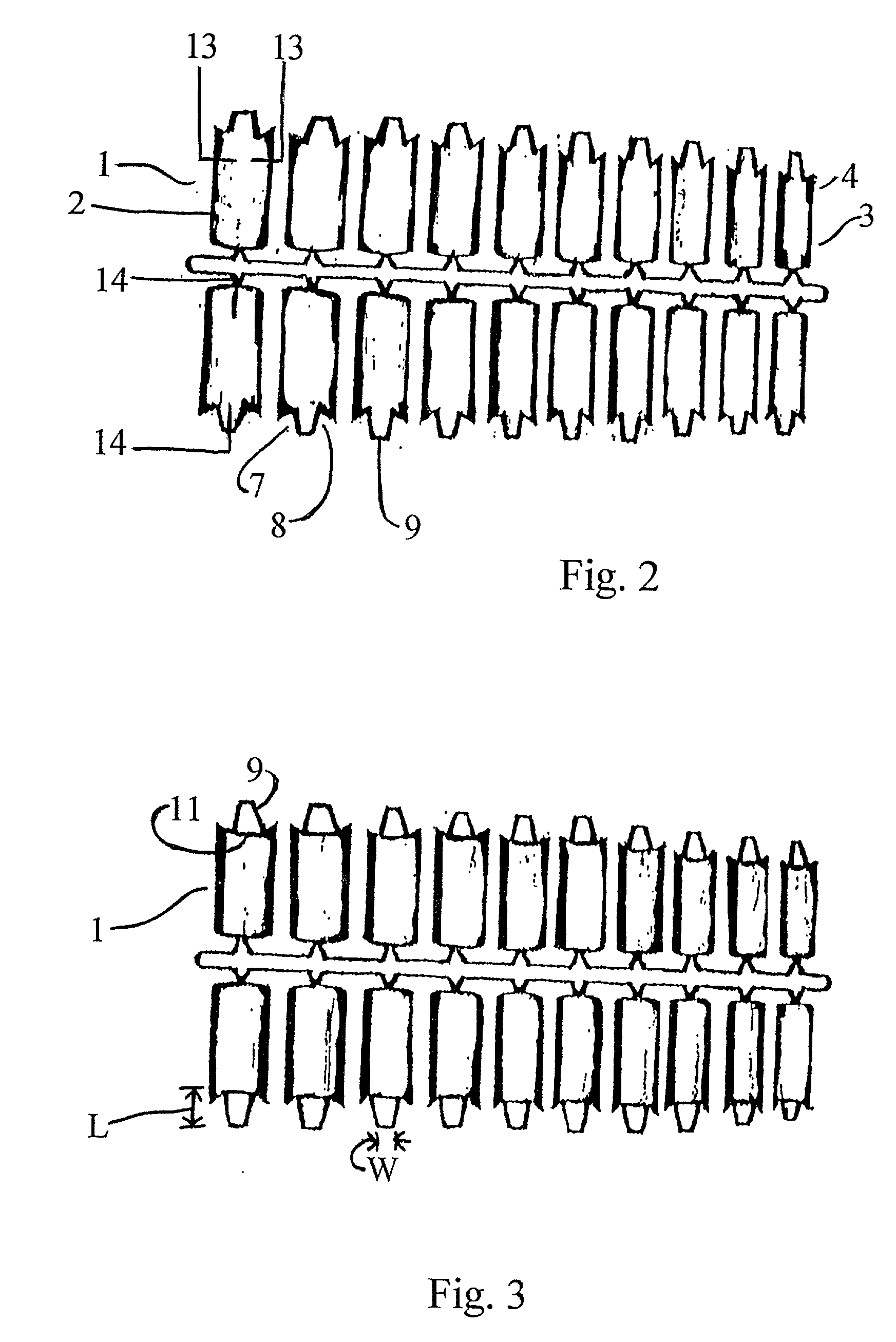

[0033] Referring first to FIG. 1, the current invention involves a nail tip 1 that has a body member 2, a front portion 3 of the body member 2, a back portion 4 of the body member 2, a first side 5 and a second side 6, a first cutout portion 7 on one side of said back portion 4 and a second cutout portion 8 on the opposing side of the back portion 4. The first cutout portion 7 and the second cutout portion 8 define a thinned attachment wing area 9 to provide a more flexible attachment area and, therefore, a more conforming fit of the nail tip 1 to a variety of natural nails. The first cutout portion 7 and second cutout portion 8 create the narrower attachment wing area 9 that has a more aesthetically pleasing look and results in a stronger finished nail product with less damage to the wearer's natural nail. In the preferred embodiment, the first cutout portion 7 and second cutout portion 8 of the nail tip 1 are achieved by pre-molding the nail tip 1 to include such portions; they ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com