Droplet dispensing system

a droplet and liquid technology, applied in the field of liquid dispensing systems, can solve the problems of difficult control of the precise volume of dispensed sample using capillary tubes, low injection efficiency inherent in capillary tubes, contamination of capillary tubes, etc., and achieve the effects of enhancing liquid sample application, efficient and rapid dispensing, and fast and flexibl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

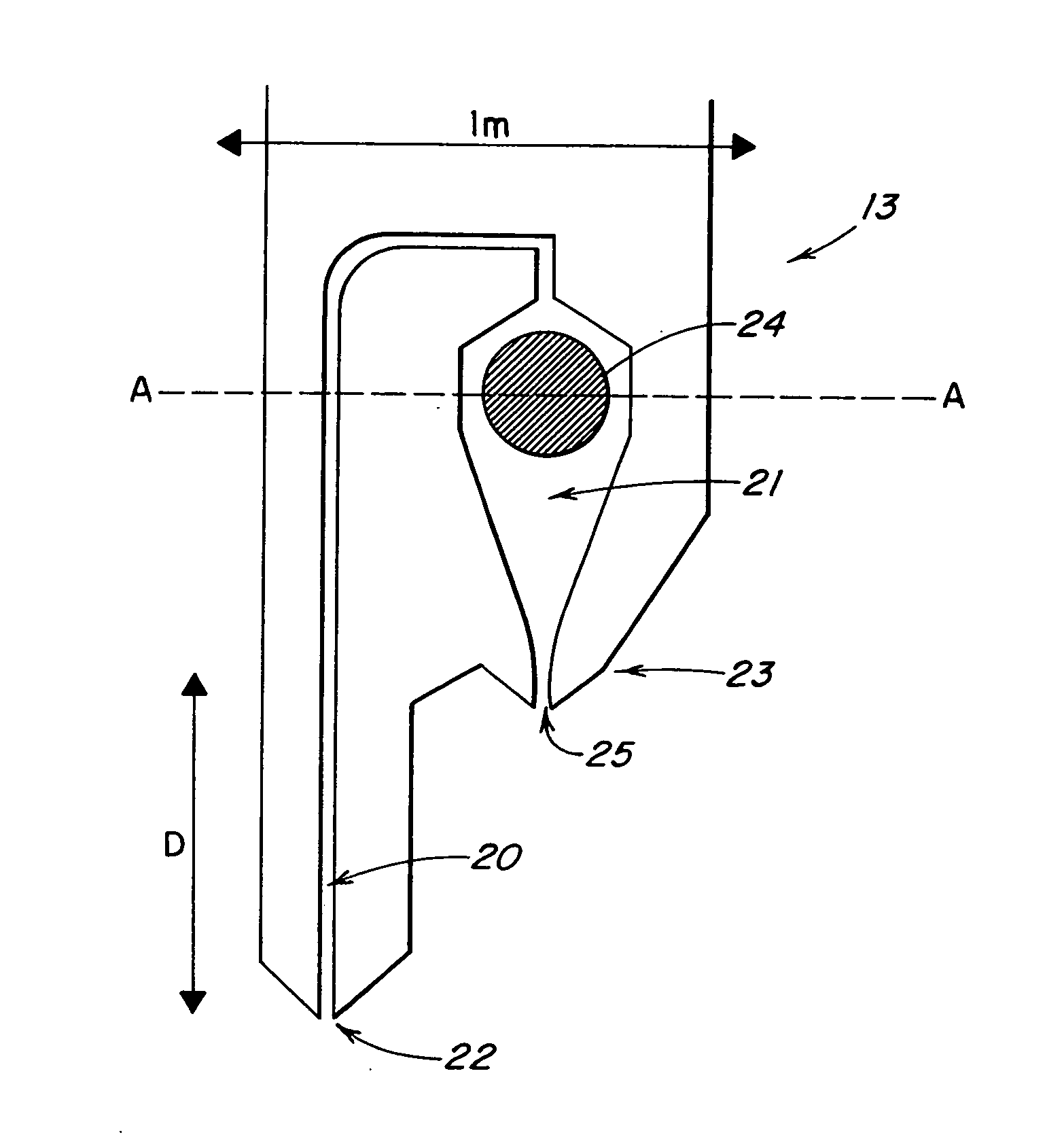

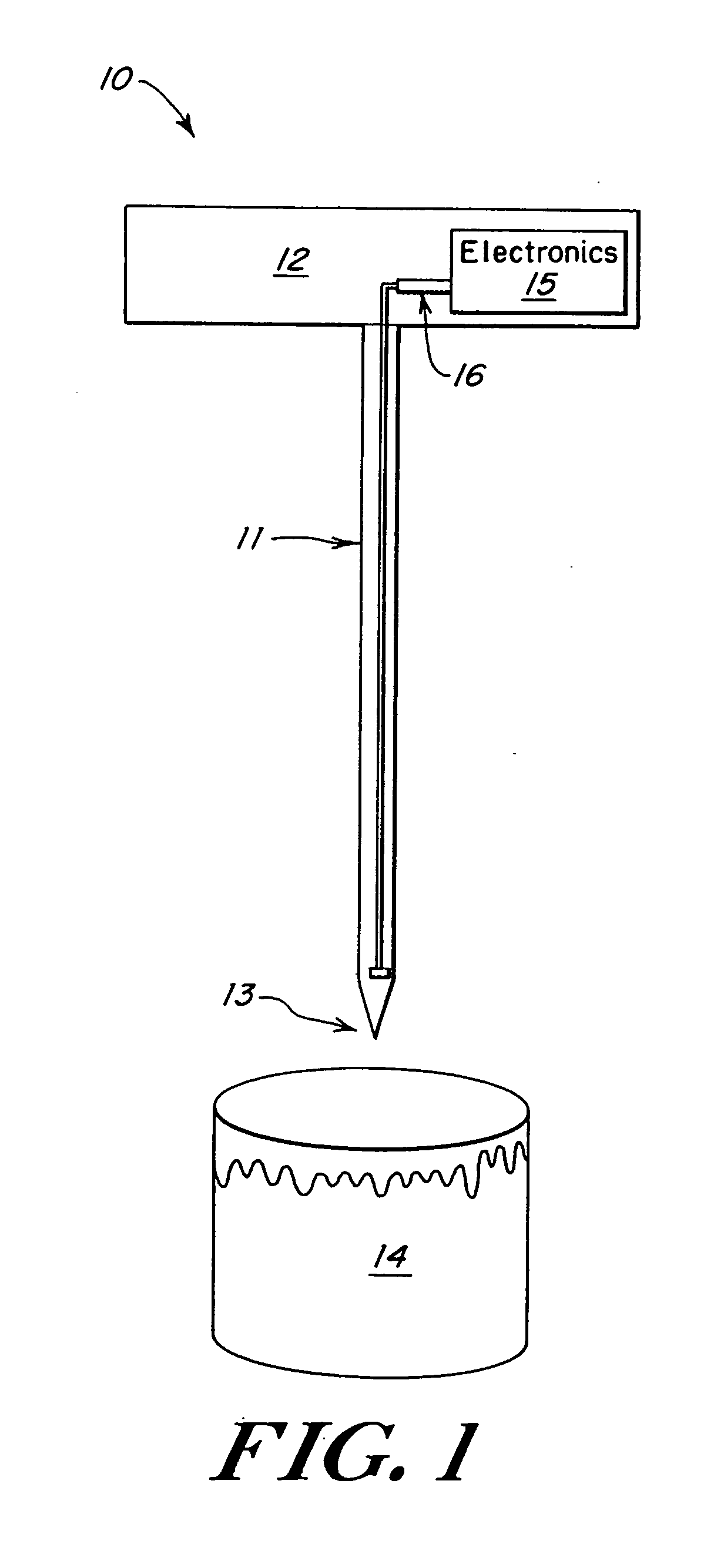

