Vapor collection and treatment of off-gas from an in-situ thermal desorption soil remediation system

a technology of thermal desorption soil and vapor collection system, which is applied in the field of soil remediation, can solve the problems of high cost of methods, high capital cost, and inability to meet the needs of the public, and achieve the effect of reducing capital cost, transportation cost and operating expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

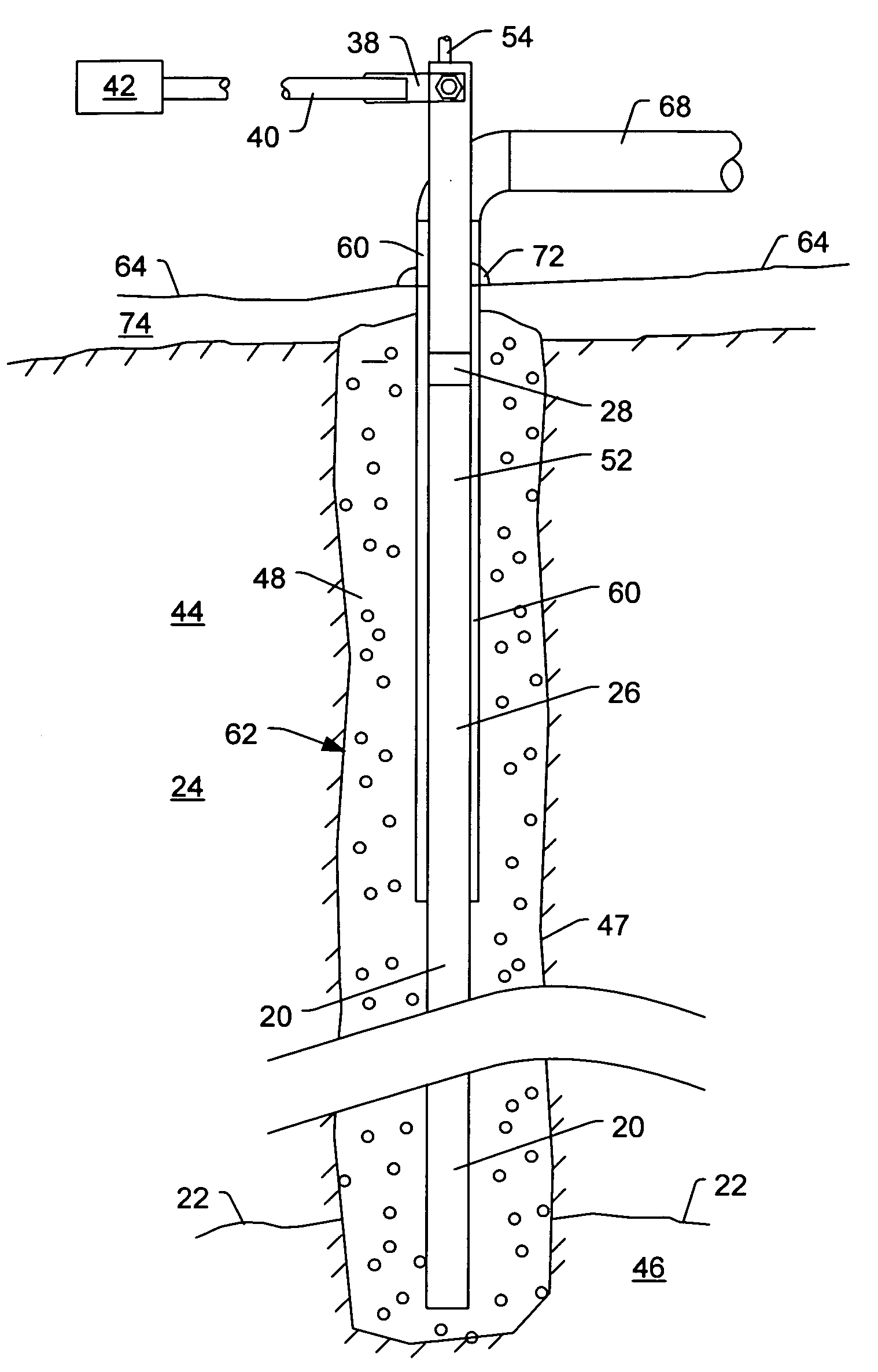

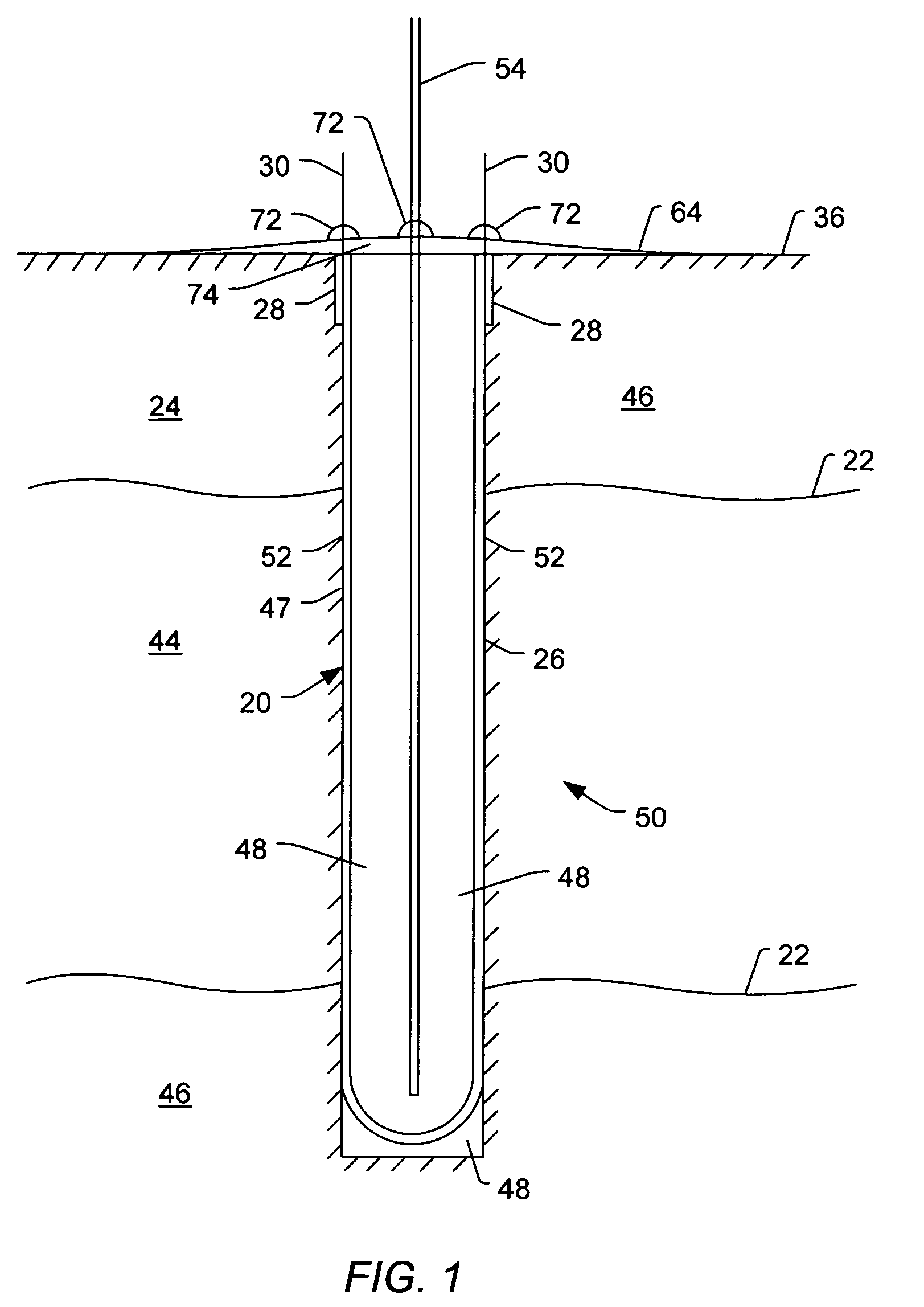

