Apparatus and method for manufacturing bread

a technology of apparatus and bread, applied in the field of apparatus and method for manufacturing bread, can solve the problems of air bubbles rising between layers and degrading quality, and achieve the effect of efficient production of high-quality bread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

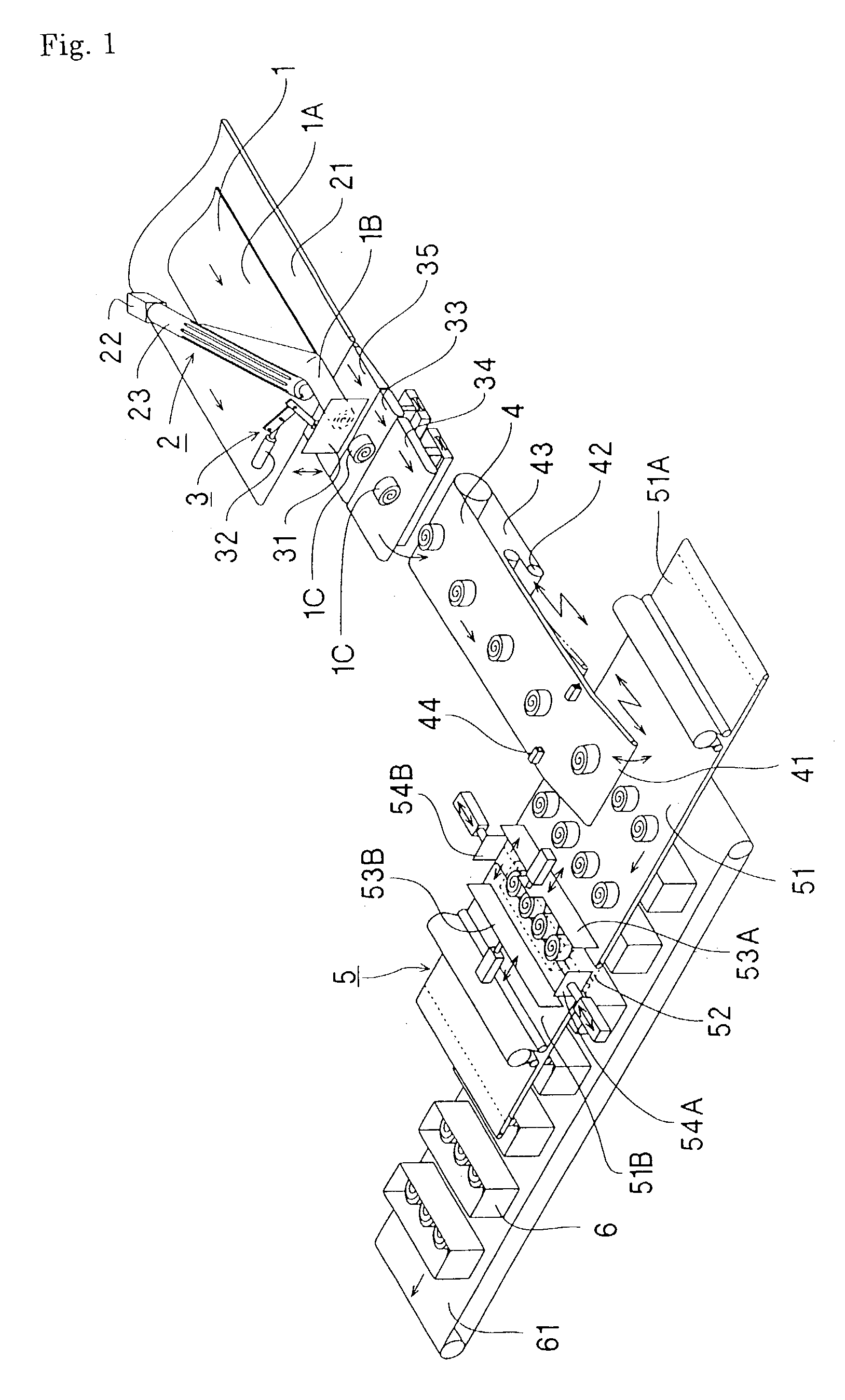

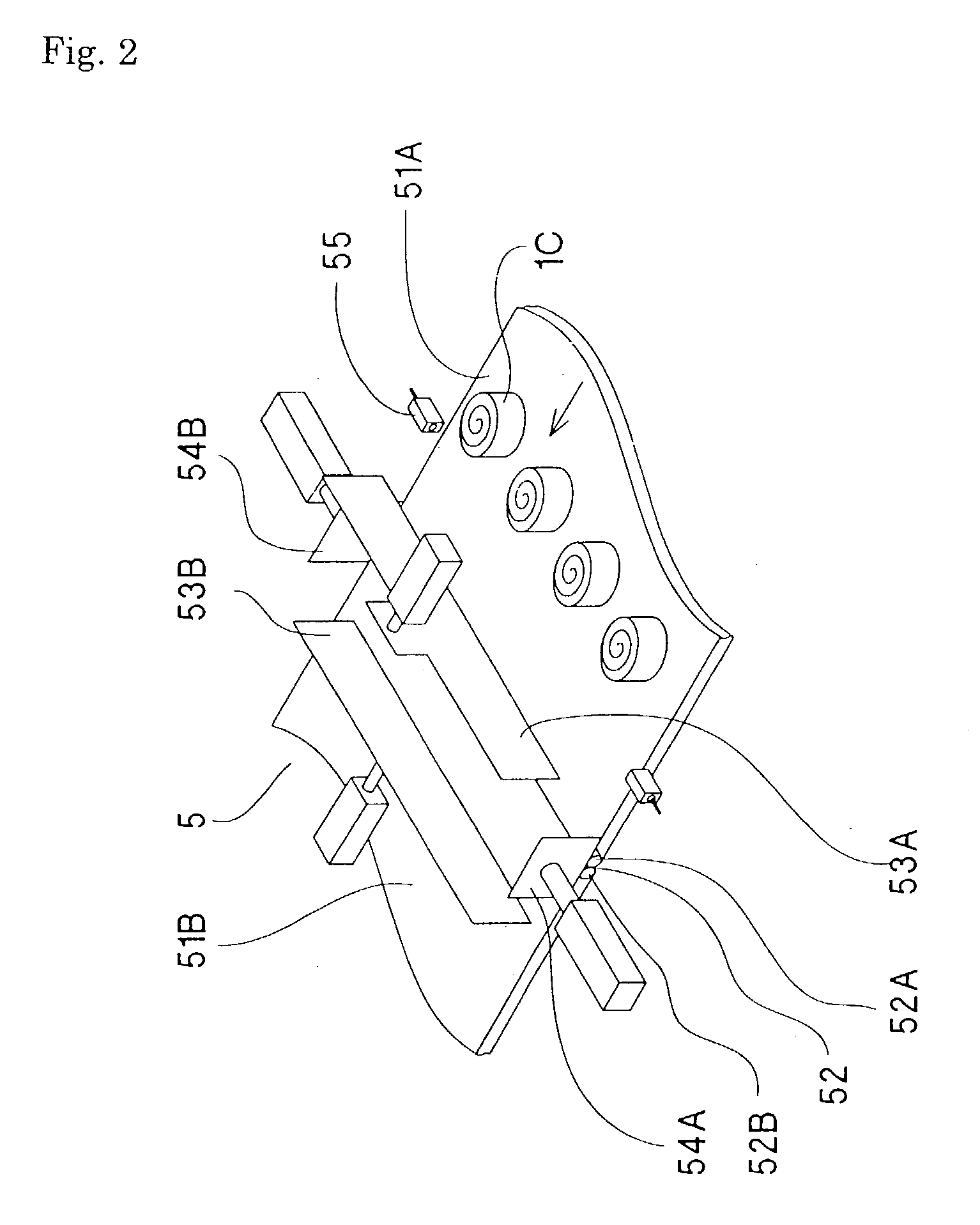

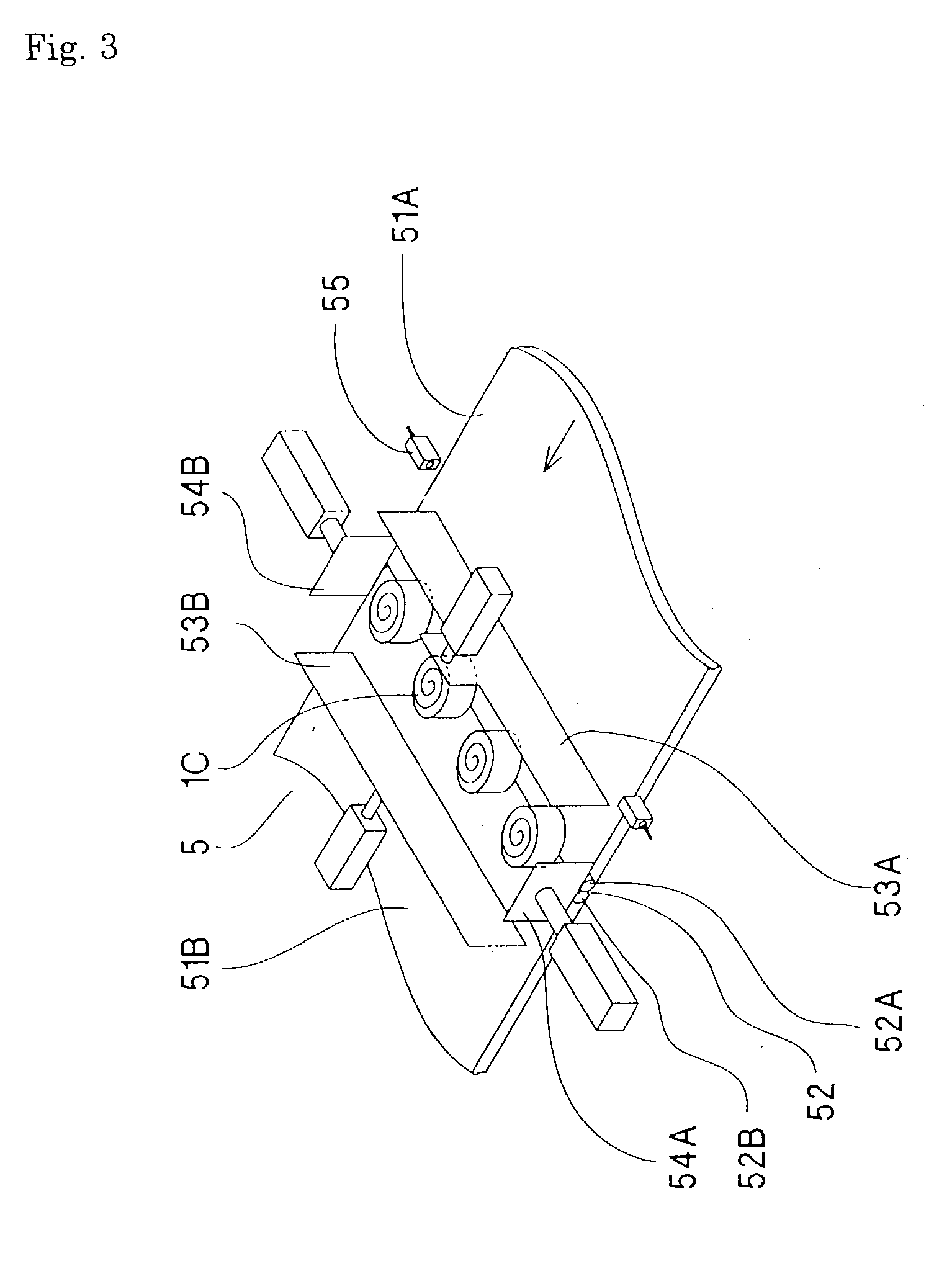

[0028] First, the present invention is explained based on an embodiment. FIG. 1 is a perspective view of an apparatus for manufacturing the bread of this invention. In this embodiment, a conveyor 21 conveys a continuous sheet of bread dough 1, a forming apparatus 2 forms the continuous sheet of bread dough 1A into bar-like dough 1B by rolling the sheets, and then a cutting apparatus 3 cuts the bar-like dough 1B into bar-like pieces of dough 1C having a predetermined size. The bar-like pieces of dough 1C are transferred to a placing apparatus 5 by a transfer conveyor 4. Then a predetermined number of the bar-like pieces of dough 1C are placed in a baking mold 6 by the placing apparatus 5.

[0029] Next, this embodiment is described in detail.

[0030] The continuous sheet of bread dough 1A is prepared in advance by any dough-sheet-forming apparatus that is well known. For example, a stretching apparatus for food dough provides sheets of bread dough (Japanese Patent Application No. 2002-286...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com