A kind of self-cleaning filter cloth and preparation method thereof

A filter cloth and self-cleaning technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems that the micropores of the fabric are easily blocked by fine particles and dust, high filtration resistance, low efficiency, etc., and achieve good Self-cleaning, ensuring microporosity, and solving the effect of coating peeling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

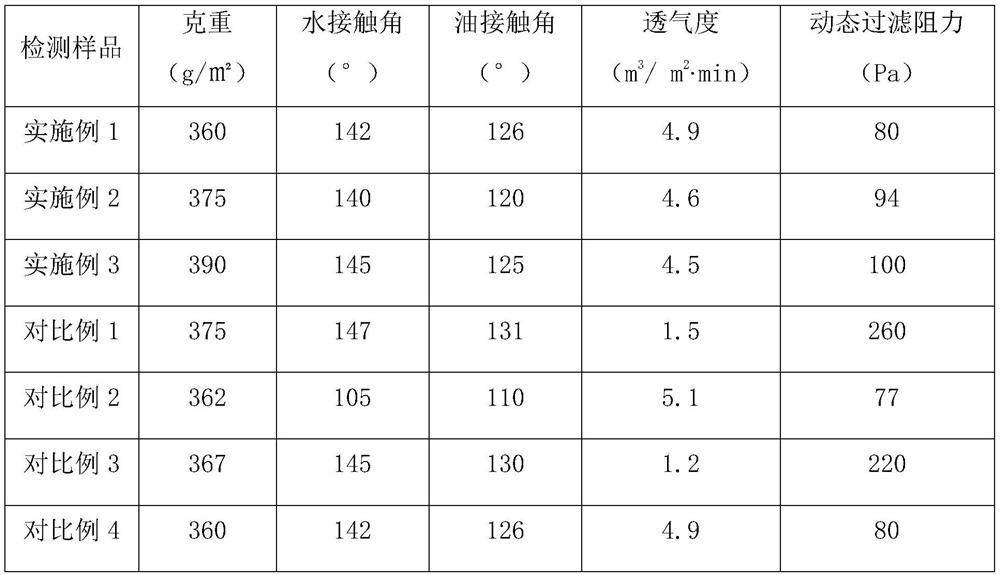

Embodiment 1

[0032] (1) Sodium bicarbonate is prepared as a solution that has a mass concentration of 8%, and it is packed into an infiltration tank, then 30 polyamide fiber fibers are twisted by Z through the infiltration tank, and the sodium bicarbonate solution is adsorbed, and excess sodium bicarbonate solution is removed by pressure filtration, spare;

[0033] (2) adding alum to a high-concentration polytetrafluoroethylene aqueous phase dispersion (commercially available model is FR301B) with a solid content of 60wt% to disperse evenly to obtain a coating solution, dipping 30 composite fibers of S twist into the coating solution; alum The addition amount of the polytetrafluoroethylene emulsion is 5% of the quality of the polytetrafluoroethylene emulsion; the composite fiber is a composite twisted fiber yarn of alumina fiber and nylon fiber, and the proportion of alumina fiber is 20%;

[0034] (3) the Z-twisted nylon fiber pretreated in step (1) and the S-twisted composite fiber pretre...

Embodiment 2

[0038] (1) Sodium bicarbonate is prepared as a mass concentration of 8% solution, put into the soaking tank, then 40 polyamide fibers are twisted by Z through the soaking tank, absorb the sodium bicarbonate solution, press filter to remove excess sodium bicarbonate solution, spare;

[0039] (2) Alum is added into the high-concentration polytetrafluoroethylene aqueous phase dispersion liquid (commercially available model is FR301B) that solid content is 60wt% to disperse evenly to obtain coating liquid, 40 composite fibers of S twist are dip-coated coating liquid; Alum The addition amount of the polytetrafluoroethylene emulsion is 3% of the quality of the polytetrafluoroethylene emulsion; the composite fiber is a composite twisted fiber yarn of alumina fiber and nylon fiber, and the proportion of alumina fiber is 20%;

[0040] (3) the Z-twisted nylon fiber pretreated in step (1) and the S-twisted composite fiber pretreated in step (2) are plied according to the Z-twisted mode t...

Embodiment 3

[0044] (1) Sodium bicarbonate is prepared as a mass concentration of 8% solution, put into the soaking tank, then 50 polyamide fibers are twisted by Z through the soaking tank, absorb the sodium bicarbonate solution, press filter to remove excess sodium bicarbonate solution, spare;

[0045] (2) adding alum to the high-concentration polytetrafluoroethylene aqueous phase dispersion liquid (commercially available model is FR301B) that solid content is 60wt% disperses evenly to obtain the coating liquid, dip-coating the coating liquid with 50 composite fibers of S twist; alum The addition amount of the polytetrafluoroethylene emulsion is 5% of the quality of the polytetrafluoroethylene emulsion; the composite fiber is a composite twisted fiber yarn of alumina fiber and nylon fiber, and the proportion of alumina fiber is 15%;

[0046] (3) the Z-twisted nylon fiber pretreated in step (1) and the S-twisted composite fiber pretreated in step (2) are plied according to the Z-twisted mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com