Linkable clip

a linkable and clip technology, applied in the field of clips, can solve the problems of not being able to be attached to anything else, sealing the balloon, and generally regarded as fiddly and difficult to manage,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

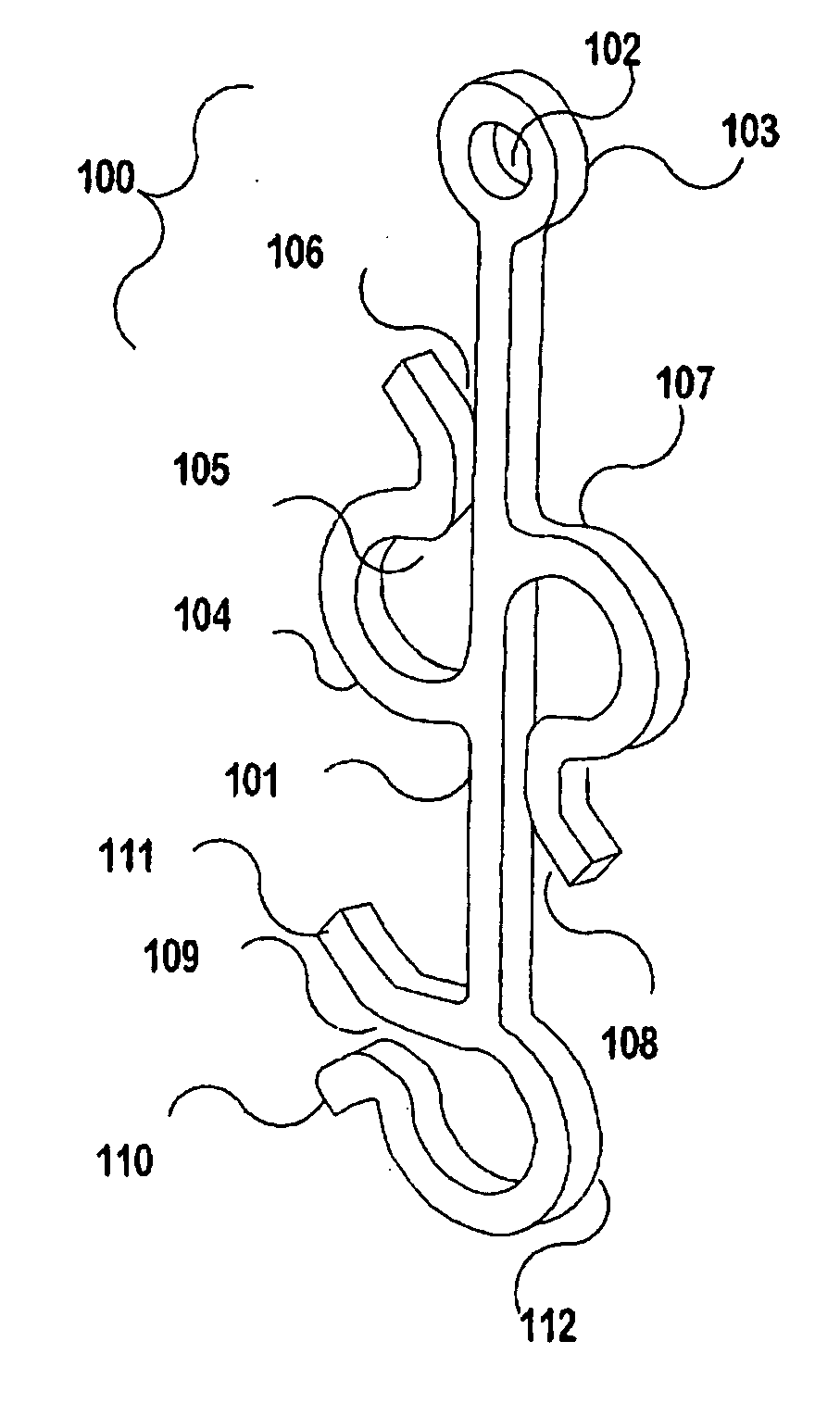

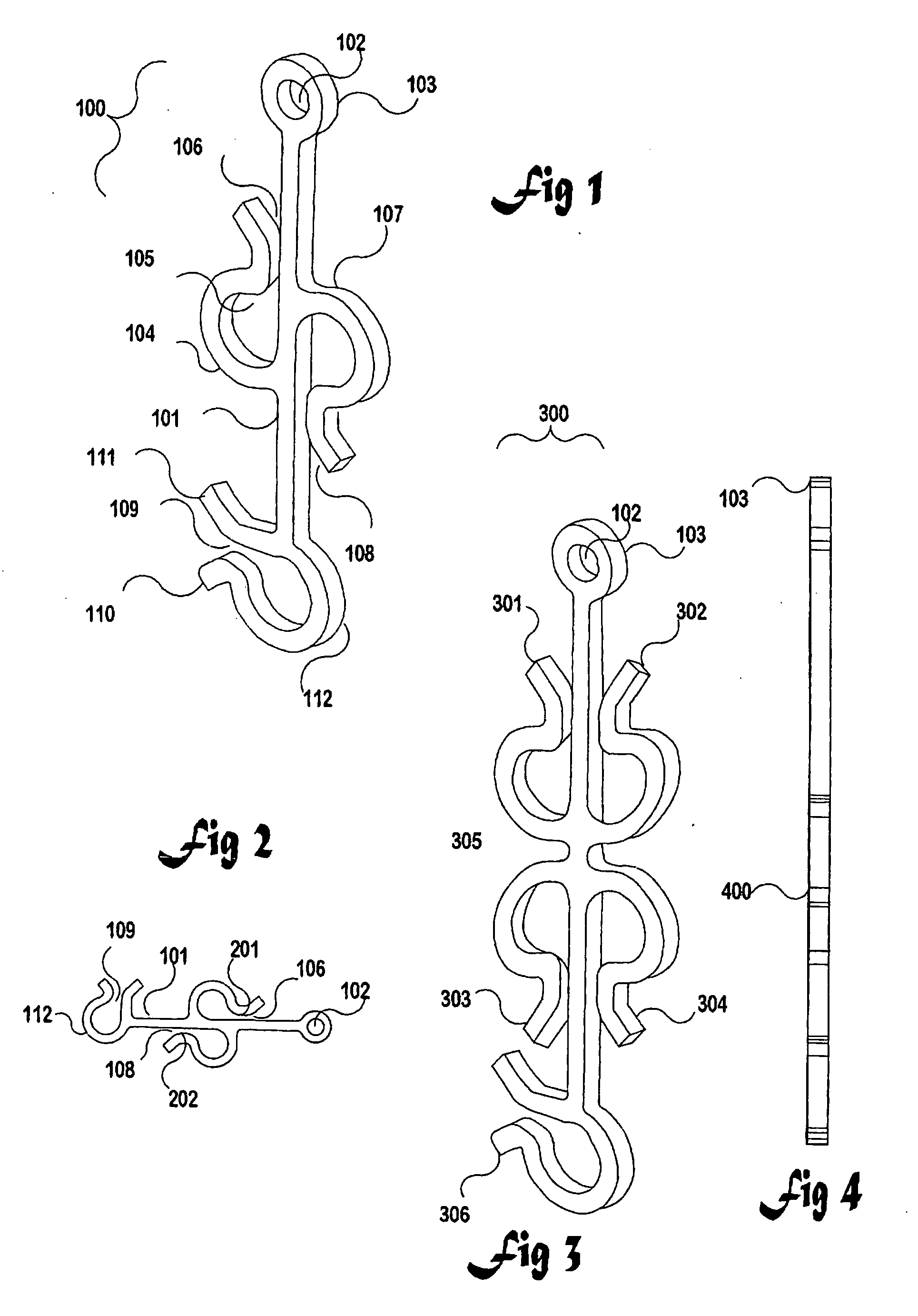

[0036] The clip shown in oblique view in FIG. 1 is an injection-moulded shape made of a stiff though bendable (that is, tough but not brittle) plastics material. A typical (example) length for the straight section 101 of FIG. 1 is about 39 mm. A typical cross section is about 2.5 mm square, or an equivalent area in circular profile. Although the profiles shown in the prototype Examples are for items of constant thickness the moulds may be shaped from point to point so that the stiffness of the resulting clips is optimised in relation to material consumed, preferably while retaining the easily releasable attributes of the designs shown.

