Acetylene cylinder manifold assembly

a technology assembly, which is applied in the direction of functional valve types, water supply installation, separation processes, etc., can solve the problems of large volume of individual cylinders, detonation of gas cylinders, and limited gas capacity of acetylene gas cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

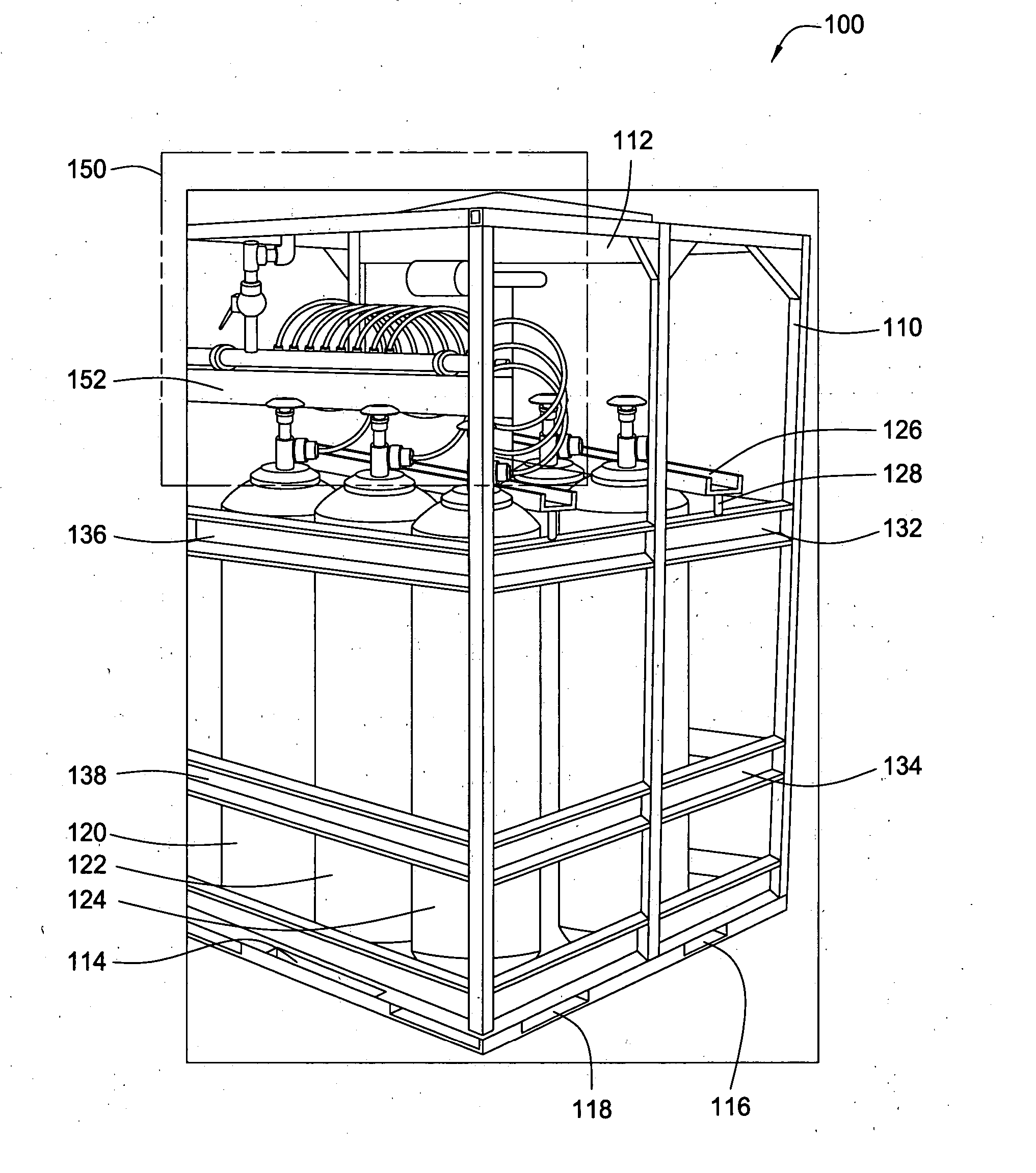

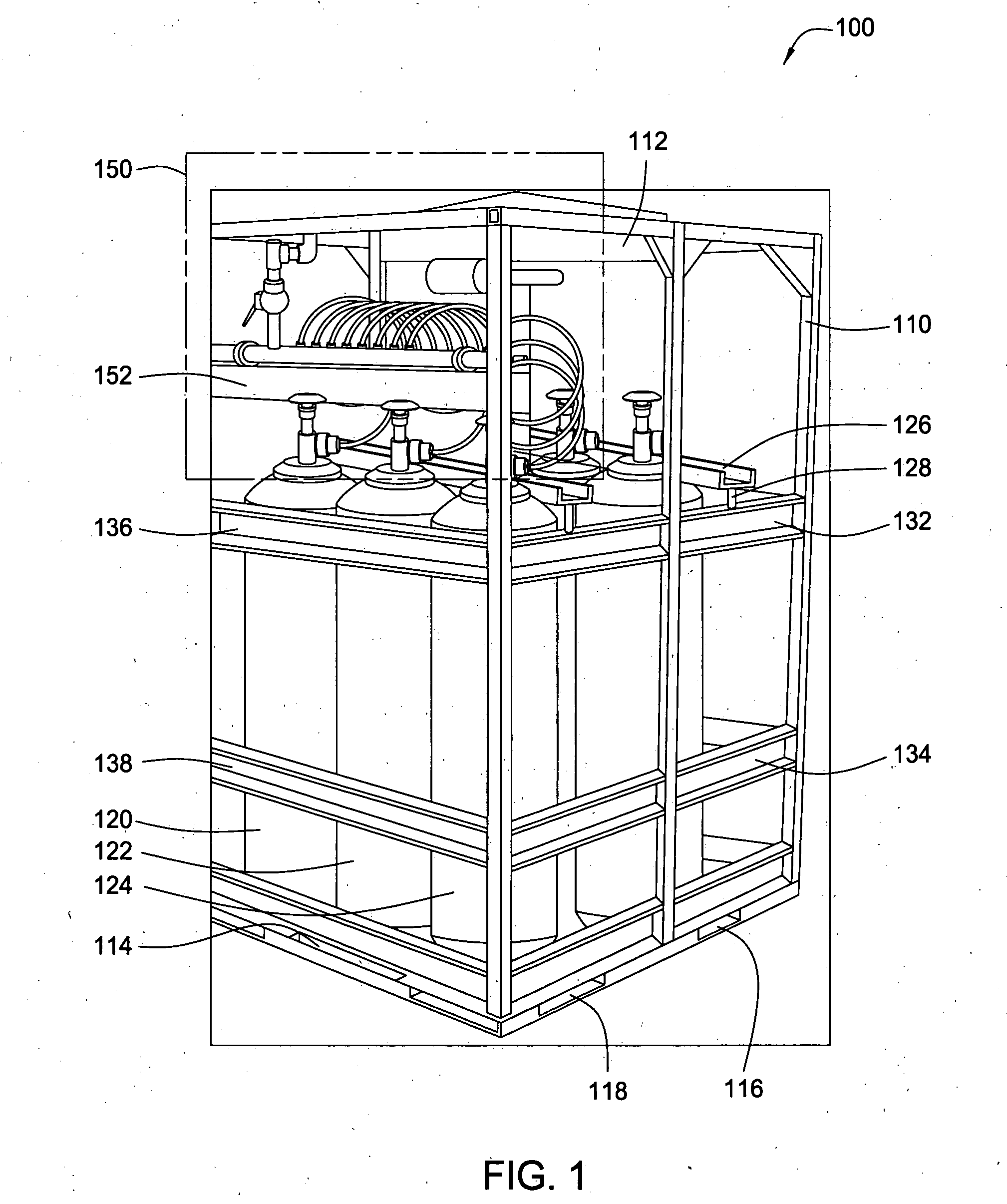

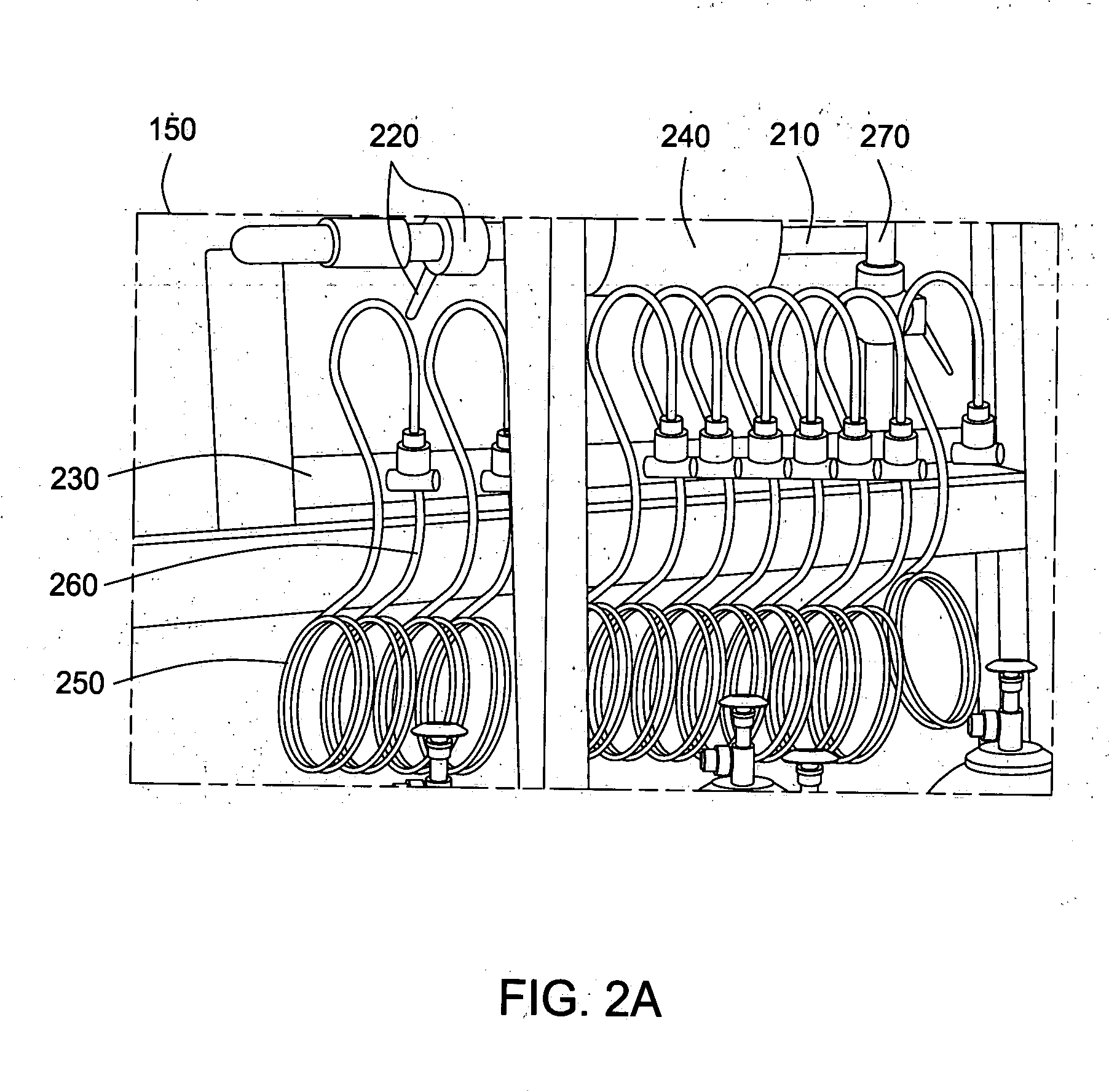

[0023] The present invention is generally directed to an apparatus and method for simultaneously filling a plurality of, acetylene cylinders and more particularly to an acetylene cylinder filling / dispensing system. The acetylene cylinder filling / dispensing system includes an acetylene cylinder assembly having a plurality of acetylene cylinders. Accordingly, by assembling the plurality of acetylene cylinders in the acetylene cylinder assembly, a relatively increased acetylene gas capacity is provided by joining the gas volumes of the assembled gas cylinders together. This is beneficial for larger applications requiring larger gas volumes than provided with separate acetylene gas cylinders.

[0024] The plurality of acetylene cylinders are filled with acetylene gas from an acetylene gas container. In one embodiment, the acetylene gas container is connected to an acetylene gas supply adapted for supplying the acetylene gas to the acetylene cylinder assembly. The gas supply may include a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com