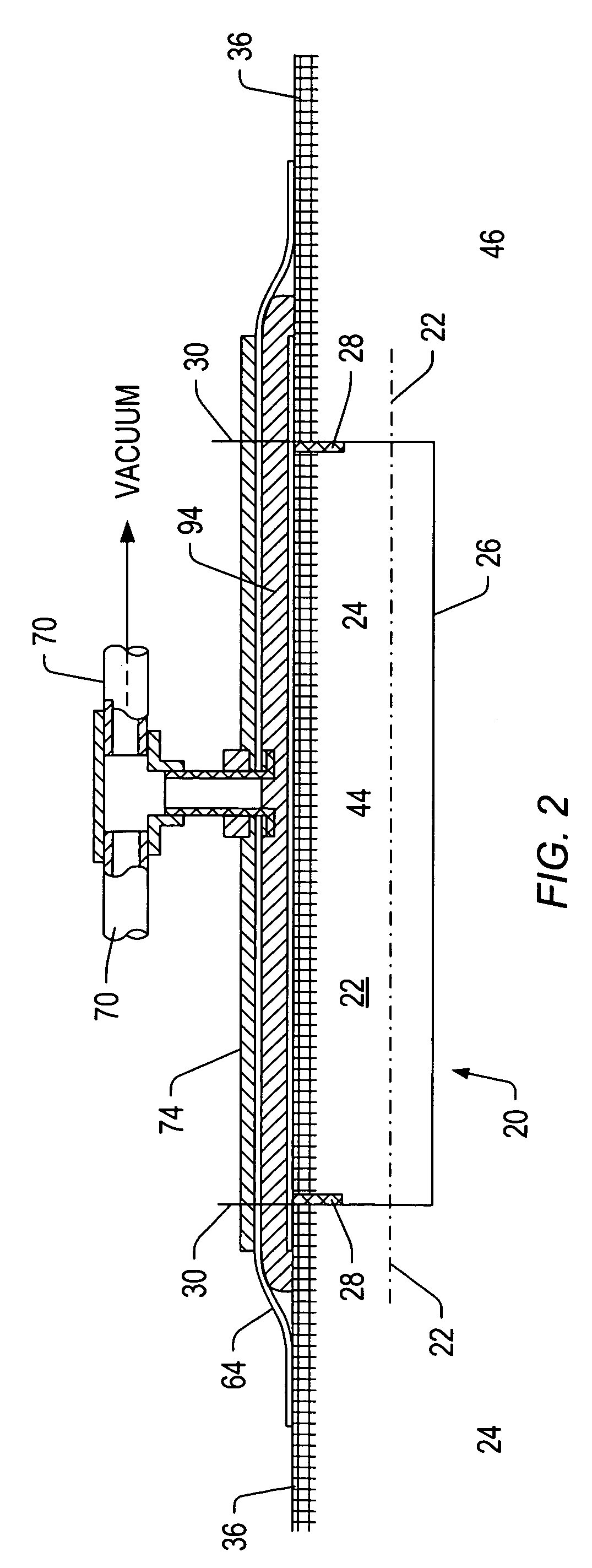

[0065] As depicted in FIG. 1, an in situ thermal desorption soil remediation process may use strip heaters 20 to conductively apply heat to contaminated region 22 of soil 24. The soil remediation process may be used to remove contaminants from the soil 24. A vacuum may be applied to the soil 24 along with conductive heat to remove contaminants from the soil. FIG. 1 shows an embodiment of a strip heater 20 vertically positioned in contaminated soil 24. FIG. 2 shows an embodiment of a strip heater 20 horizontally positioned in soil 24. Strip heaters 20 may also be inserted in soil 24 in non-vertical and non-horizontal (e.g., angled) orientations.

[0066] A strip heater 20 may include heater section 26, transition sections 28, and pins 30. The heater section 26 may be formed of a high temperature, chemical resistant metal. The heater section 26 may be formed of a stainless steel, including but not limited to type 304 stainless steel, type 309 stainless steel, type 310 stainless steel, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com