Dispenser activation method and apparatus

a technology of activation method and fuel dispenser, which is applied in the direction of liquid transfer device, packaging goods type, liquid handling, etc., can solve the problems of complex and expensive manufacture, installation and repair, and easy failure of fuel dispensers, and achieve the effect of simplifying the operation of the operator, simplifying the operation and avoiding failur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

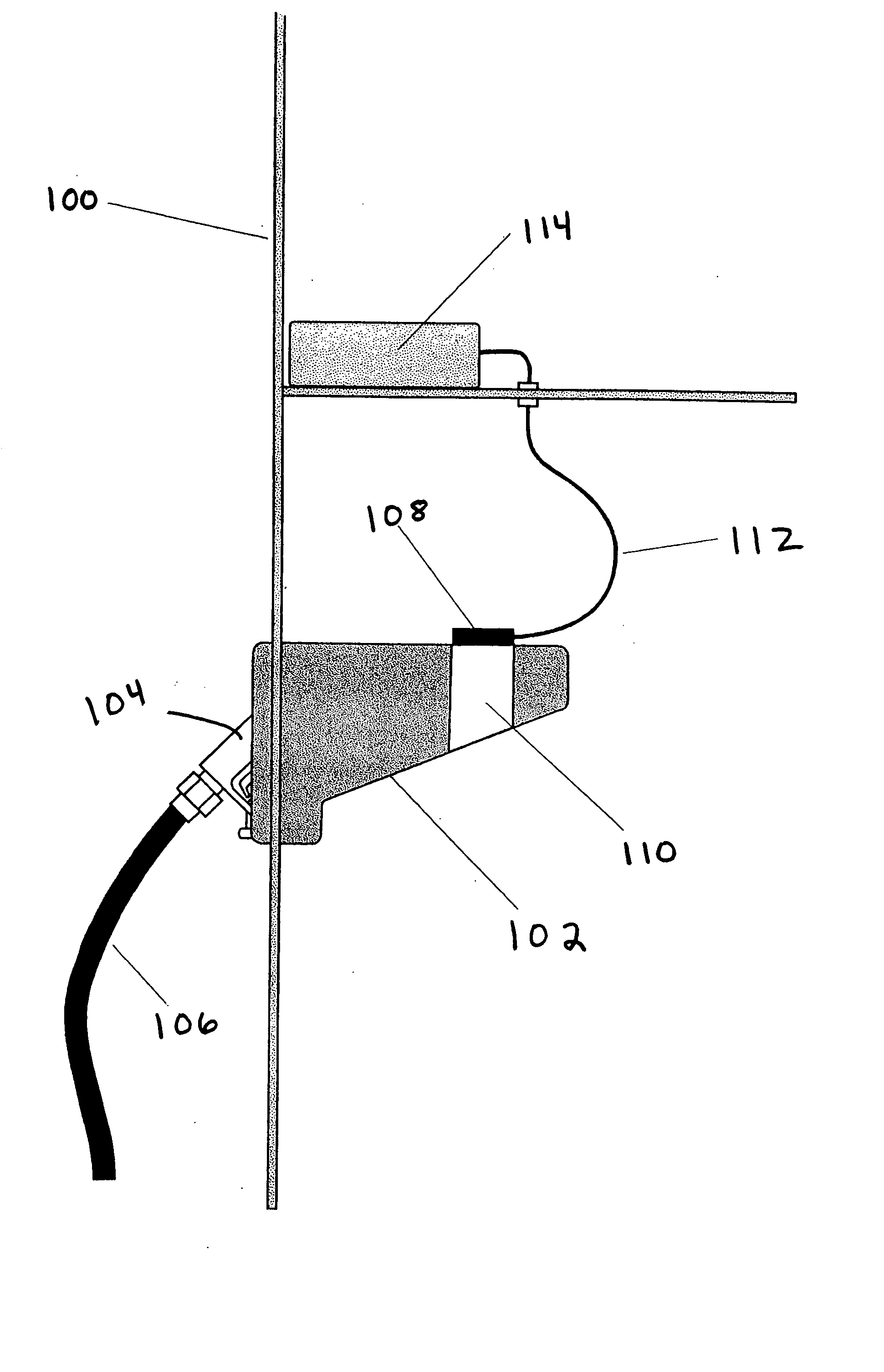

