Liquid ring pump

a technology of ring pump and liquid cylinder, which is applied in the direction of pump components, liquid fuel engine components, liquid fuel engines, etc., can solve the problems of negative impact on costs and negatively affect the efficiency of liquid ring pump a

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Many specific details of certain embodiments of the invention are set forth in the detailed description below, and illustrated in enclosed FIGS. 4-10, to provide a thorough understanding of such embodiments. One skilled in the art, however, will understand that the present invention may have additional embodiments, or may be practiced without several of the details described.

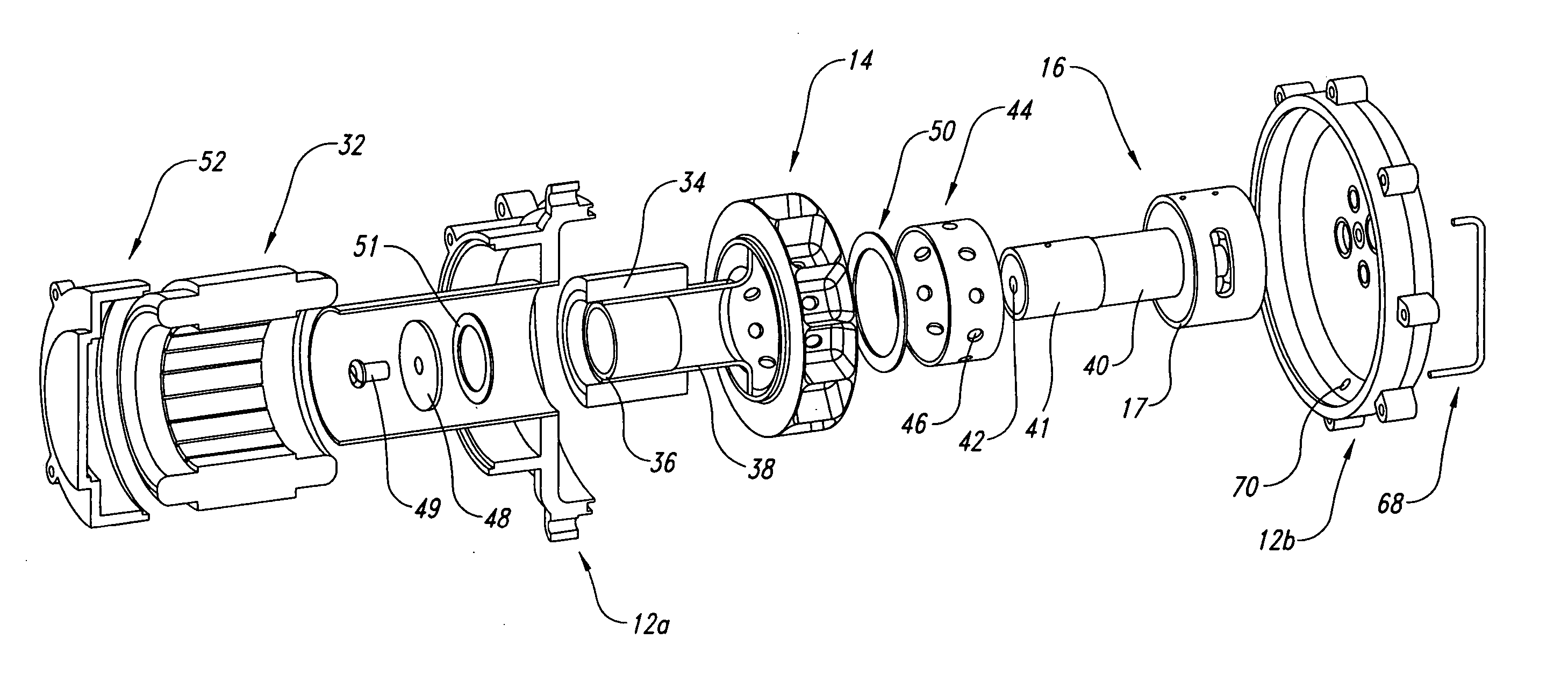

[0034] FIGS. 4 and 5 illustrate a liquid ring pump 10 according to one embodiment of the present invention. Liquid ring pump 10 generally incorporates a housing 12A and 12B (also shown in FIG. 6), an annular rotor 14 (also shown in FIG. 7) and an intake-discharge port assembly 16 (also shown in FIGS. 8A and 8B).

[0035] In the current embodiment, housing 12A / 12B is a 2-part element which, when connected to one another, forms an inner annular surface 18. Rotor 14 is mounted eccentrically within housing 12A / 12B, i.e., axis of rotation e(B) of rotor 14 does not align with geometric center axis c(B) of housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com