Stackable chair with modular slide-on seat back

a seat back and modular technology, applied in the field of stackable chairs, can solve the problems of affecting the stability of the chair, the loosening of the fastener used to hold the seat back assembly to the frame, and the aging of the chair, so as to reduce material and labor costs, facilitate and inexpensively manufacture and assembly, and reduce the effect of material and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

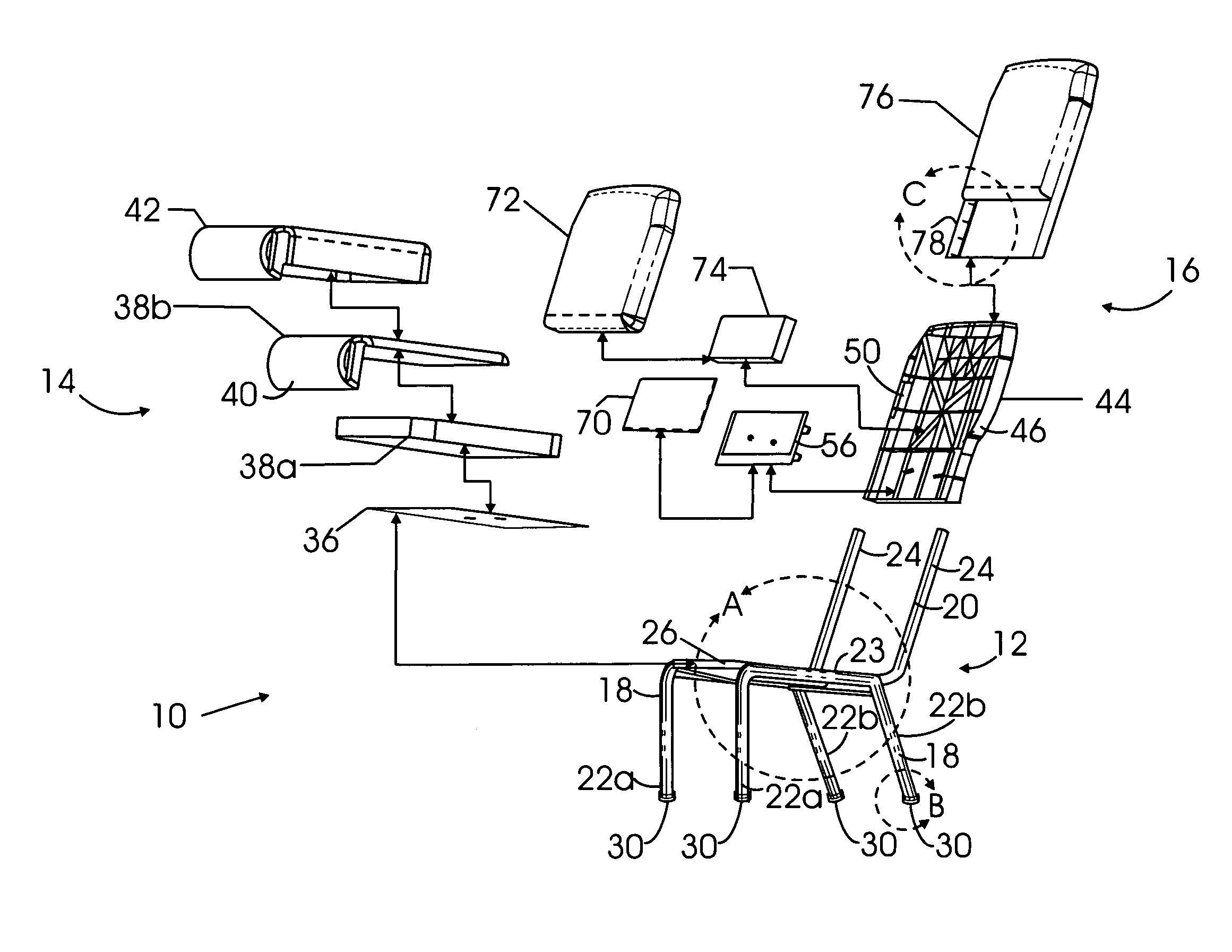

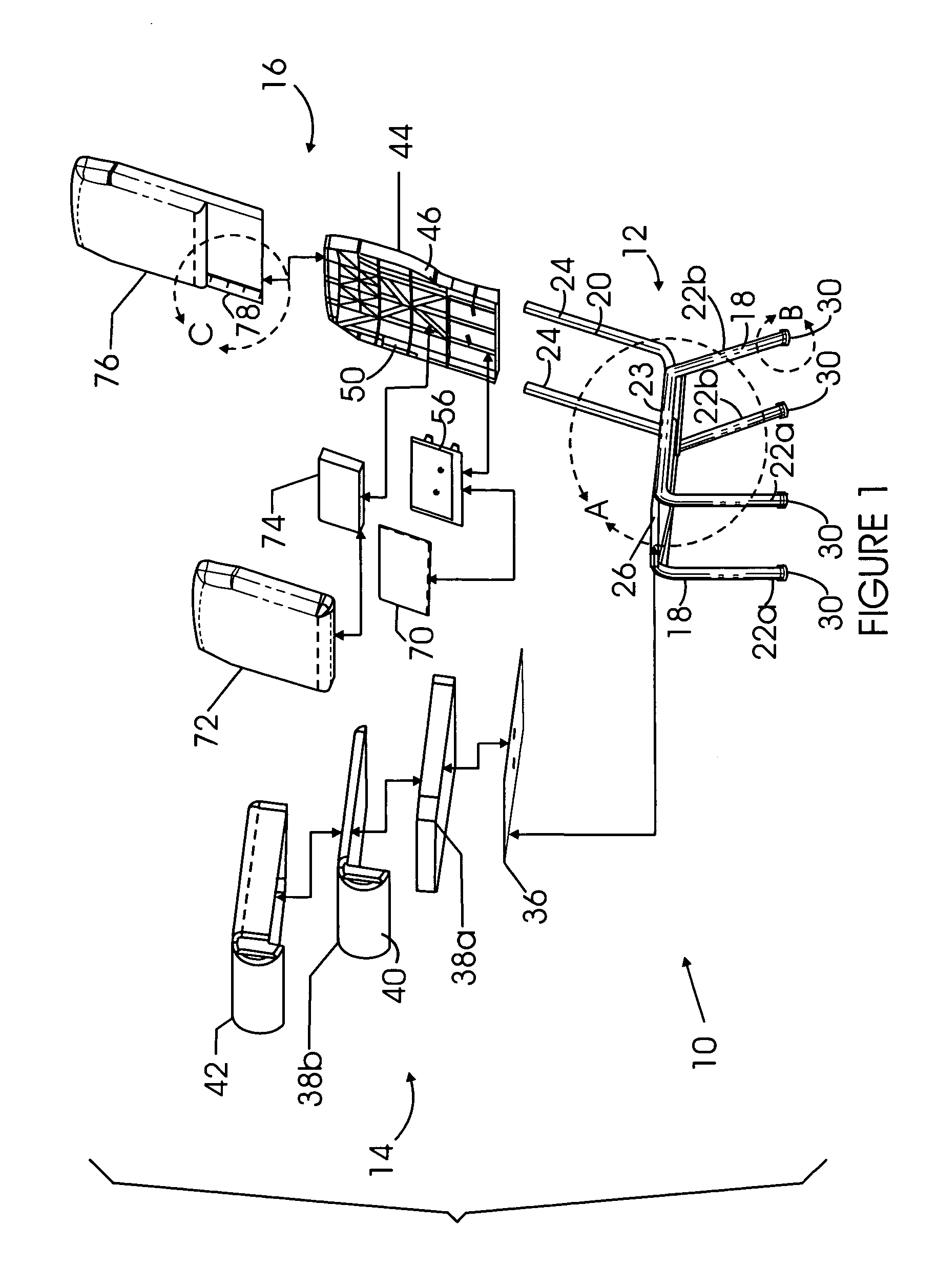

[0043] An exploded perspective view of an exemplary embodiment of a stackable chair 10 in accordance with the present invention is illustrated in FIG. 1. As illustrated therein, the chair comprises a plurality of assemblies, or modules, including a frame module 12, a seat module 14, and a back module 16.

