Disfigure-resistant plastic-string mat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

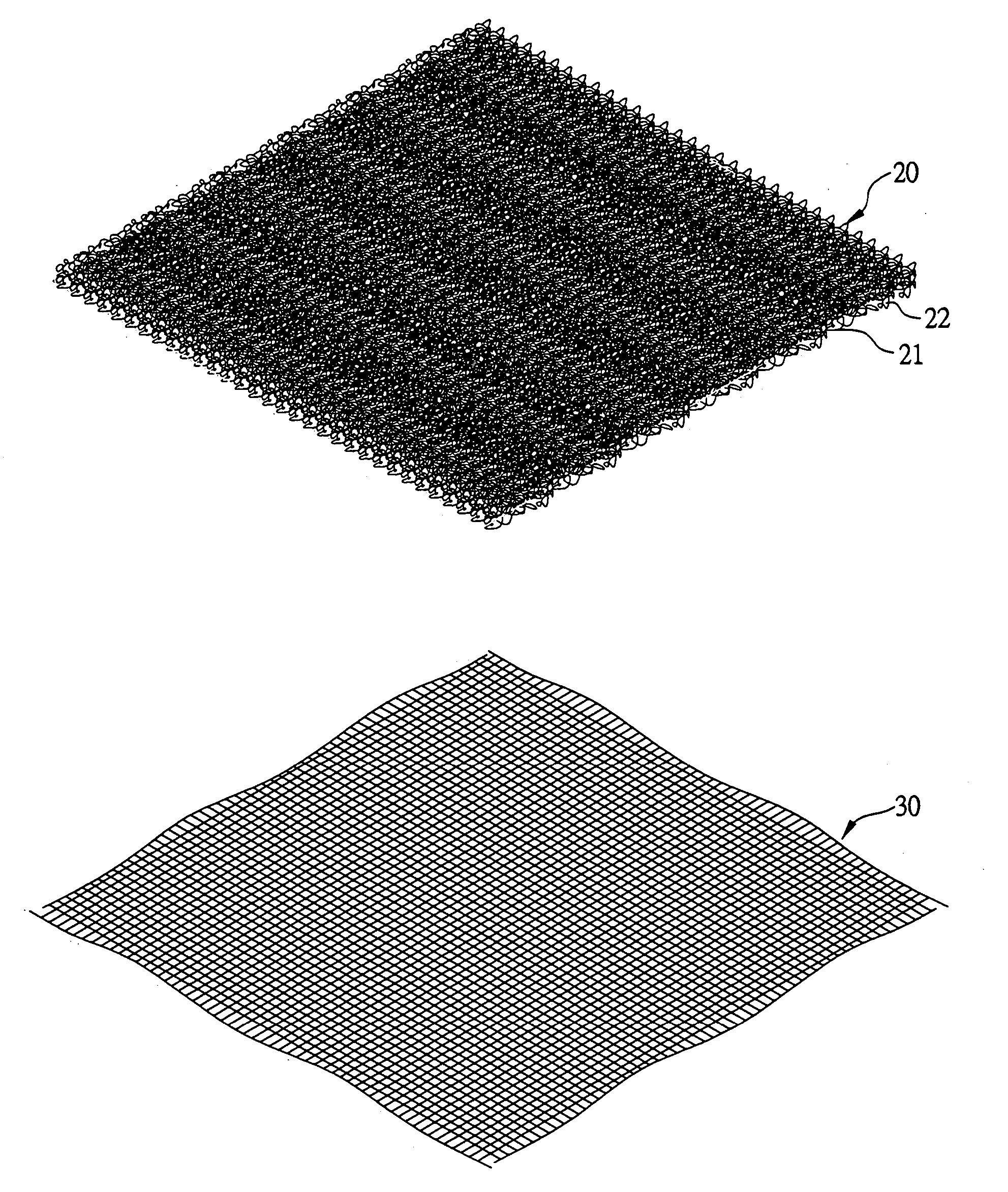

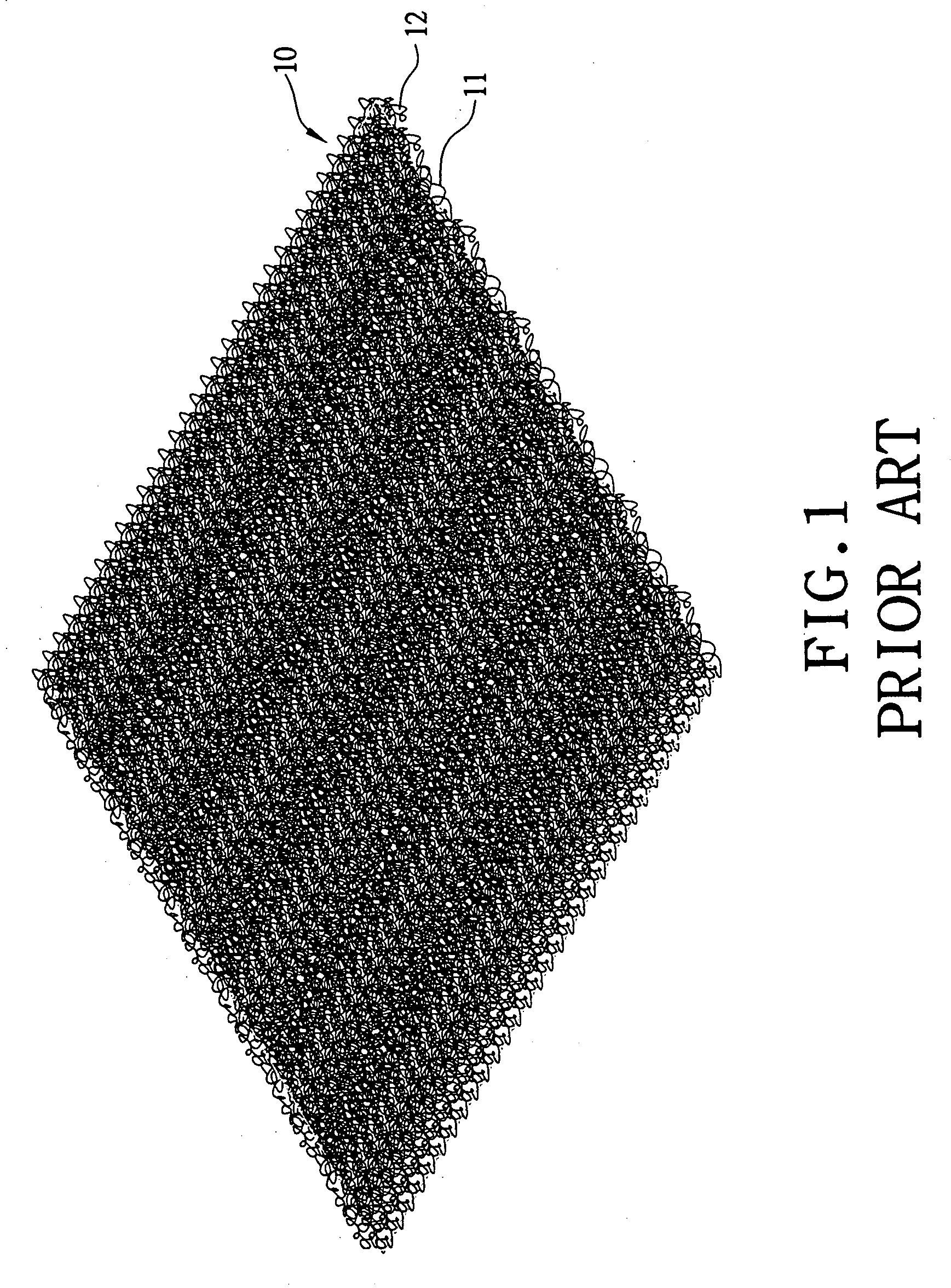

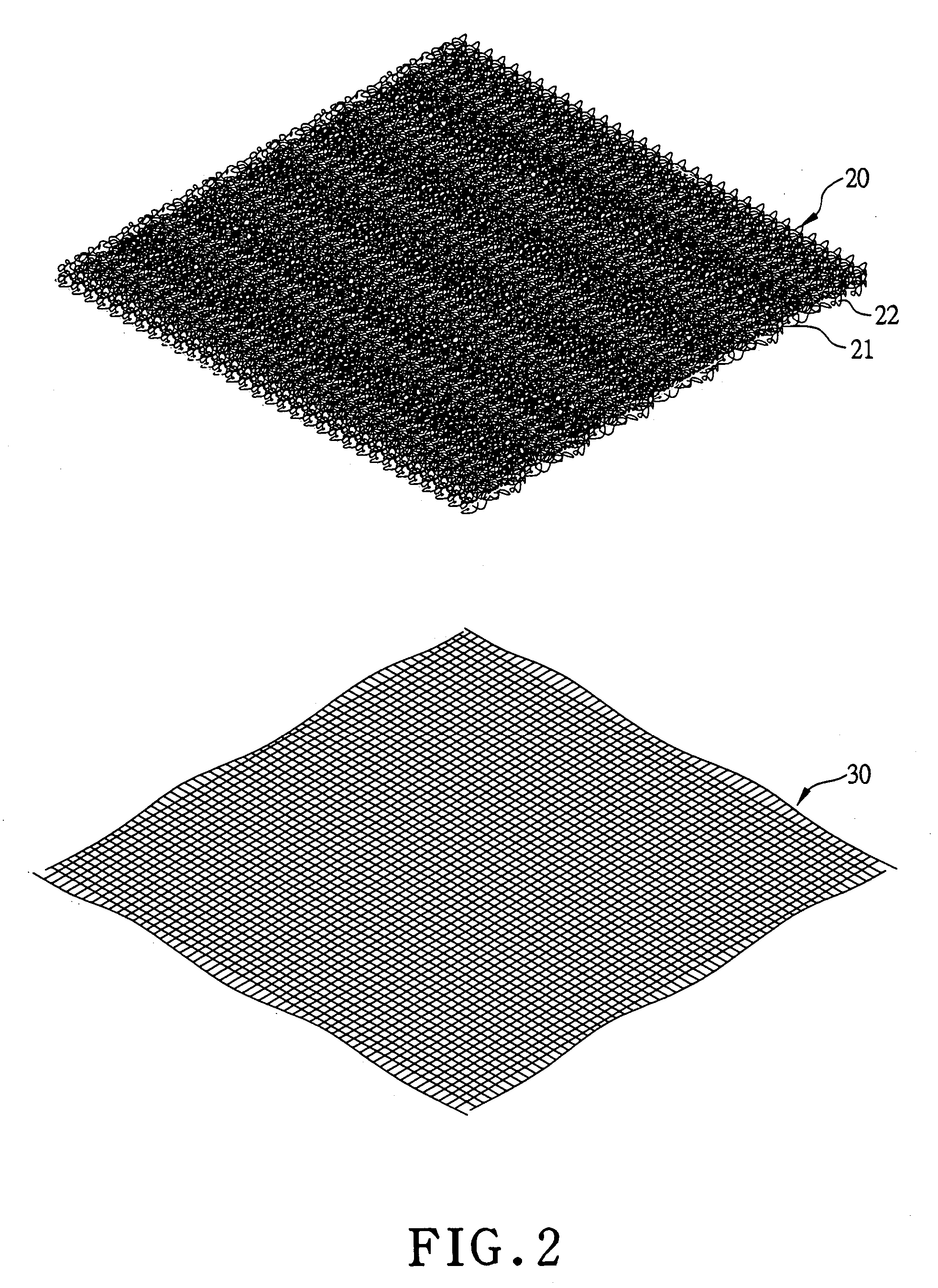

[0014] a disfigure-resistant plastic-string mat in the present invention, as shown in FIGS. 2 and 3, includes a scraping layer 20 and a lattice-shaped net layer 30.

[0015] The scraping layer 20 has a certain thickness, made of high-molecule plastic elastic strings 21 under high temperature and high pressure and cooling, and the plastic strings are formed into countless rings piled up randomly, interlocking and intercrossing with one another and naturally defining countless gaps among them.

[0016] The lattice-shaped net layer 30 is woven with strong PET fiber and fused under the scraping layer 20 under high temperature, having an anti-tension as strong as in the scope of 500-10,000 N / m, and its surface immersed in plastic solution 32 homogeneous with the scraping layer 20 so that the lattice-shaped net layer 30 may fuse with the scraping layer 20 under high temperature and then cooled to firmly combined with the scraping layer 20, without need of using adhesive.

[0017] As the lattice-sh...

second embodiment

[0018] Further, the disfigure-resistant plastic-string mat is shown in FIG. 4, in which a cushion layer 40 is added to be adhered under the lattice-shaped net layer 30, preventing the mat from slipping.

[0019] In short, the mat according to the present invention is formed with the scraping layer and the lattice-shaped net layer fused under the scraping layer, provided with advantages of not easily contractible property and excellent counter tensibility to make it washable in a washing machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force constant | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com