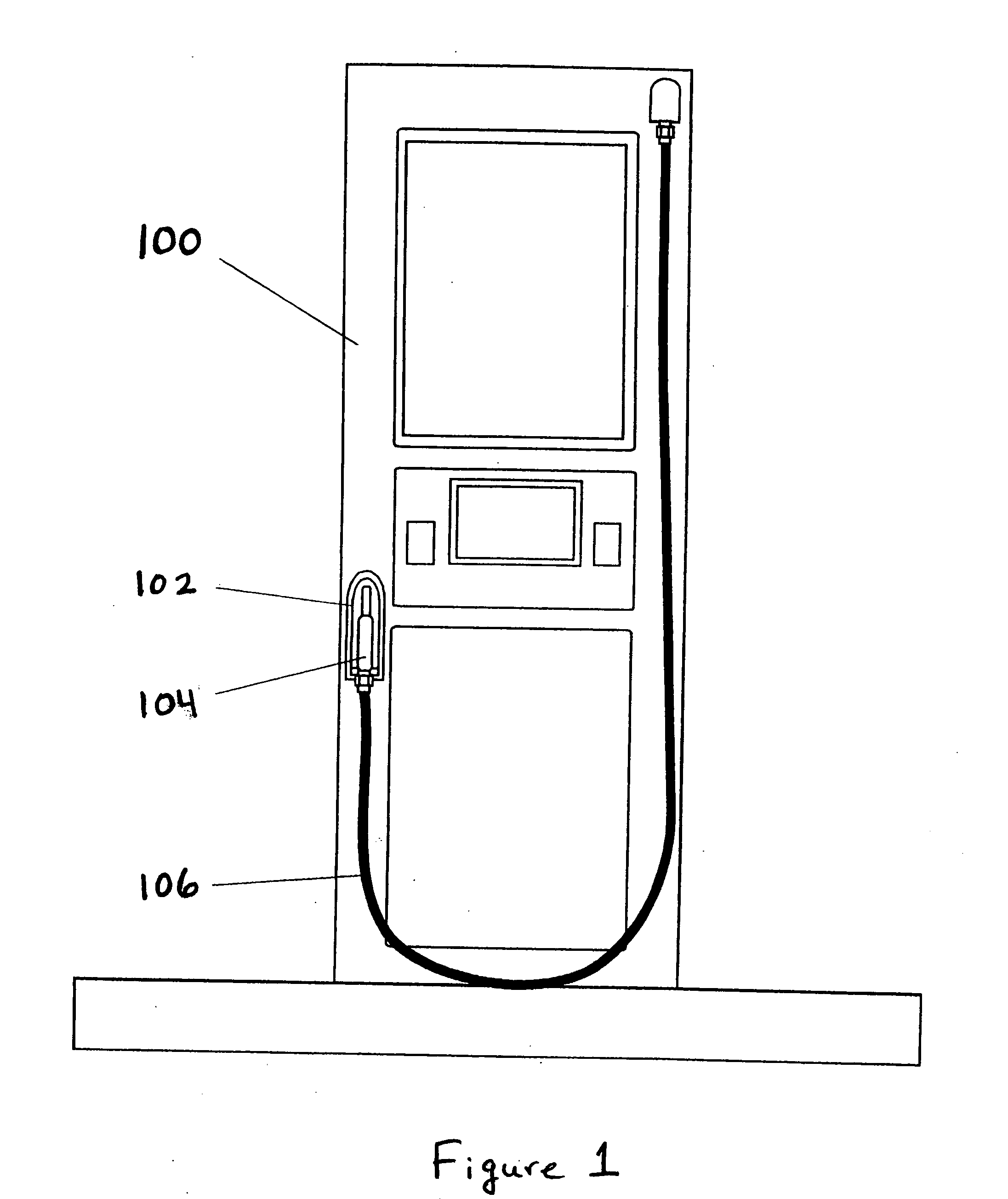

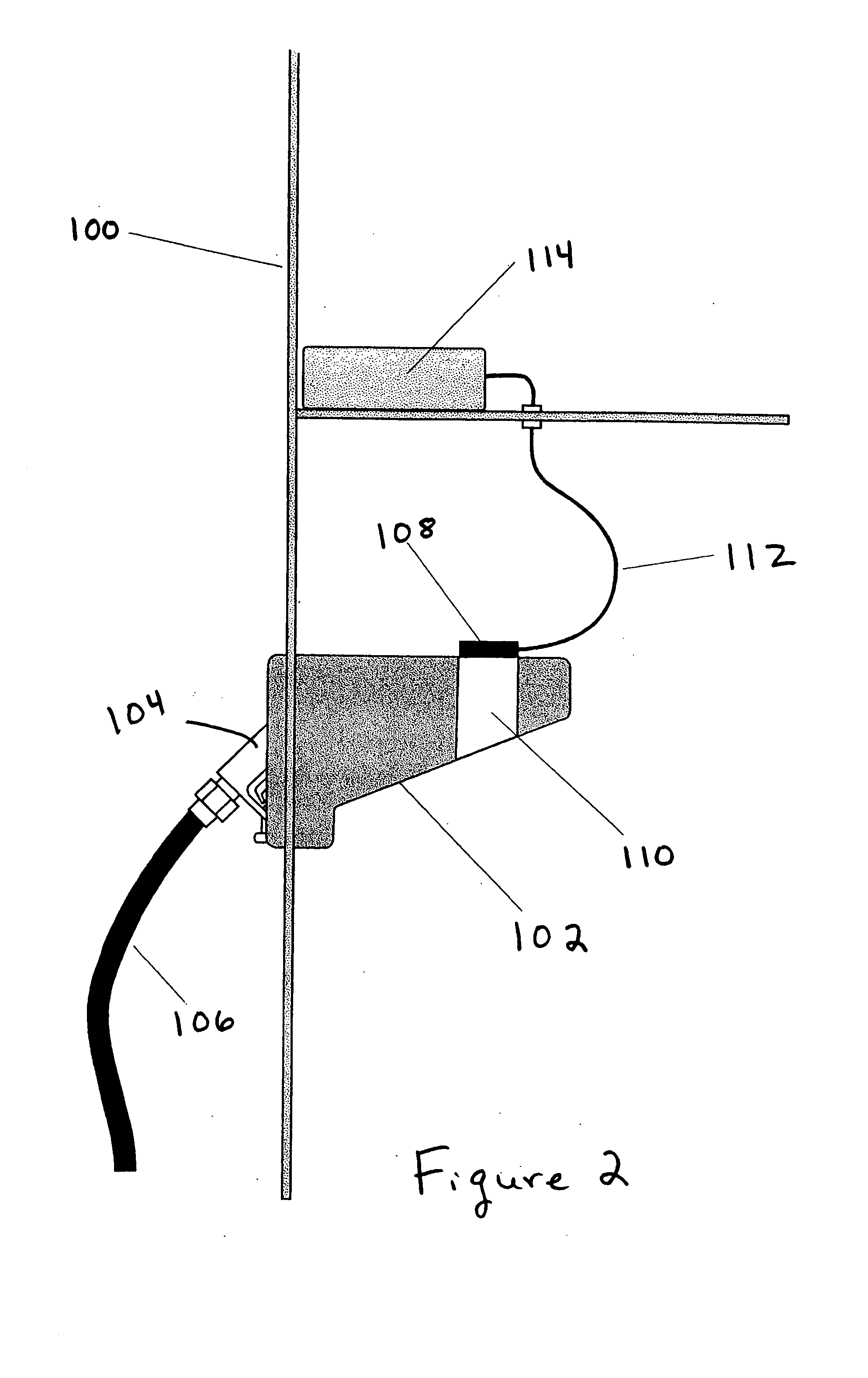

[0019] Referring to the drawings, wherein like reference numerals illustrate corresponding or similar elements throughout the several views, there is shown in FIGS. 1-3 a fuel dispenser 100 according to the present invention. A fueling nozzle 104 is coupled to a fuel source (not shown) via a fueling hose 106. The fueling nozzle 104 may dispense fuel from the fuel source when a fueling transaction is activated and may not dispense fuel when a fueling transaction is terminated.

[0020] The fueling transaction is activated or terminated based on certain factors. Such factors include whether the fueling nozzle 104 is located in or removed from its nozzle boot 102 or holster. When the fueling nozzle 104 is removed from the holster 102, the fuel dispenser 100 may activate the fueling transaction provided that any other requirements or criteria, such as confirmation of payment, are satisfied. When the fueling nozzle 104 is returned to the holster 102, the fuel dispenser 100 terminates the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com