Chlorosulfonated polyethylene microporous foam material and method for preparing same

A technology of chlorosulfonated polyethylene and microcellular foamed material, applied in the field of polymer materials, can solve the problem of high cost and achieve the effects of good electrical insulation, excellent chemical resistance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

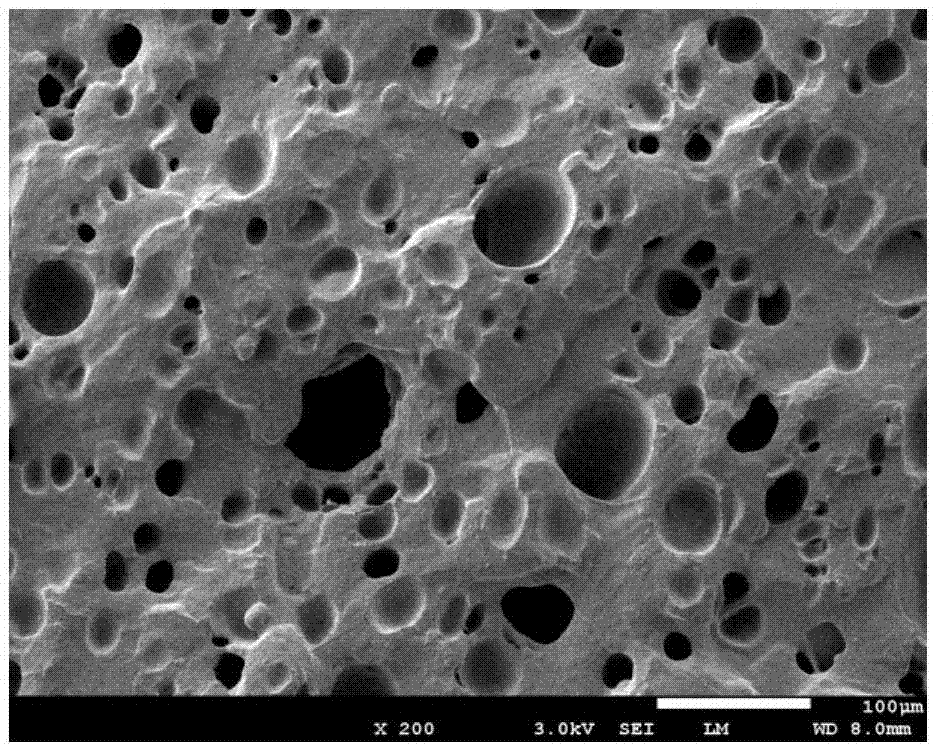

Embodiment 1

[0033] 100 parts of chlorosulfonated polyethylene, 2 parts of stabilizer, 10 parts of filler, 1 part of anti-aging agent, 4 parts of vulcanizing agent, 6 parts of accelerator.

[0034] The filler is carbon black; the anti-aging agent is 4010NA; the vulcanizing agent is high-activity magnesium oxide; the vulcanization accelerator is pentaerythritol, TAIC, and DPTT.

[0035] Weigh the various raw materials in the formula according to the required weight and put them into the internal mixer. The temperature of the internal mixer is 90 ° C, and the mixing time is 5 minutes. . After that, put the mixed rubber into the sheet in the open mill, and then use a flat vulcanizer to pre-vulcanize the film at 140°C for 5 minutes, then take out the sample sheet and put it into the foaming device. The temperature of the device is set at 130°C, and CO 2 Gas to a pressure of 16Mpa, take it out after being saturated for 1 hour, then perform secondary vulcanization in an oven at 170°C for 20 min...