[0037] Suitable plastics materials are selected from the available range of injection-mouldable polymers currently including polypropylene, ABS, polycarbonate or other blends (alloys) of polymers, as will be well known to one skilled in injection moulding. Fillers and dyes may be used, even fluorescent dyes and phosphors, in order to make the clips mor...

example 2

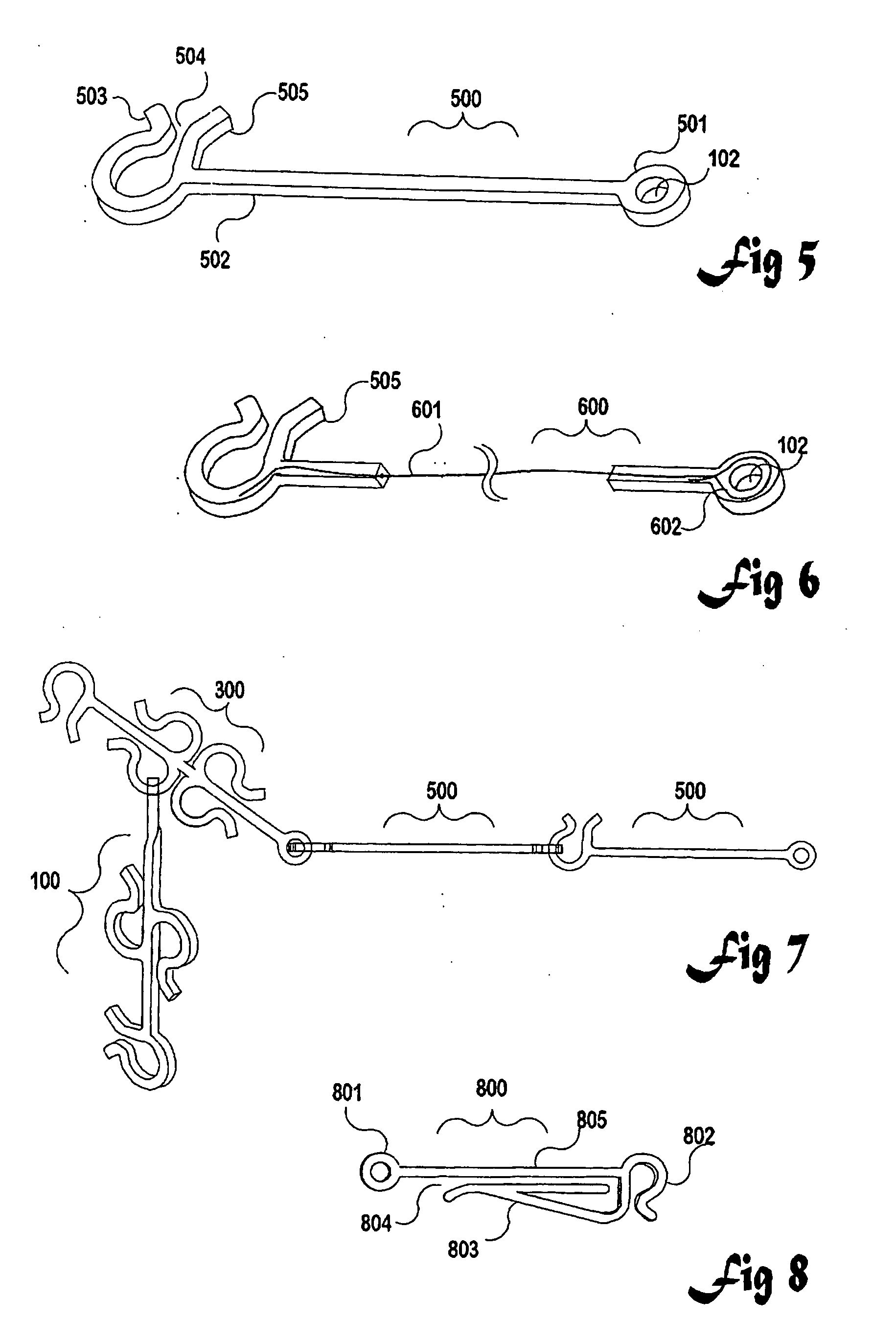

[0045] This earlier version of the clip is a plastic item, preferably 55 mm long, 12 mm wide and 2 mm thick. FIG. 8 is a diagram of this version 800 of the clip showing a preferred shape, based on an elongated body 805. In this version we had constructed a separate form of holding structure 803 for balloon gripping as opposed to linking (by 802) to other clips (see FIG. 11 in which 5 clips (800) are shown linked together). An entrance to the gripping section is shown at 804. This version illustrates the variety of jaws that may be provided within the basic structure of the clip in order to hold different articles.

[0046] The functional characteristics of the elongated gap are defined partly by the shape of the clip and also by the physical characteristics (deformability) of the injection moulded plastics used to make the clip. As for the earlier set, the hook shape at 802 comprises either a second site to hold a balloon, or one member of a coupling to join to another linkable clip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com