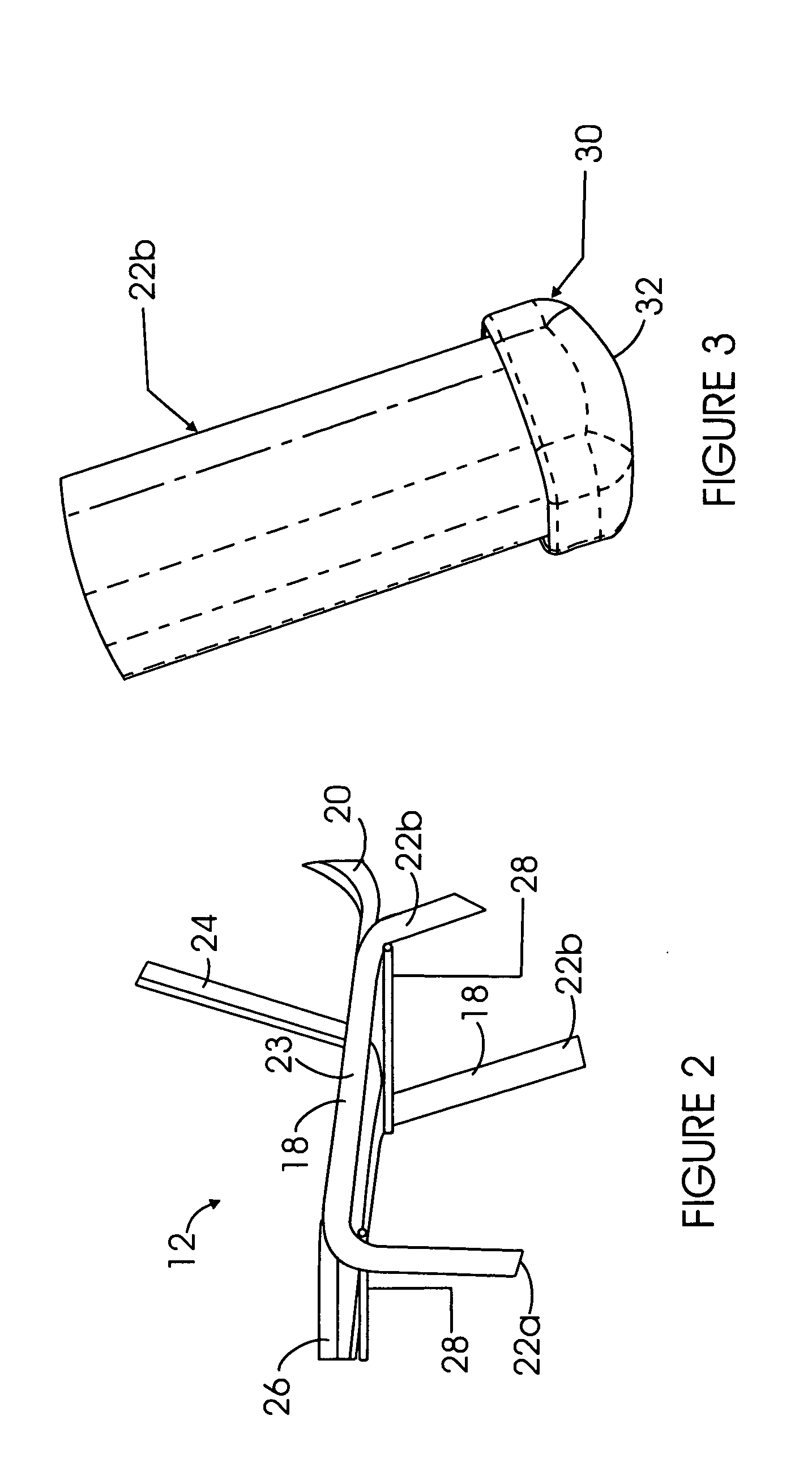

[0044] As illustrated in detail A of FIG. 1 and the enlarged view thereof of FIG. 2, the frame module 12 comprises a pair of generally inverted U-shaped tubular side frame members 18, and a tubular seat and back frame member 20. The tubular members 18 and 20 are preferably formed of steel or aluminum tubing, with open ends, and, as illustrated, they are generally square in cross-section. It will be appreciated, however, that that other cross-sectional shapes are possible, and may be preferable, depending on the application at hand.

[0045] Each of the side frame members 18 includes a pair of substantially vertical portions, each of which forms a front chair leg 22a and a rear chair l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com