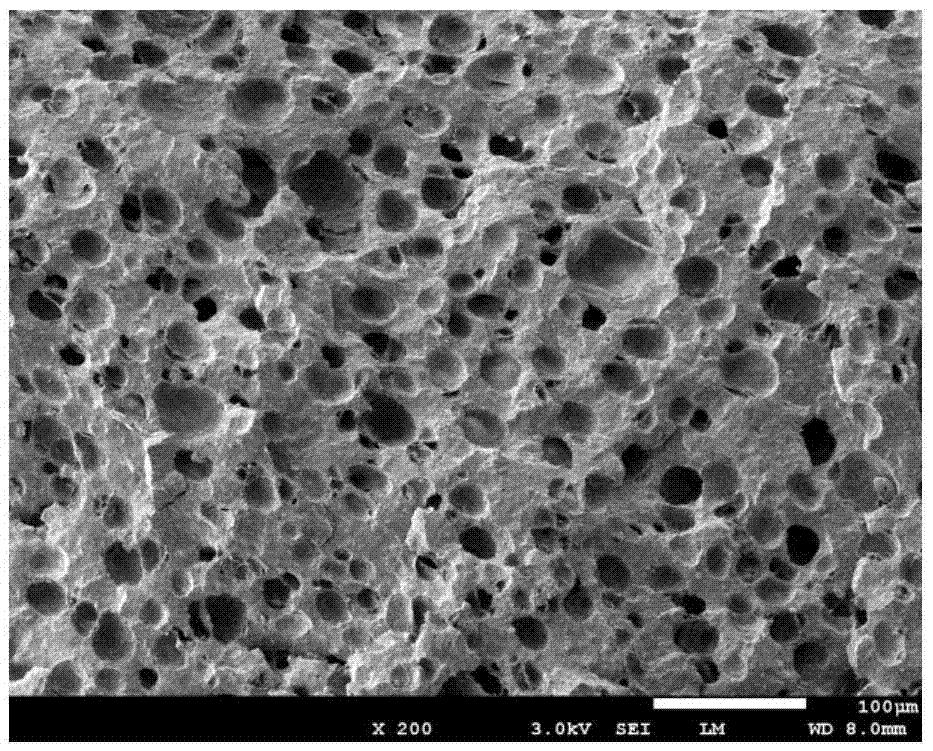

Embodiment 2

[0037] 100 parts of chlorosulfonated polyethylene, 2 parts of stabilizer, 20 parts of filler, 1 part of anti-aging agent, 4 parts of vulcanizing agent, 6 parts of accelerator.

[0038] The filler is kaolin, 1250 mesh; the anti-aging agent is 4010NA; the vulcanizing agent is high-activity magnesium oxide;

[0039] The vulcanization accelerator is combined use of pentaerythritol, TAIC, and DPTT.

[0040] Weigh the various raw materials in the formula according to the required weight and put them into the internal mixer. The temperature of the internal mixer is 90 ° C, and the mixing time is 5 minutes. . Afterwards, the mixed rubber is unloaded in the open mill, and then the film is pre-vulcanized at 130°C for 10 minutes with a flat vulcanizer, and then the sample piece is taken out and placed in a foaming device. The temperature of the device is set at 140°C, and CO is introduced. 2 Gas to a pressure of 16Mpa, take it out after 2 hours of saturation, and then perform secondary...

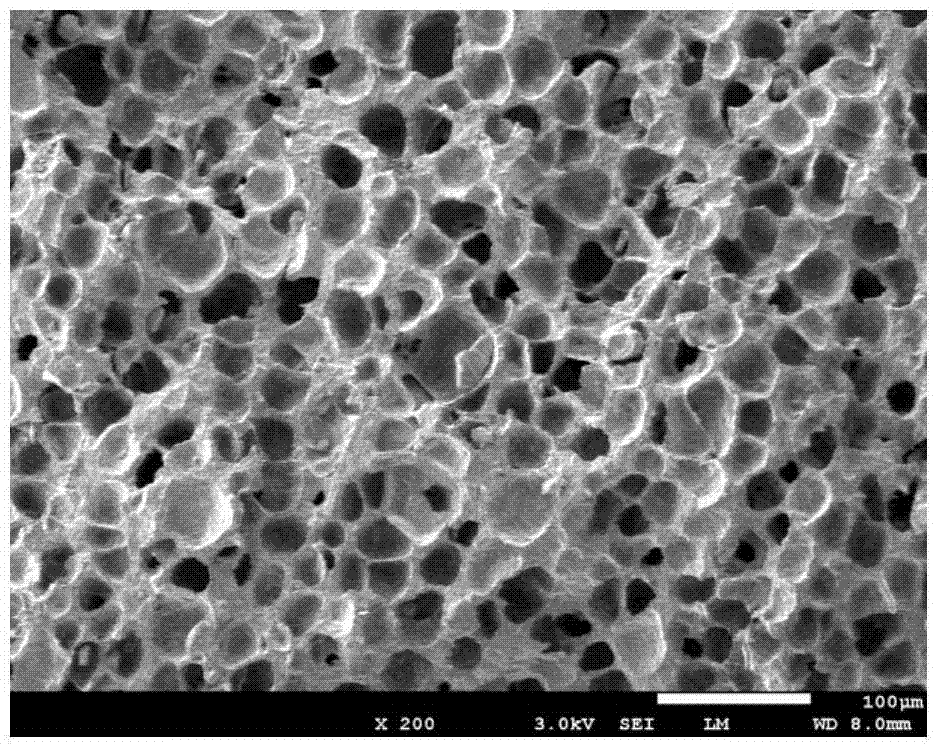

Embodiment 3

[0042] 100 parts of chlorosulfonated polyethylene, 2 parts of stabilizer, 15 parts of filler, 2 parts of plasticizer, 1 part of anti-aging agent, 3.3 parts of vulcanizing agent, 5.5 parts of accelerator.

[0043] The filler is white carbon black; the plasticizer is DIOA; the anti-aging agent is anti-aging agent 2246; the vulcanizing agent is high-activity magnesium oxide; the vulcanization accelerator is pentaerythritol, TAIC, and ZnO used together.

[0044] Weigh the various raw materials in the formula according to the required weight and put them into the internal mixer. The temperature of the internal mixer is 100°C, and the mixing time is 7 minutes. . After that, put the mixed rubber into the sheet in the open mill, and then pre-vulcanize the sheet with a flat vulcanizer at 150°C for 12 minutes, then take out the sample sheet and put it into the foaming device. The temperature of the device is set at room temperature, and N 2 Gas to a pressure of 16Mpa, take it out after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com