Expandable slotted tubing string and method for connecting such a tubing string

a slotted tubing and expansion method technology, applied in the direction of screw threaded joints, non-disconnectible pipe joints, fluid removal, etc., can solve the problem of bore restriction, and achieve the effect of facilitating sleeve handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

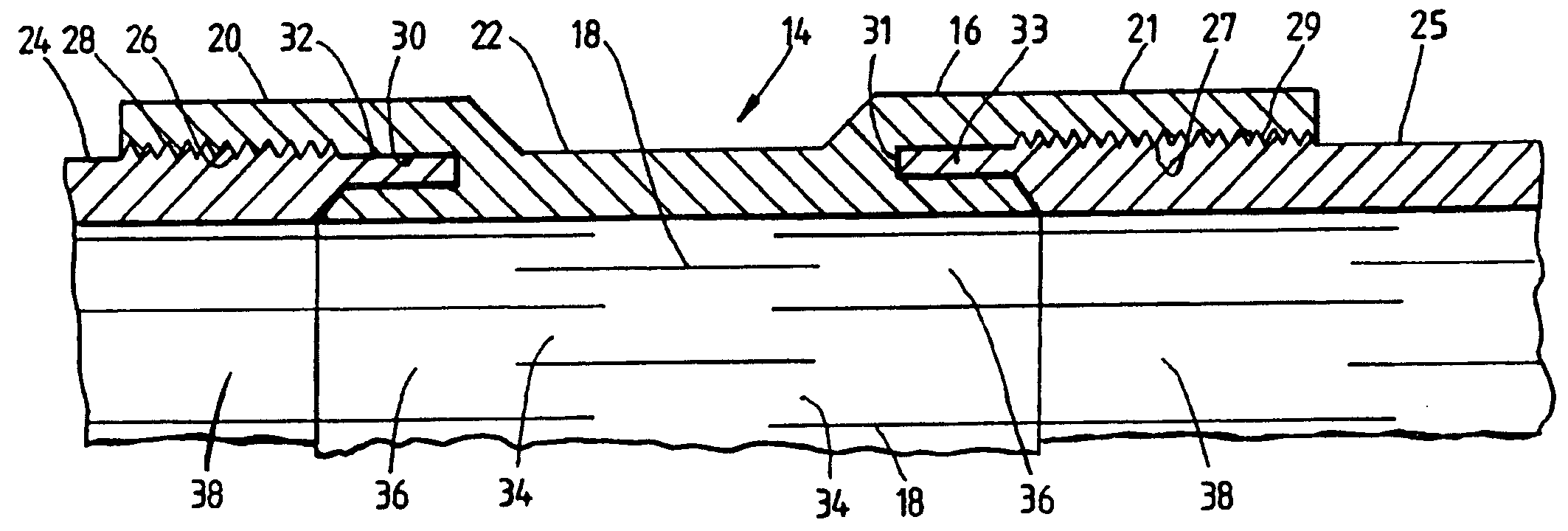

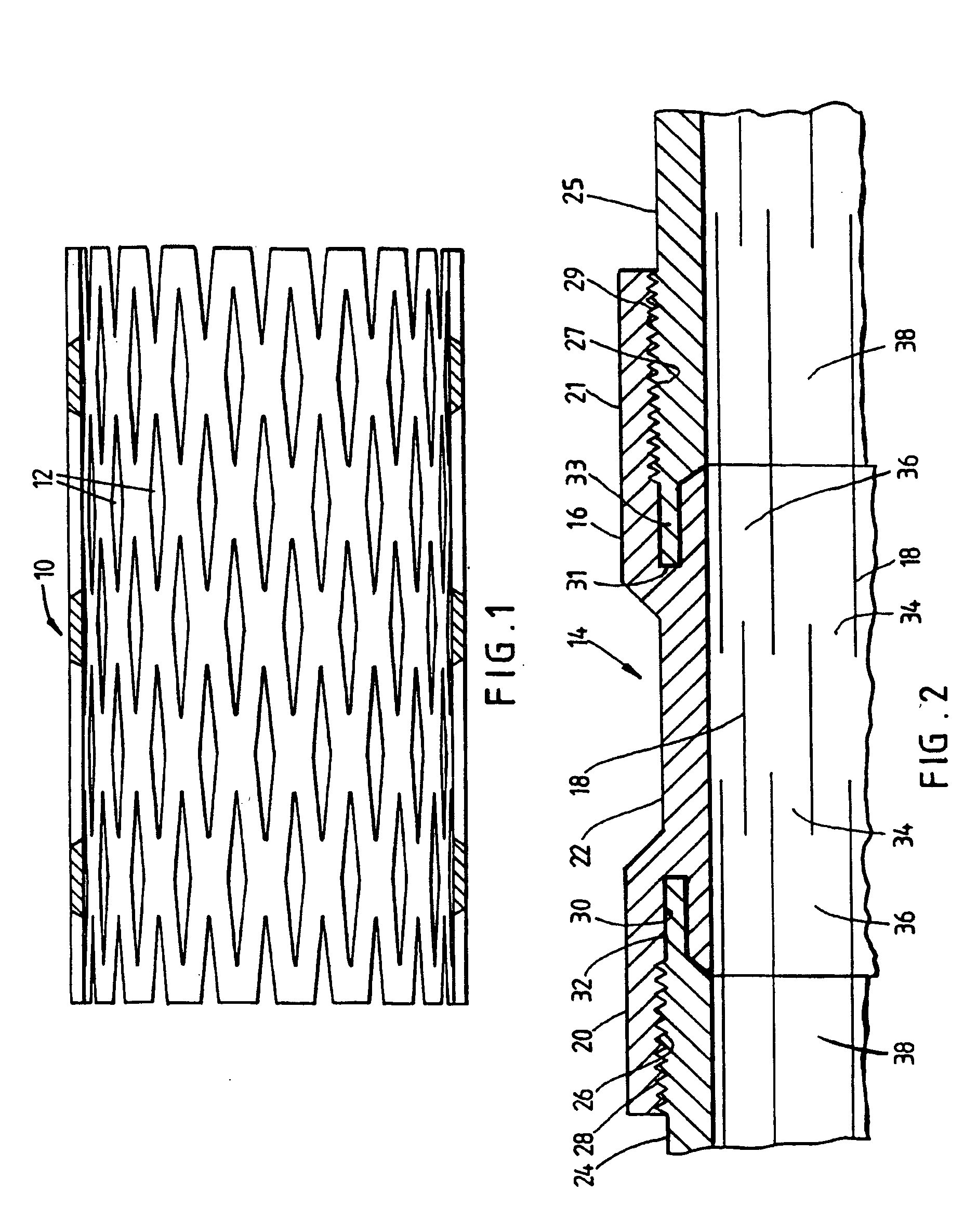

[0032] Reference is first made to FIG. 1 of the drawings, which illustrates a length of expandable tubing 10. In its initial configuration, the tubing 10 is simply a length of pipe in which a series of longitudinal slots 12 have been machined. Applying a radially outward force to the tubing wall, by passing a mandrel through the tubing, causes the tubing to expand such that the slots 12 become diamond-shaped openings.

[0033] The tubing 10 is supplied in lengths suitable for transportation and handling and these are joined to one another on surface to create a tubular string. The assembly 14 illustrated in FIG. 2 of the drawings allows lengths of expandable tubing 10 to be connected to form a string, as will now be described.

[0034] The assembly 14 comprises a tubular connector 16 defining overlapping longitudinal slots 18, the connector 16 comprising end portions 20, 21 and an intermediate portion 22. The slots 18 extend over the whole length of the connector 16, but the only slot o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lengths | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com