Vehicle headlamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] An embodiment of the invention will now be described by reference to the drawings.

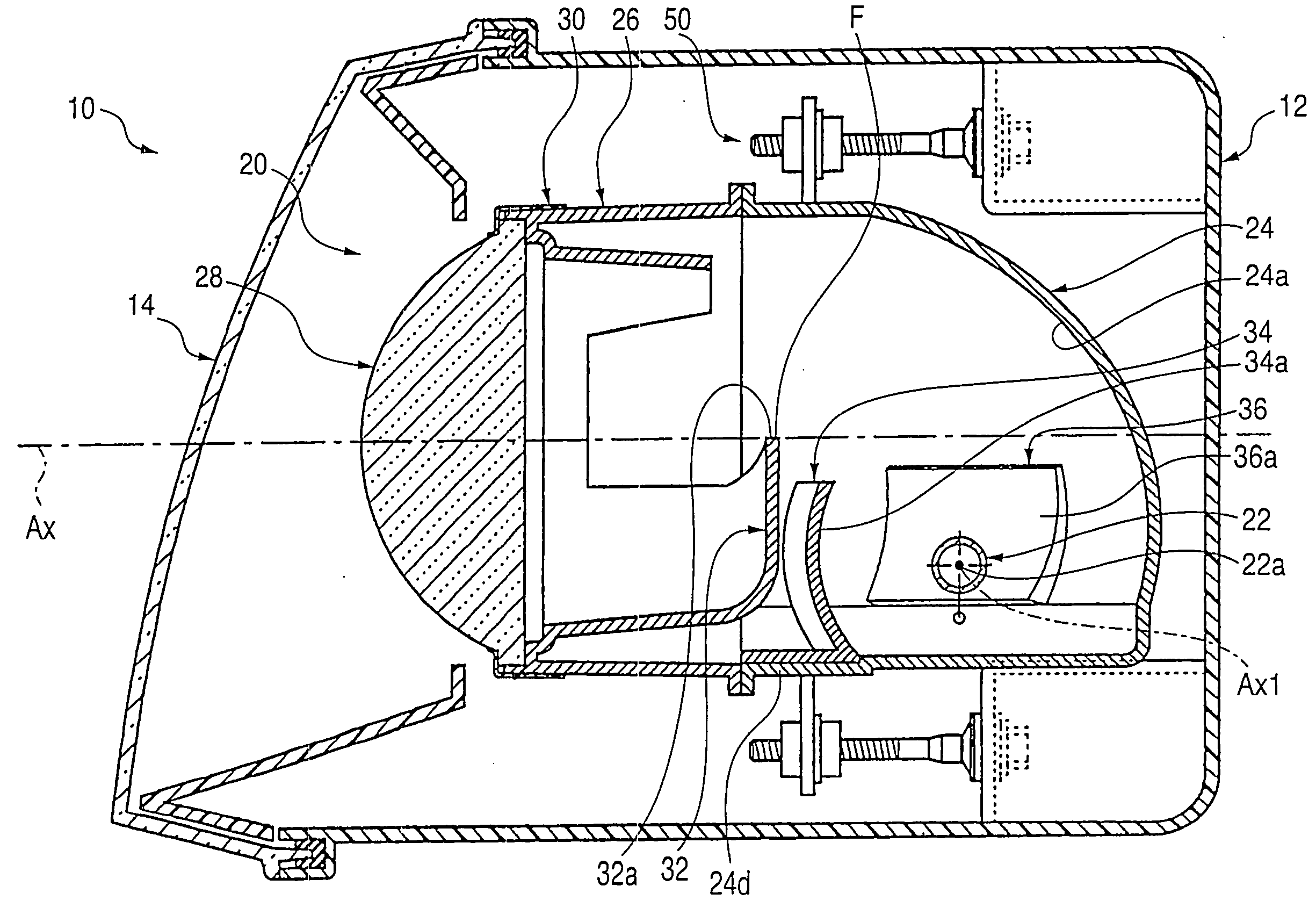

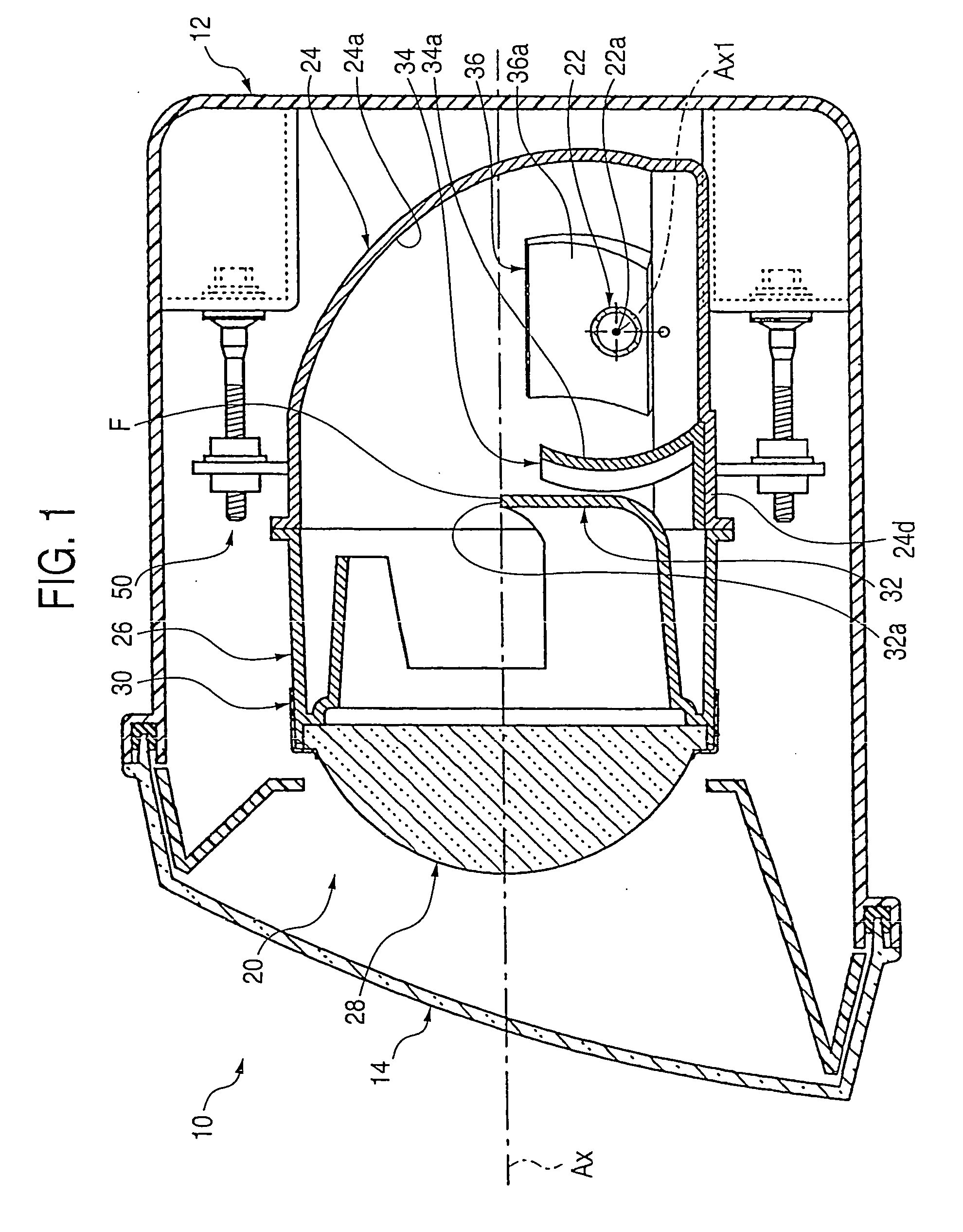

[0034]FIG. 1 is a sectional side view of a vehicle headlamp embodying the invention.

[0035] As shown in FIG. 1, a vehicle headlamp 10 embodying the invention is disposed in the right front end portion of a vehicle. A lighting device unit 20 having an optical axis Ax extending in the longitudinal direction of the vehicle is housed in a lamp chamber. The lamp chamber includes a lamp body 12 and a transparent light-permeable cover 14 mounted to a front end opening of the lamp chamber. The lighting device unit 20 is tiltable in vertical and horizontal directions via an aiming mechanism 50.

