Broom, method, and broom display

a technology of brooms and brooms, applied in the field of brooms, methods can solve the problems of brooms slipping between hanging rods, brooms being attached to brooms, and broom displays becoming unsightly, and achieve excellent utility and amenability to being displayed, and made very inexpensively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

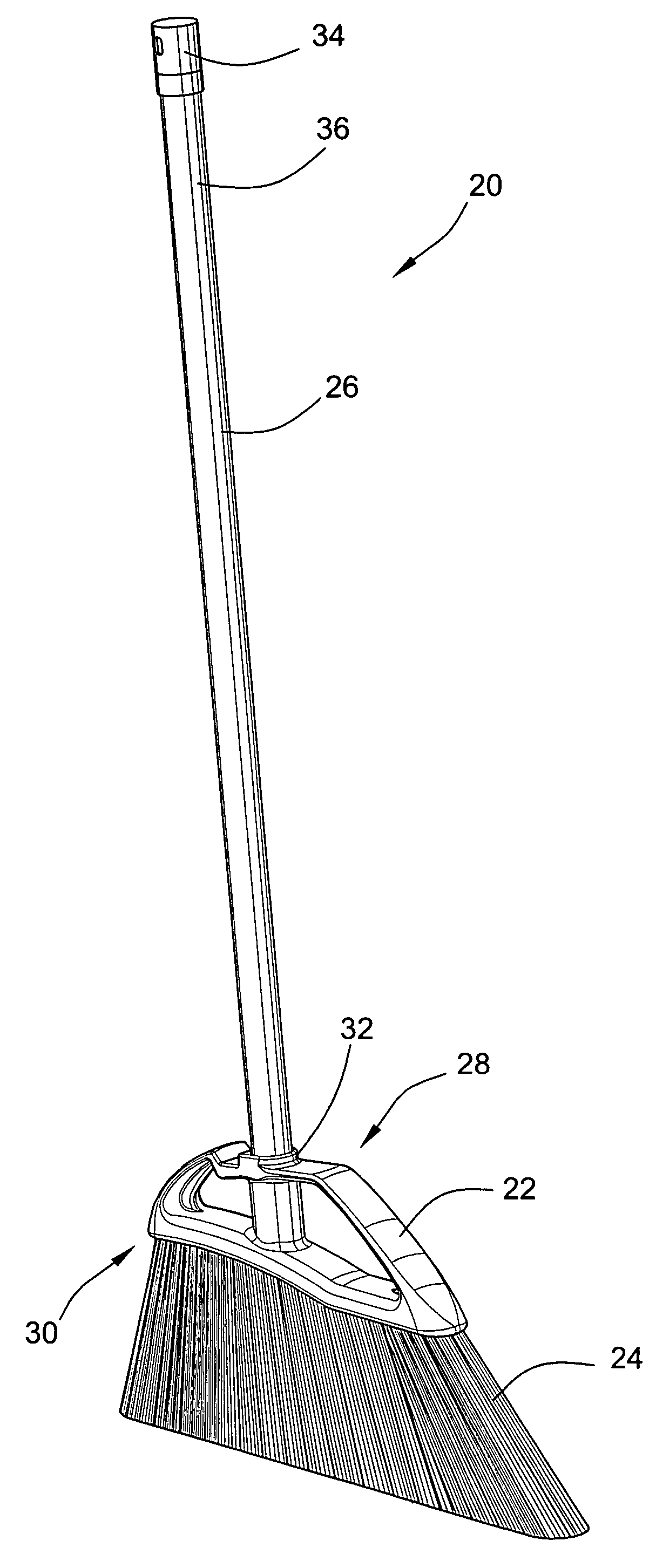

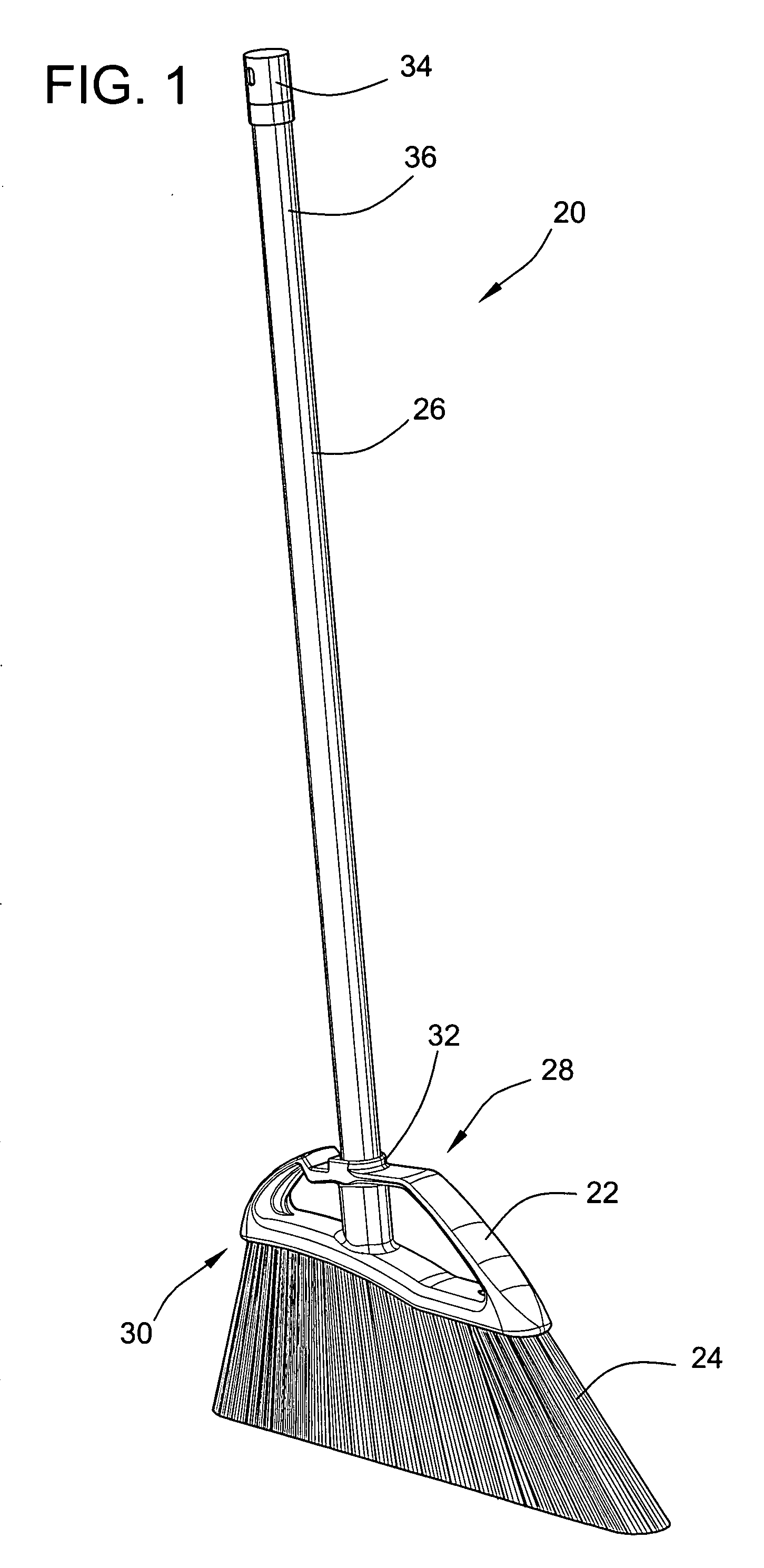

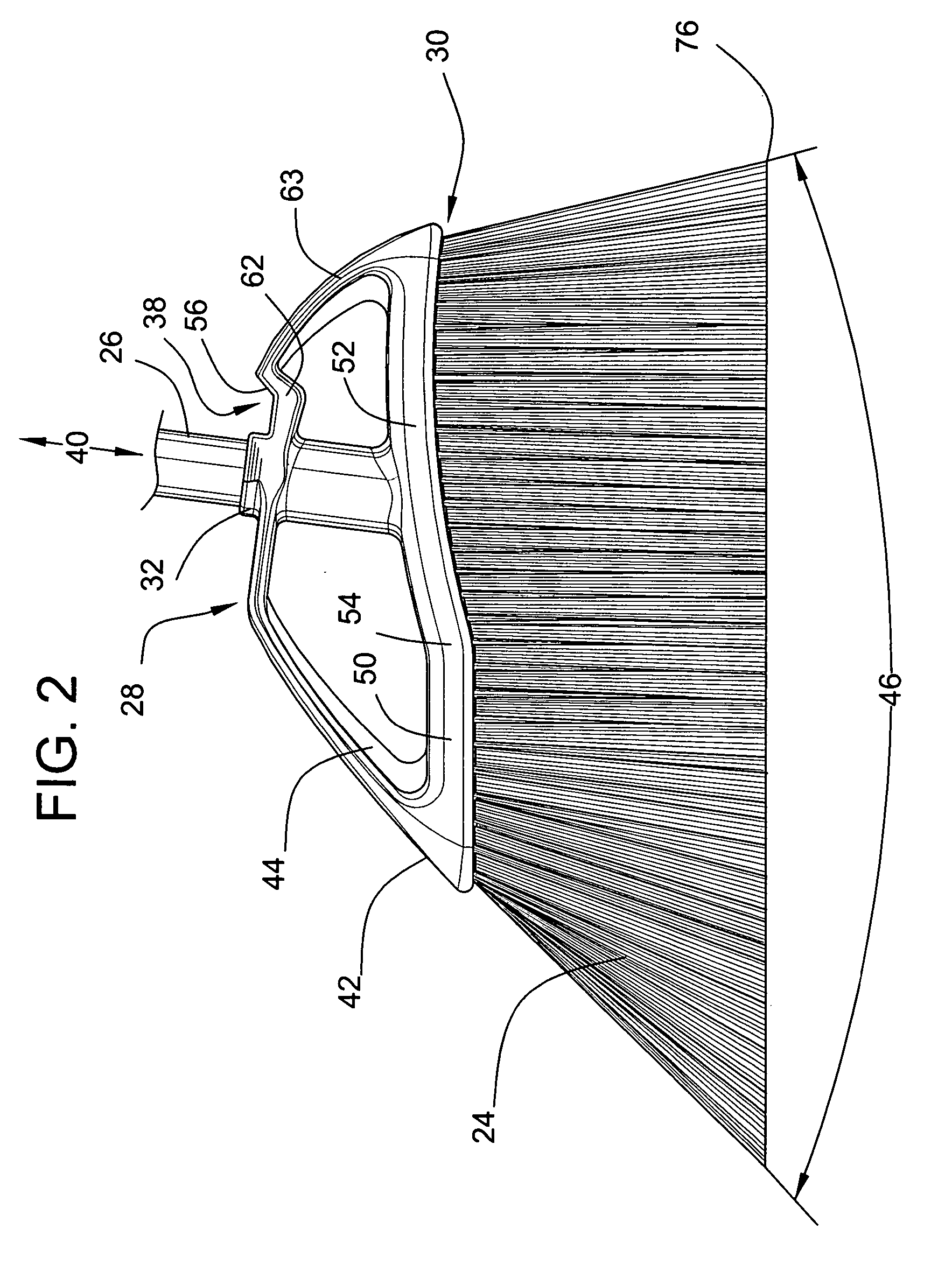

[0036] With reference to FIG. 1, the illustrated broom 20 includes a broom body 22, bristles 24, which are disposed in a plurality of bunches, and a shaft 26. The broom body 22 having a shaft side 28 and a cleaning side 30. The bristles 24 extending from the cleaning side 30 of the broom body 22. Typically, the bristles 24 include a plurality of fibers and are attached to the broom body 22. In one embodiment, the bristles 24 are stapled to the body 22. The broom body 22 includes an integrally attached shaft connector 32. The shaft 26 is adapted to be connected to the broom body 22 at the shaft connector 32 on the shaft side 28. A hanging cap 34 is disposed at the operator end 36 of the shaft 26. The components of the broom may be made of any suitable materials and by any suitable techniques. For instance, the shaft may be made of steel, the broom body and hanger cap may be made of a suitable thermoplastic, and the bristles may be made of a suitable thermoplastic material. The bristl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| broom angle | aaaaa | aaaaa |

| broom angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com