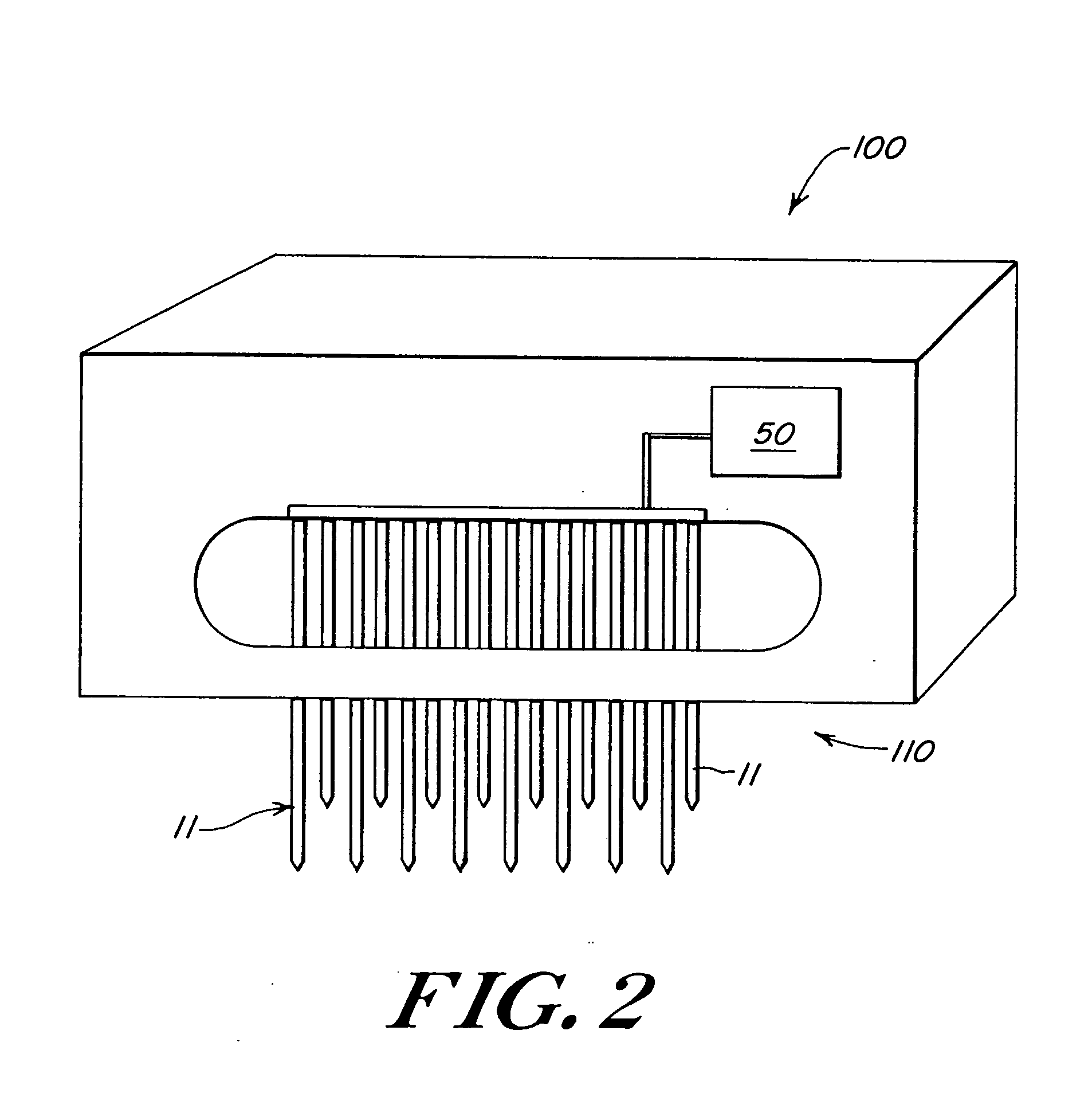

[0019] The present invention provides a droplet dispensing system for forming and dispensing liquid droplets of a sample for fluidic systems. The droplet dispensing system of the present invention provides precise sample uptake and delivery of a liquid sample to a sample handling system in the form of sub-micron-sized droplets. The droplet dispensing system is suitable for use in a basic research or a commercial environment. The droplet dispensing system significantly improves sample introduction into a sample handling system by increasing the efficiency, speed and controllability of forming and dispensing droplets while significantly reducing waste and contamination. Those skilled in the art will appreciate that the present invention may be implemented in a number of different applications and embodiments and is not specifically limited in its application to the particular embodiment depicted herein.

[0020] The droplet dispensing system of the present invention provides significant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com