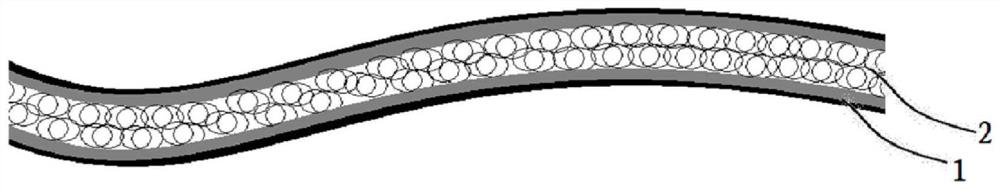

A kind of fiber reinforced motorcycle helmet composite plastic and its preparation method

A composite plastic, fiber-reinforced technology, applied in fiber raw materials, fiber raw material processing, plant fibers, etc., can solve the problems of insufficient impact resistance, low strength, etc., and achieve low cost, simple preparation process, and extensive large-scale promotion and production value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

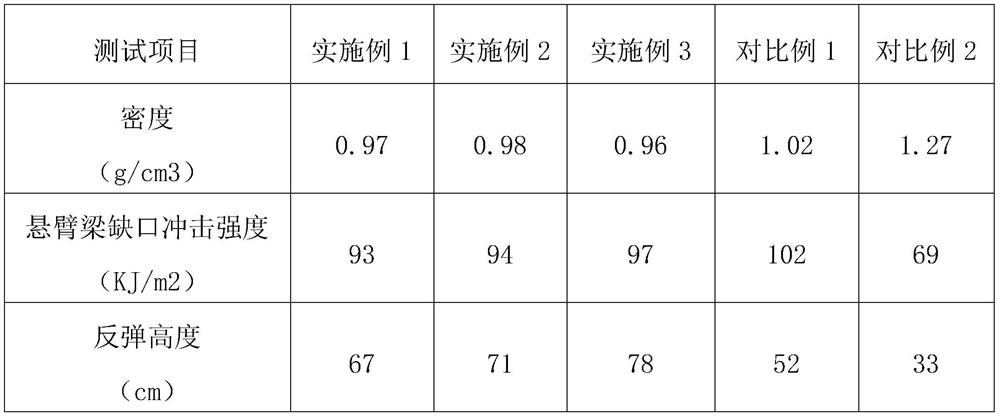

Embodiment 1

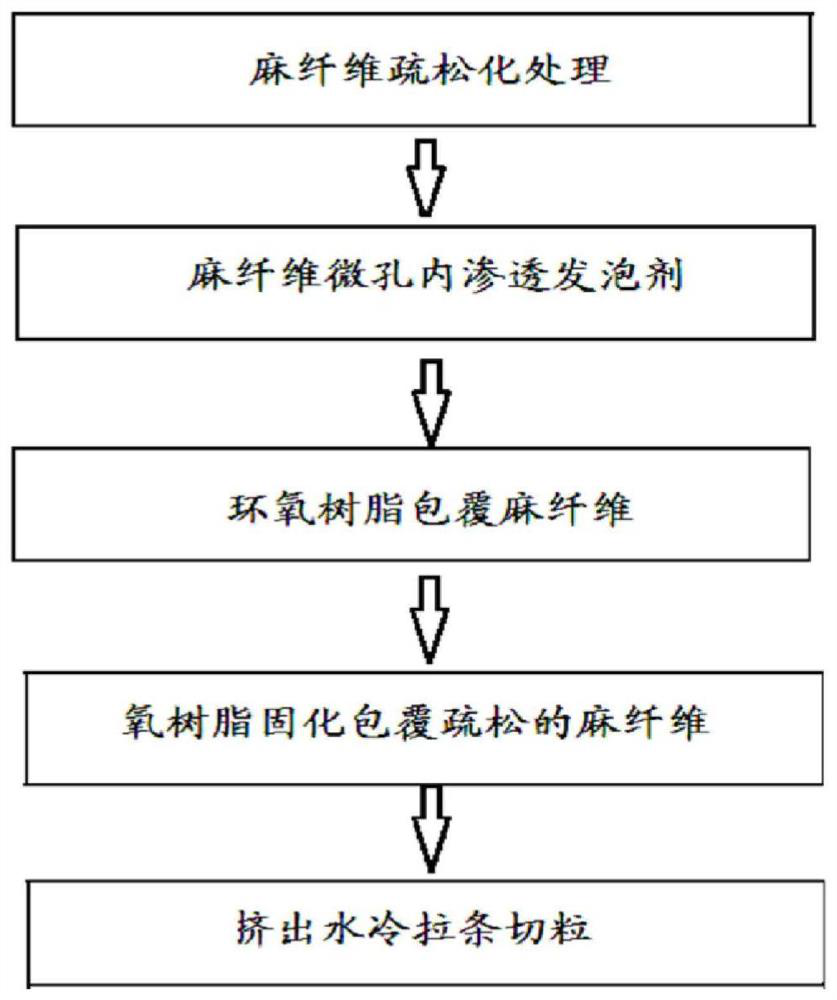

[0035](1) The hemp fiber is cut into fibers of 2-3mm, fully softened by immersion in hot water, then drained, placed in the reaction vessel of the steam explosion device, heated to when the pressure in the reaction vessel rose to 1.0MPa, Hold the pressure for 5 minutes, then quickly release the pressure to loosen the hemp fiber and form micropores, disperse azodicarbonamide and saturated sodium hydroxide lye according to the mass ratio of 1:5 to obtain a foaming liquid, and spray the foaming liquid on the blasting surface For the treated hemp fiber, the amount of foaming solution sprayed is controlled at 5% of the hemp fiber mass, so that the foaming solution fully penetrates the hemp fiber for 1 hour; then dry at 100° C. to obtain pretreated hemp fiber;

[0036] (2) Prepare Miki SM609-50 liquid epoxy resin, pentaerythritol, toluene diisocyanate, and curing agent dicyandiamide in a mass ratio of 40:5:1:3 to prepare a colloidal liquid; add pretreated hemp fiber into a high-speed...

Embodiment 2

