Reduction spiral spring for tubing paraffin removal of pumping well

The technology of coil spring and oil well tubing is applied in the field of variable diameter coil spring, which can solve the problems of large up-and-down movement resistance of sucker rod, small oil flow channel, short service life, etc. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

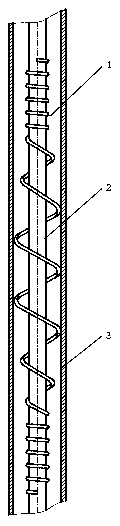

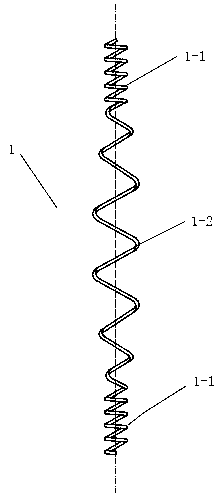

[0021] Implementation 1: see figure 1 with figure 2 A variable-diameter coil spring for removing wax from oil pipes in pumping wells is shown, including a body 1. The body is a coil spring made of elastic wire, which is fitted on the sucker rod 2 in the pumping well, and is connected with the pumping rod 2. Corresponding to the oil pipe 3 in the oil well, the body 1 is composed of a small-diameter section coil spring 1-1 connected with a large-diameter section coil spring 1-2, and the inner diameter of the small-diameter section coil spring 1-1 is slightly smaller than the oil pump The diameter of the rod 2, the outer diameter of the large-diameter segment coil spring 1-2 is slightly smaller than the inner diameter of the oil pipe 3. The middle part of the body 1 is the large-diameter helical spring 1-2, and the two ends are the small-diameter helical springs 1-1 respectively. The body 1 is made of an elastic wire with a circular cross section. The surface of the body is ...

Embodiment 2

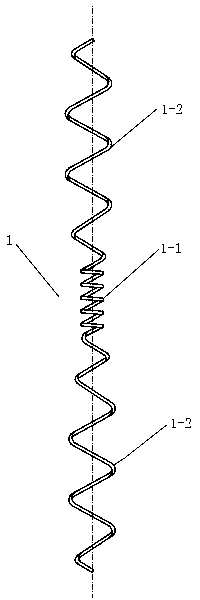

[0022] Example 2: see image 3 A variable-diameter coil spring for removing wax from oil pipes in pumping wells is shown, including a body 1. The body is a coil spring made of elastic wire, which is fitted on the sucker rod 2 in the pumping well, and is connected with the pumping rod 2. Corresponding to the oil pipe 3 in the oil well, the body 1 is composed of a small-diameter section coil spring 1-1 connected with a large-diameter section coil spring 1-2, and the inner diameter of the small-diameter section coil spring 1-1 is slightly smaller than the oil pump The diameter of the rod 2, the outer diameter of the large-diameter segment coil spring 1-2 is slightly smaller than the inner diameter of the oil pipe 3. The middle part of the body 1 is the small-diameter coil spring 1-1, and the two ends are respectively the large-diameter coil spring 1-2. The body 1 is made of elastic wire with a circular cross section. The surface of the body is covered with a chrome-plated lay...

Embodiment 3

[0023] Example 3: see Figure 4 A variable-diameter coil spring for removing wax from oil pipes in pumping wells is shown, including a body 1. The body is a coil spring made of elastic wire, which is fitted on the sucker rod 2 in the pumping well, and is connected with the pumping rod 2. Corresponding to the oil pipe 3 in the oil well, the body 1 is composed of a small-diameter section coil spring 1-1 connected with a large-diameter section coil spring 1-2, and the inner diameter of the small-diameter section coil spring 1-1 is slightly smaller than the oil pump The diameter of the rod 2, the outer diameter of the large-diameter segment coil spring 1-2 is slightly smaller than the inner diameter of the oil pipe 3. The body 1 is composed of two sections of the small-diameter helical spring 1-1 and two sections of the large-diameter helical spring 1-2 connected alternately. The body 1 is made of elastic wire with a circular cross section. The surface of the body is covered w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com