Packaging

a technology of packaging apparatus and toner hopper, which is applied in the field of packaging and packaging apparatus, can solve the problems of excessively difficult design of cushioning that would meet, toner inside the toner hopper may leak to the outside, foul the surrounding environment, etc., and achieve excellent cushioning characteristics and prevent the effect of toner leakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

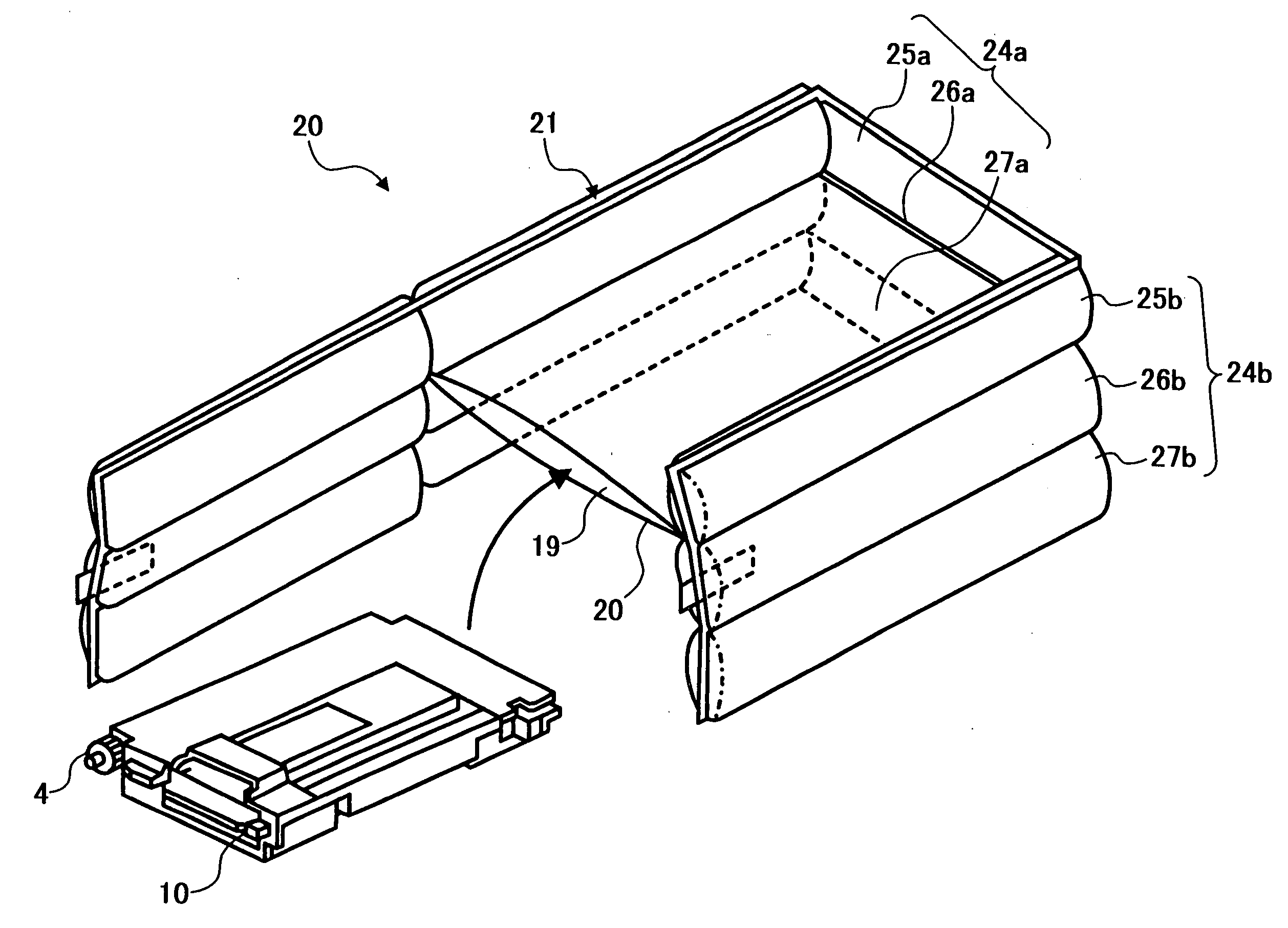

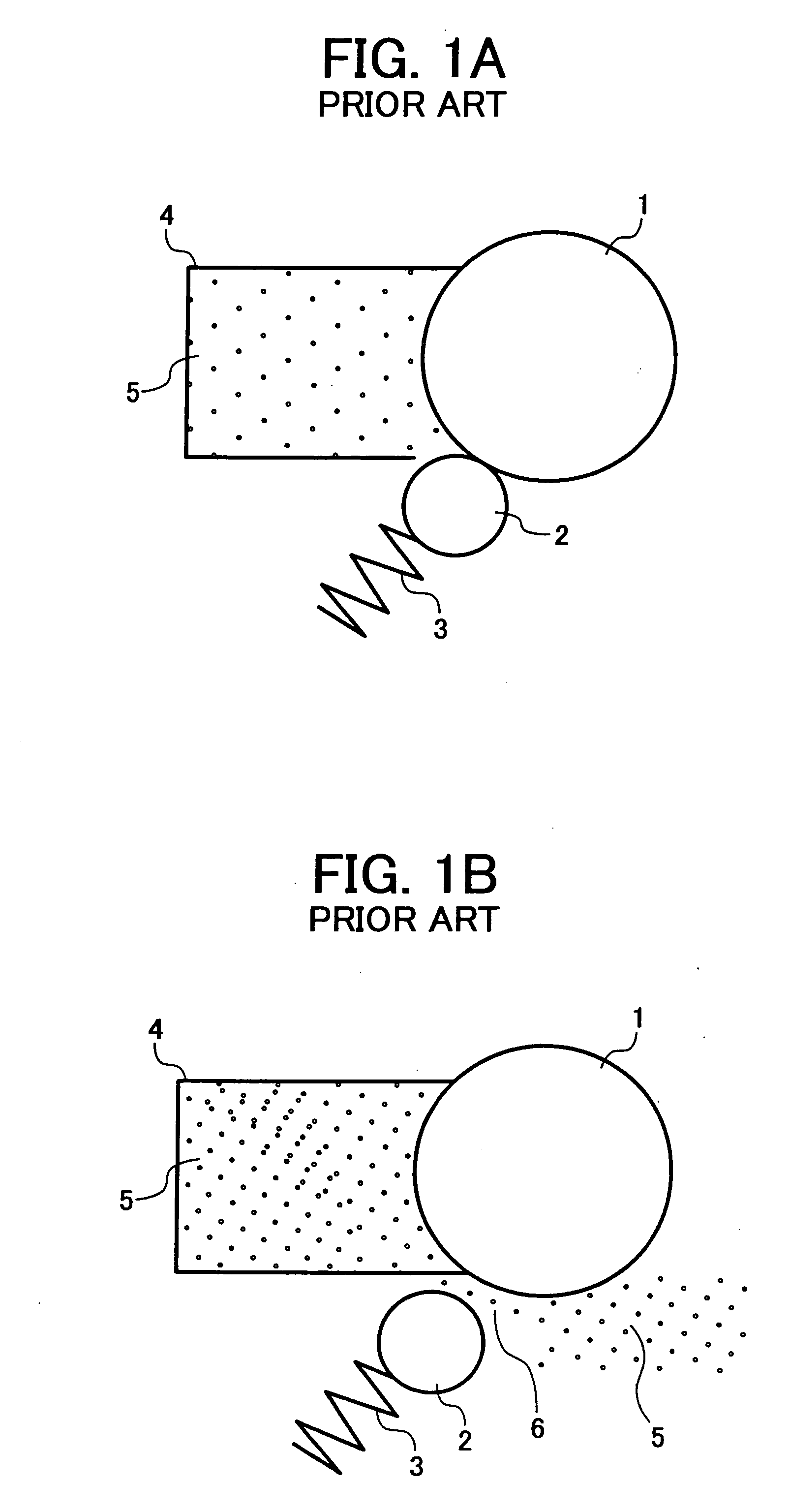