[0040] (1) The hemp fiber is cut into fibers of 2-3mm, fully softened by immersion in hot water, then drained, placed in the reaction vessel of the steam explosion device, heated to when the pressure in the reaction vessel rose to 1.0MPa, Hold the pressure for 5 minutes, then quickly release the pressure to loosen the hemp fiber and form micropores, disperse azodicarbonamide and saturated sodium hydroxide lye according to the mass ratio of 1:5 to obtain a foaming liquid, and spray the foaming liquid on the blasting surface For the treated hemp fiber, the amount of foaming solution sprayed is controlled at 3% of the hemp fiber mass, so that the foaming solution fully penetrates the hemp fiber for 1 hour; then dry at 80° C. to obtain pretreated hemp fiber;

[0041] (2) Prepare Miki SM609-50 liquid epoxy resin, pentaerythritol, toluene diisocyanate, and curing agent dicyandiamide in a mass ratio of 40:2:1:3 to prepare a colloidal liquid; add the pretreated hemp fiber into a high-s...

Embodiment 3

[0045] (1) The hemp fiber is cut into fibers of 2-3mm, fully softened by immersion in hot water, then drained, placed in the reaction vessel of the steam explosion device, heated to when the pressure in the reaction vessel rose to 1.5MPa, Hold the pressure for 5 minutes, then quickly release the pressure to loosen the hemp fiber and form micropores, disperse azodicarbonamide and saturated sodium hydroxide lye according to the mass ratio of 1:5 to obtain a foaming liquid, and spray the foaming liquid on the blasting surface For the treated hemp fiber, the spraying amount of the foaming solution is controlled at 3-5% of the quality of the hemp fiber, so that the foaming solution fully penetrates the hemp fiber for 1 hour; then dry at 100° C. to obtain the pretreated hemp fiber;

[0046] (2) Miki SM609-50 liquid epoxy resin, pentaerythritol, toluene diisocyanate, and curing agent dicyandiamide are prepared into a gelatinous liquid with a mass ratio of 50:5:2:3; the pretreated hemp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com