[0036] Upon completion of aiming adjustment made by the aiming mechanism 50, the optical axis Ax of the lighting device unit 20 is extended downward by approximately 0.5-0.6° with respect to the longitudinal direction of the vehicle.

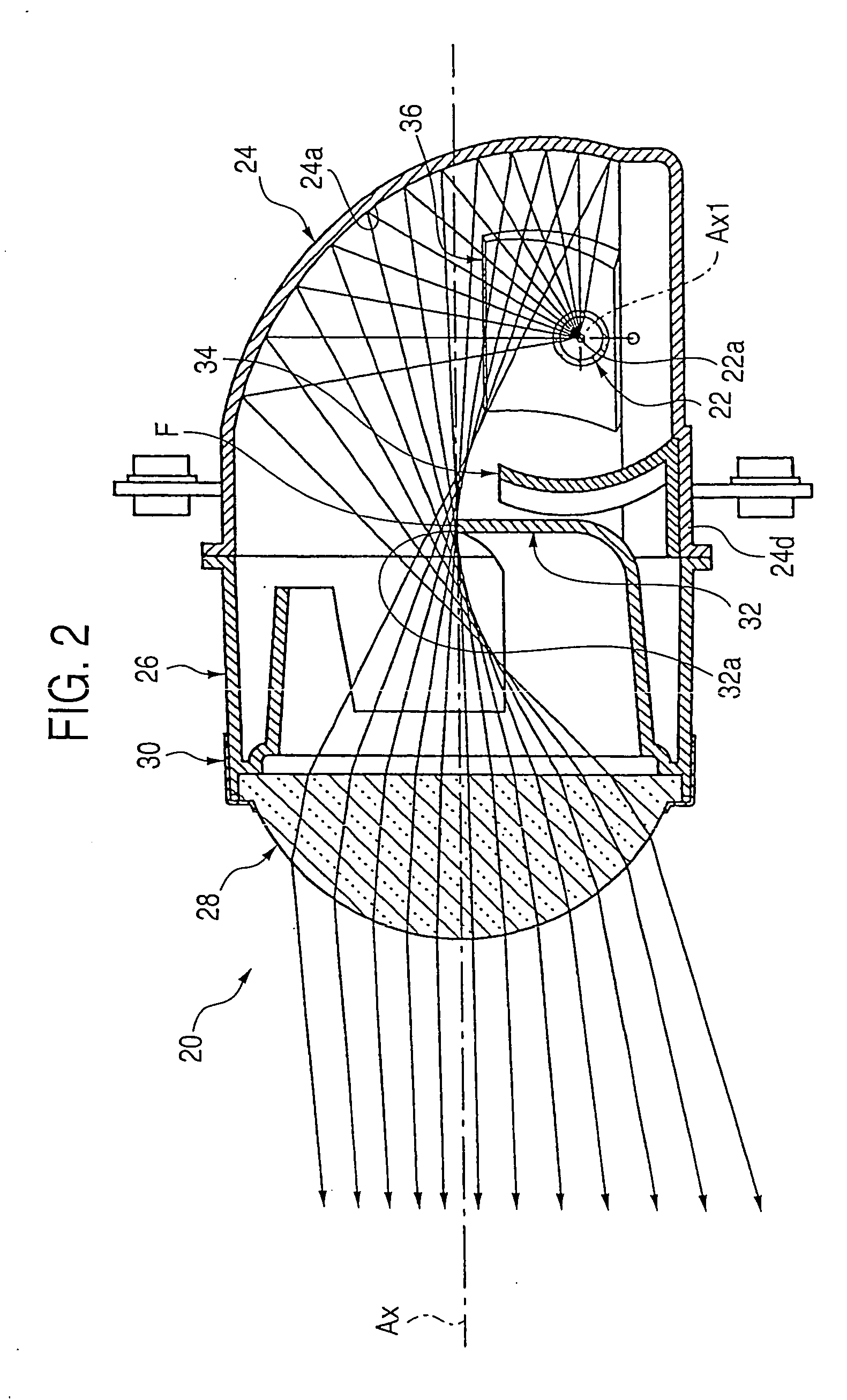

[0037]FIGS. 2 and 3 are sectional side views of the single lighting device unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com