Novel enzymes which dehydrate glycerol

a technology of glycerol and enzymes, which is applied in the field of new enzymes which dehydrate glycerol, thermophil, etc., can solve the problems of high cost of traditional chemical synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

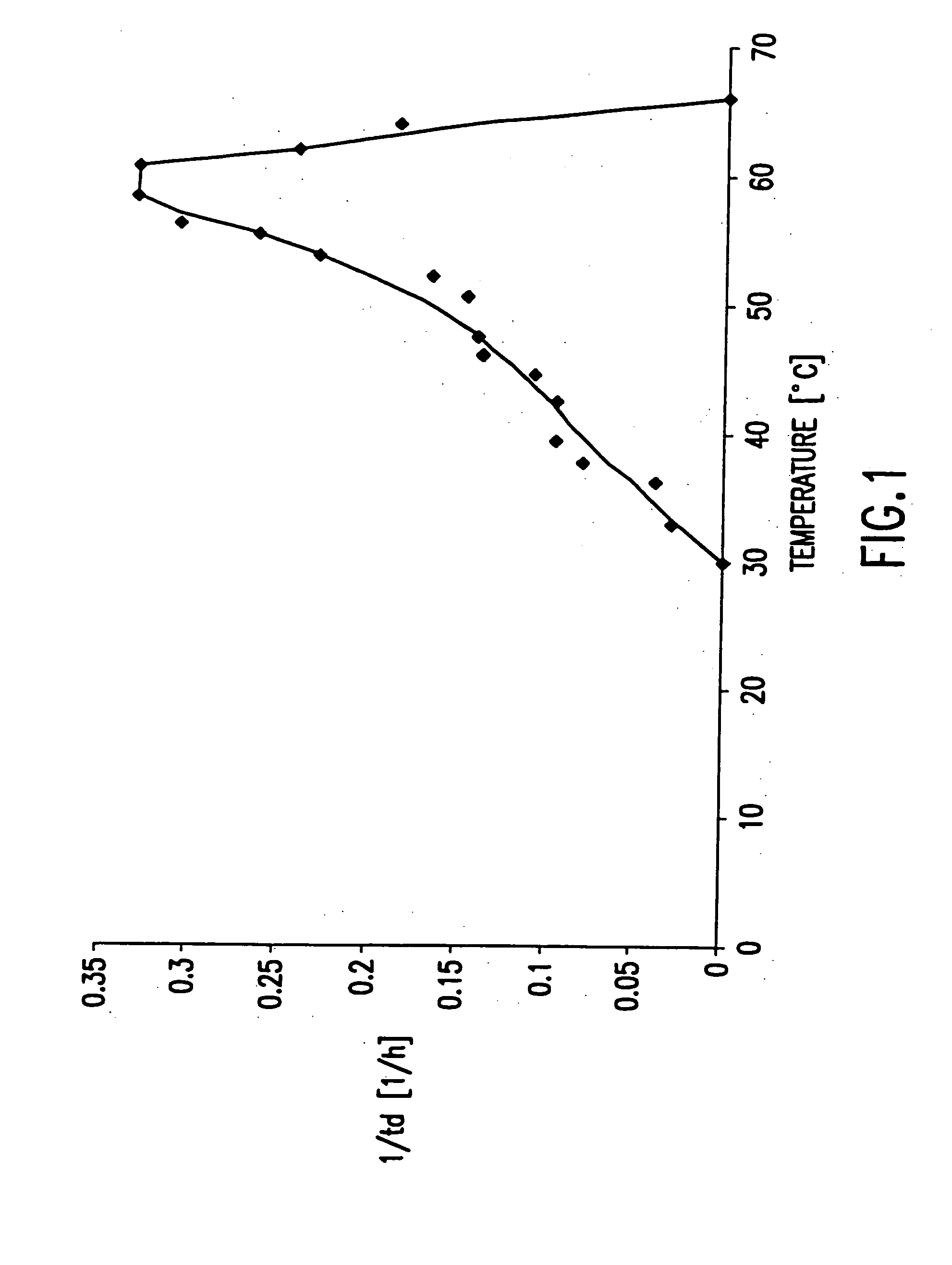

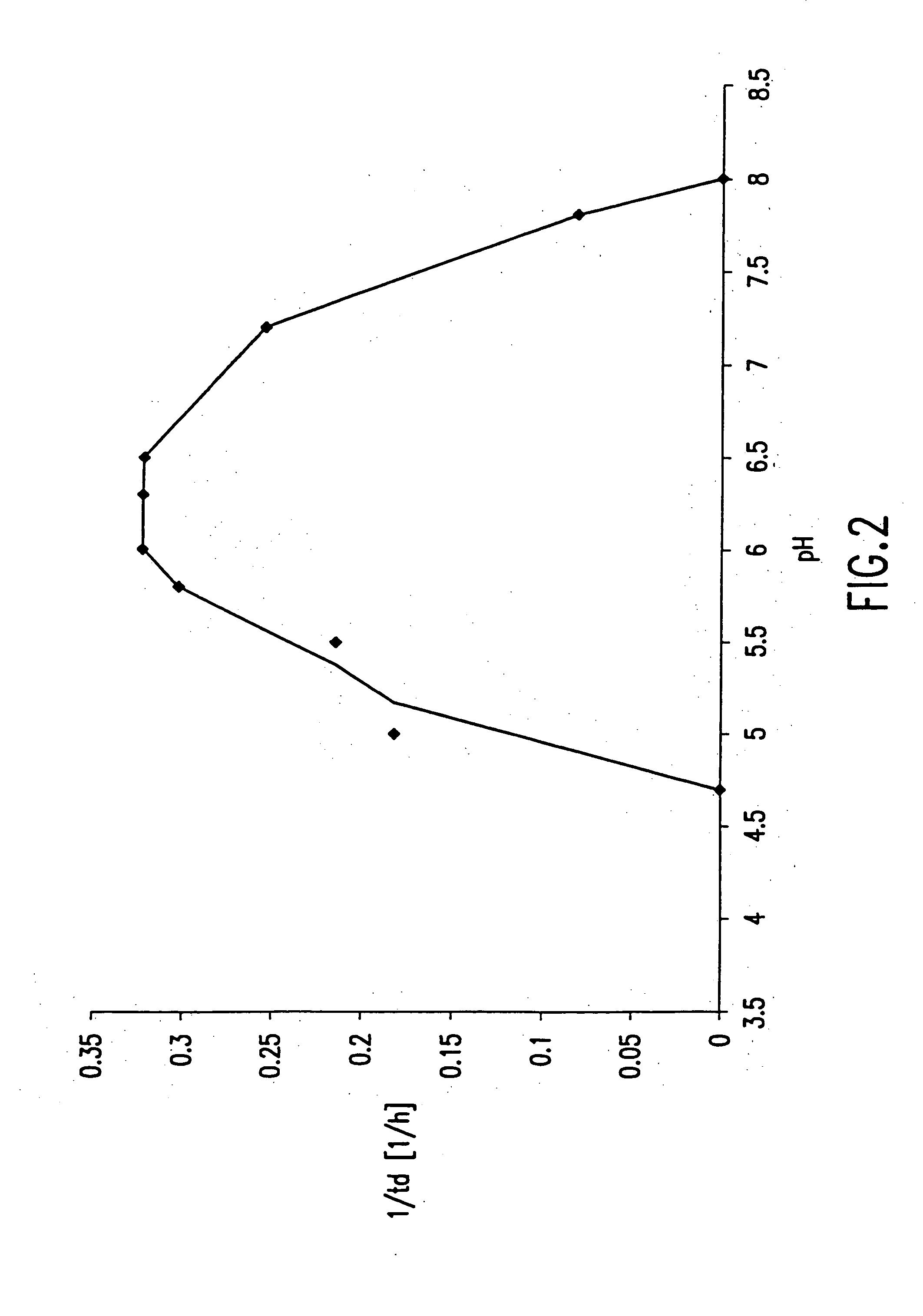

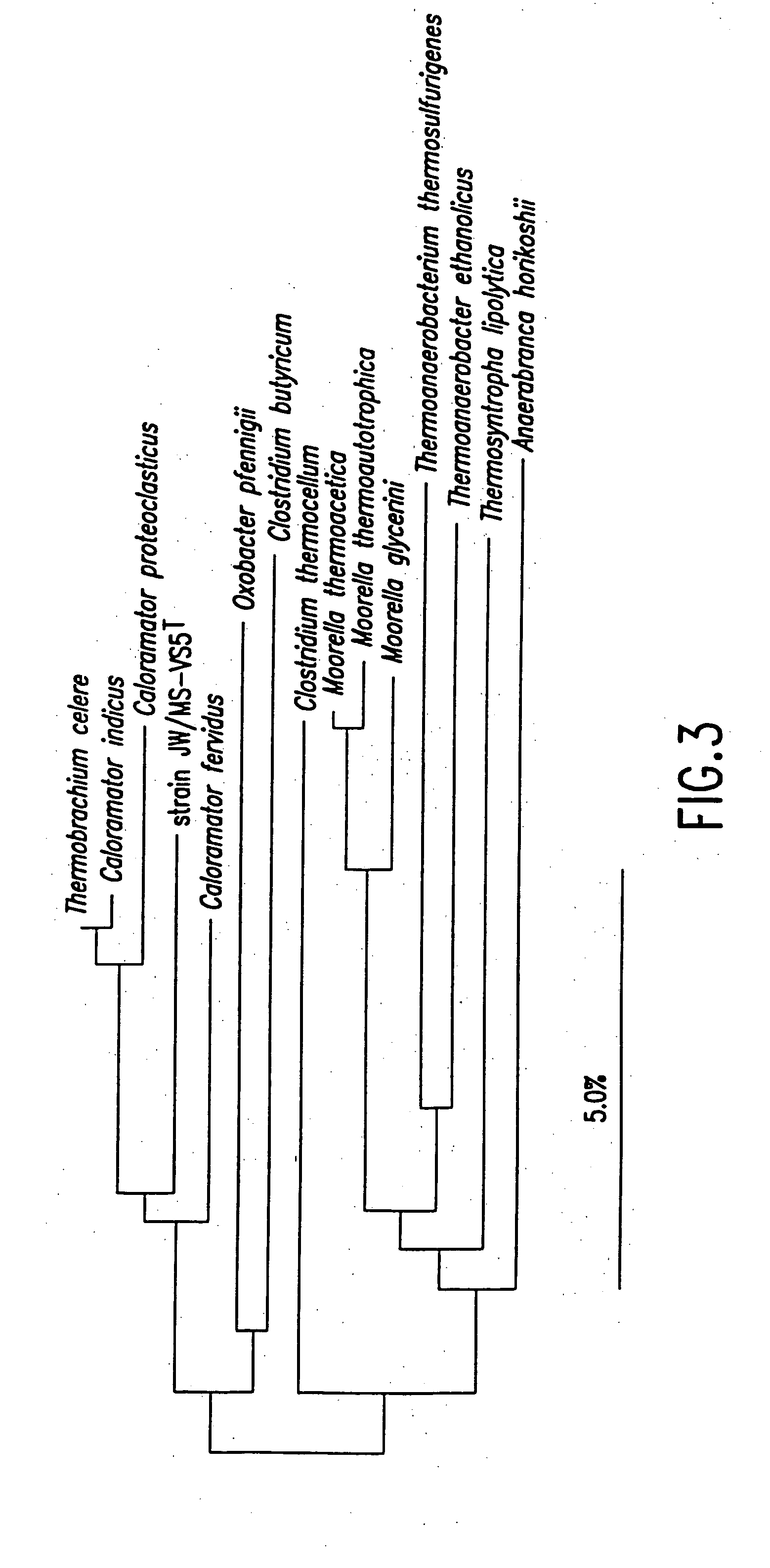

Thermophilic organisms are organisms that can survive and grow at elevated temperatures where most other organisms (e.g., mesophiles) would not be able to survive. This unusual resilience towards high temperatures results in part from these organisms' use of thermostable enzymes to catalyze the biological reactions of life. Thermostable enzymes allow thermophilic organisms to catalyze metabolic reactions at elevated temperatures. Such organisms can be isolated from ambient temperature environments, but are more likely isolated from high temperature environments including, for example, hot springs, thermal vents and laundromat effluents. The unusual thermostability of thermophilic bacteria and enzymes allows one to catalyze economically valuable bioconversions at higher temperatures than could be achieved using mesophilic organisms and enzymes. In many cases, thermophilic bacteria are used to catalyze the desired reaction in vivo in a fermentation process. Alternatively, thermostabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thermostable | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com