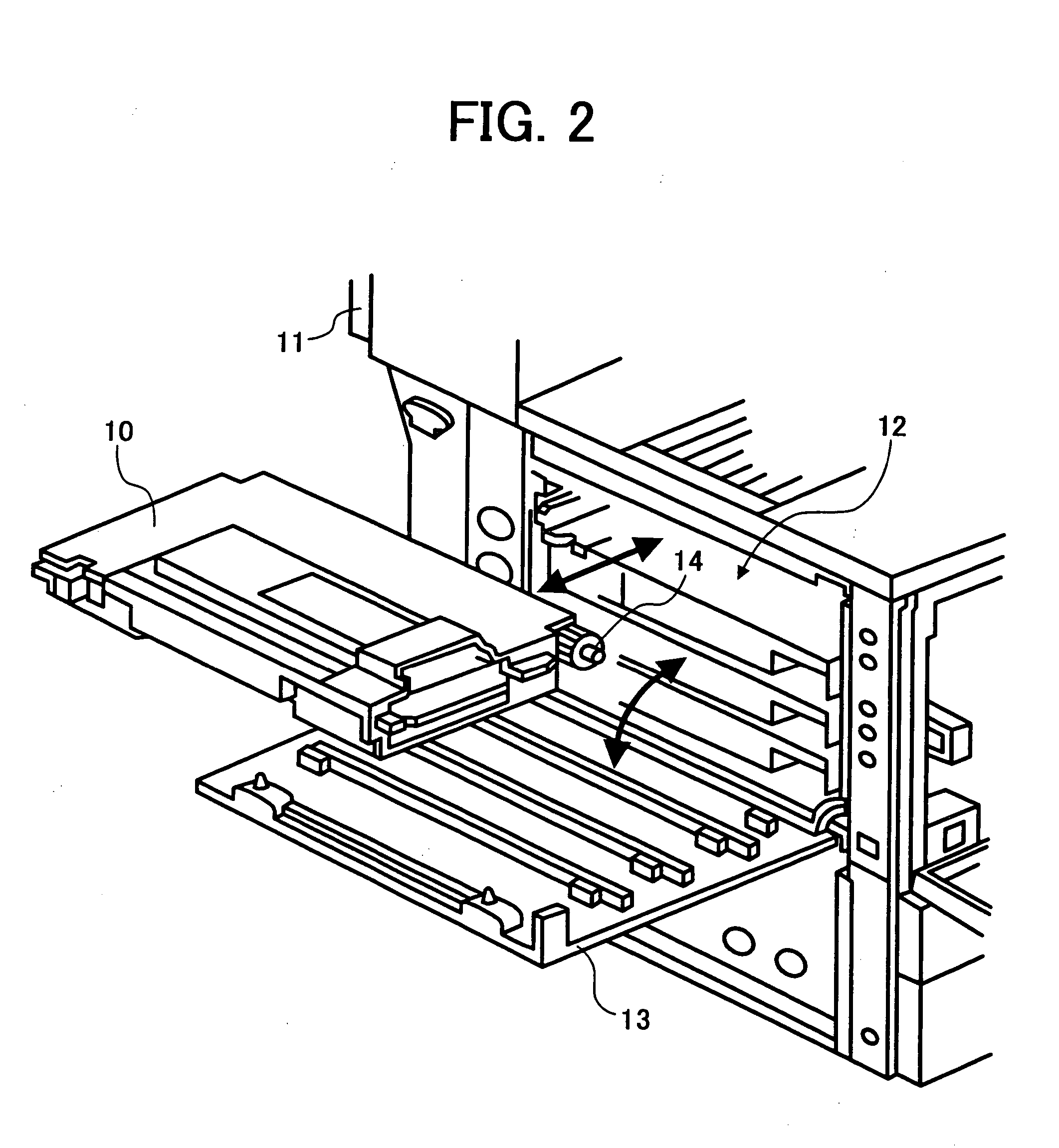

[0017]FIG. 1A shows the structure of the conventional type of process cartridge discussed above, that is, the layout relationship between a developing roller 1, a doctor roller 2, a compression spring 3, and a toner hopper 4 for holding toner 5. As discussed above, whether this process cartridge is conveyed after being loaded into an image forming apparatus, or conveyed separately as a replacement product, if it is subjected to impact, the toner 5 inside the toner hopper 4 may leak to the outside and foul the surrounding environment, so manufacturers generally perform what is call a drop impact test, in which they drop the packaged cartridge from a certain height and inspect it to see if any toner leakage has occurred. Urethane, cardboard, foamed polystyrene, or various other cushioning materials have been employed in the packaging of this conventional process cartridge, but with a process cartridge of this type, if a drop impact test (at a drop of 80 cm, for instance) is performed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com