Window flashing assembly

a technology for windows and windows, applied in the field of building materials, can solve the problems of uneconomic use of doors and windows, seal failure, etc., and achieve the effects of minimizing material failure or installation error, maximizing sealing performance, and minimizing the number of components required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is a window flashing assembly that provides an improved barrier to moisture.

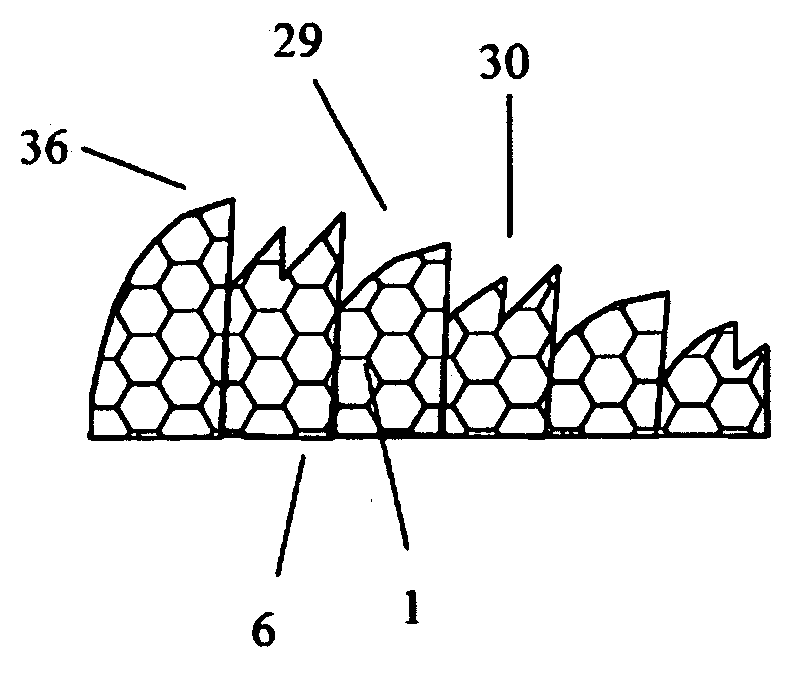

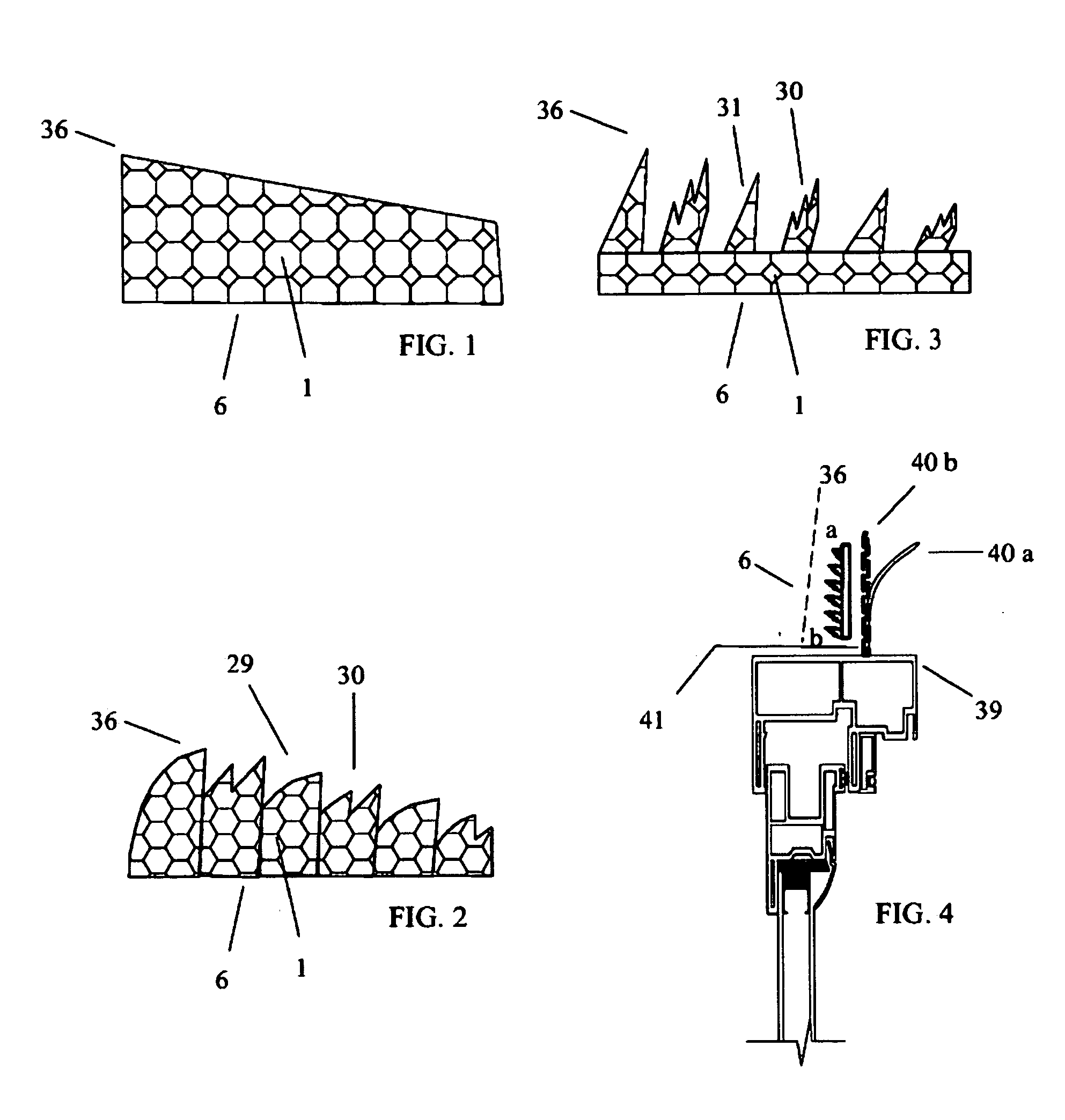

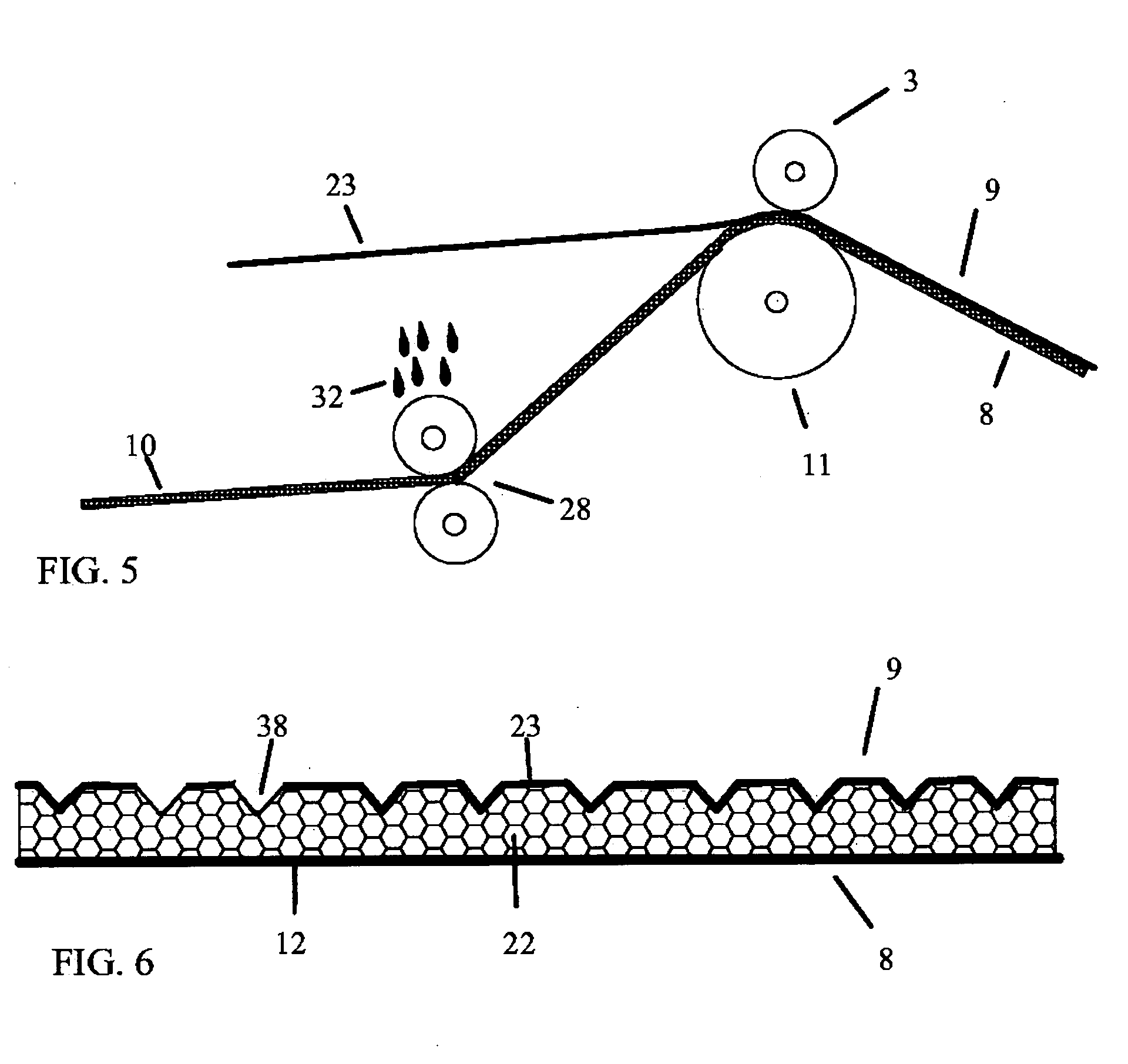

[0044]FIG. 1 demonstrates a cross section of the under flange seal 6 from closed cell foam 1 that is formed at a width approximate to the width of a window nailing flange and is tapered 36 from one side to the other. As is demonstrated in FIG. 4 it is essential that the seal tapers to correspond with the compression strength of the nailing flange to avoid excessive flange deflection. In addition to stressing the flange, contrary to industry and manufacture standards, the flange elevation away from wall sheathing makes installation of trim around the window difficult. Current flashing systems rely on caulk to seal the window to the flashing membrane. Sealing caulks currently in use have a cure time varying from a few days to a few weeks. Testing shows that when these caulks are placed between materials having a low perm rating such as many flashing membranes and a window flange c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com