In-mold labeling method and labeled products

a labeling method and label technology, applied in the field of in-mold labeling and labeling molded products, can solve the problems of unattractive appearance of articles, damage to adhesively secured labels, and inability to meet the requirements of in-mold labeling procedures,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

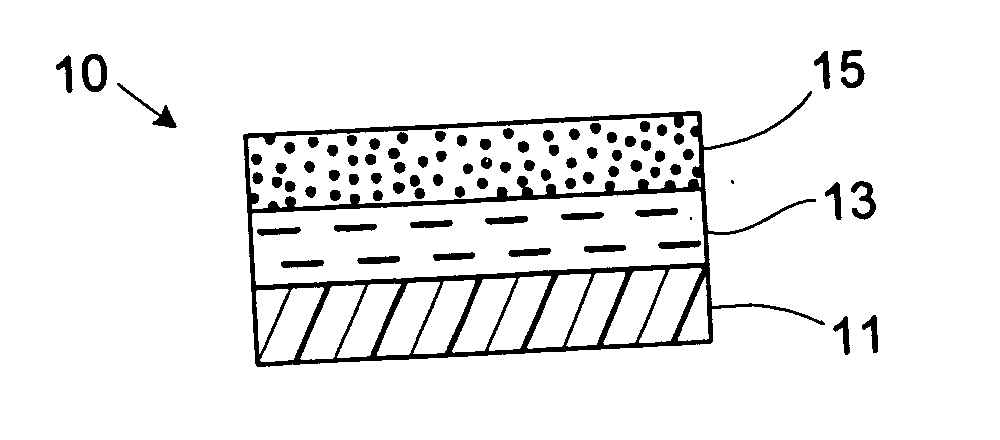

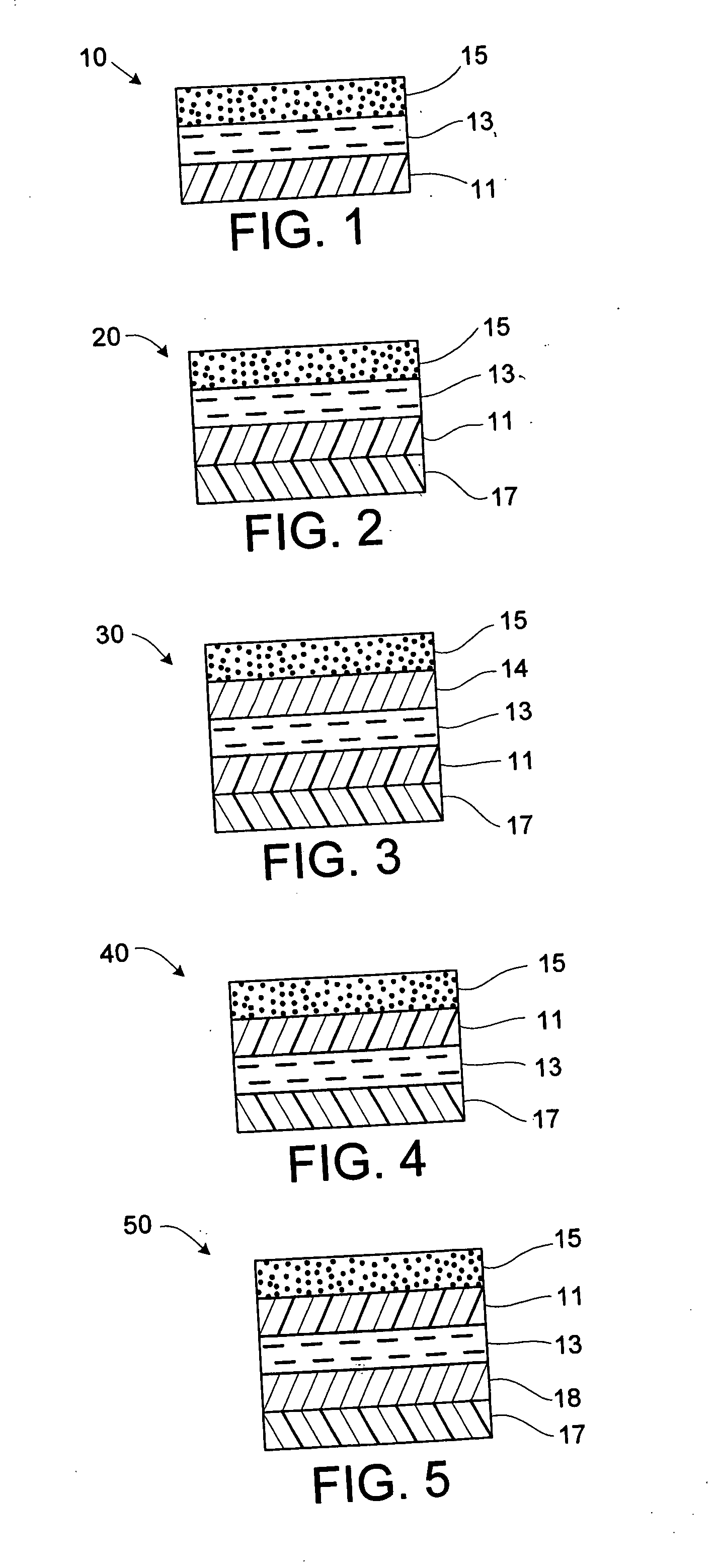

Image

Examples

example i

This example illustrates the preparation of a white, surface-printed in-mold label film. The facestock utilized in this example is a white opaque clay modified polypropylene film available from HOP Industries. The film thickness is about 7.5 mil. The upper surface of the facestock is corona treated, and an ink adhesion promoting layer is applied to the corona treated surface at a coating weight of about 1.1 g / m2 of the facestock via an anilox roll. The adhesion promoting material is CLBO-4275 F-Prokote Primer (a product of Sun Chemical Corp. identified as a solvent based primer). The adhesion promoting material is cured in an oven at a temperature of 40-50° C.

A multi-colored ink or print layer providing a pictorial design in combination with a printed message is applied over the adhesion promoting layer. The print layer is applied using a sequence of three anilox rolls. The following inks are used: Roll 1: Yellow 116 ink (a UV curable ink provided by Daw Ink) Roll 2: Red 186 in...

example ii

This example illustrates the preparation of a clear, sub-surface printed label film construction. A clear polymer facestock film identified as Fasclear which is available from Avery Dennison Engineered Films Division, Avery Dennison Corp. is utilized in this example. The film has a thickness of about 6 mils. The lower surface of the facestock film is corona treated, and an ink adhesion promoting layer is applied (1.1 g / m2) to the corona treated lower surface of the facestock via an anilox roll. The adhesion promoting material is CLBO-4275 F-Prokote Primer. The adhesion promoting material is cured in an oven at a temperature of 40-50° C.

A multicolored ink or graphics print layer providing a pictorial design in combination with a printed message is applied under the adhesion promoting layer. The ink or graphics print layer is applied using a sequence of three anilox rolls. The inks used in this example are the same as used in Example I. Each ink application is UV cured prior to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion strength | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

| Transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com