Dry cleaning machine and method of dry cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

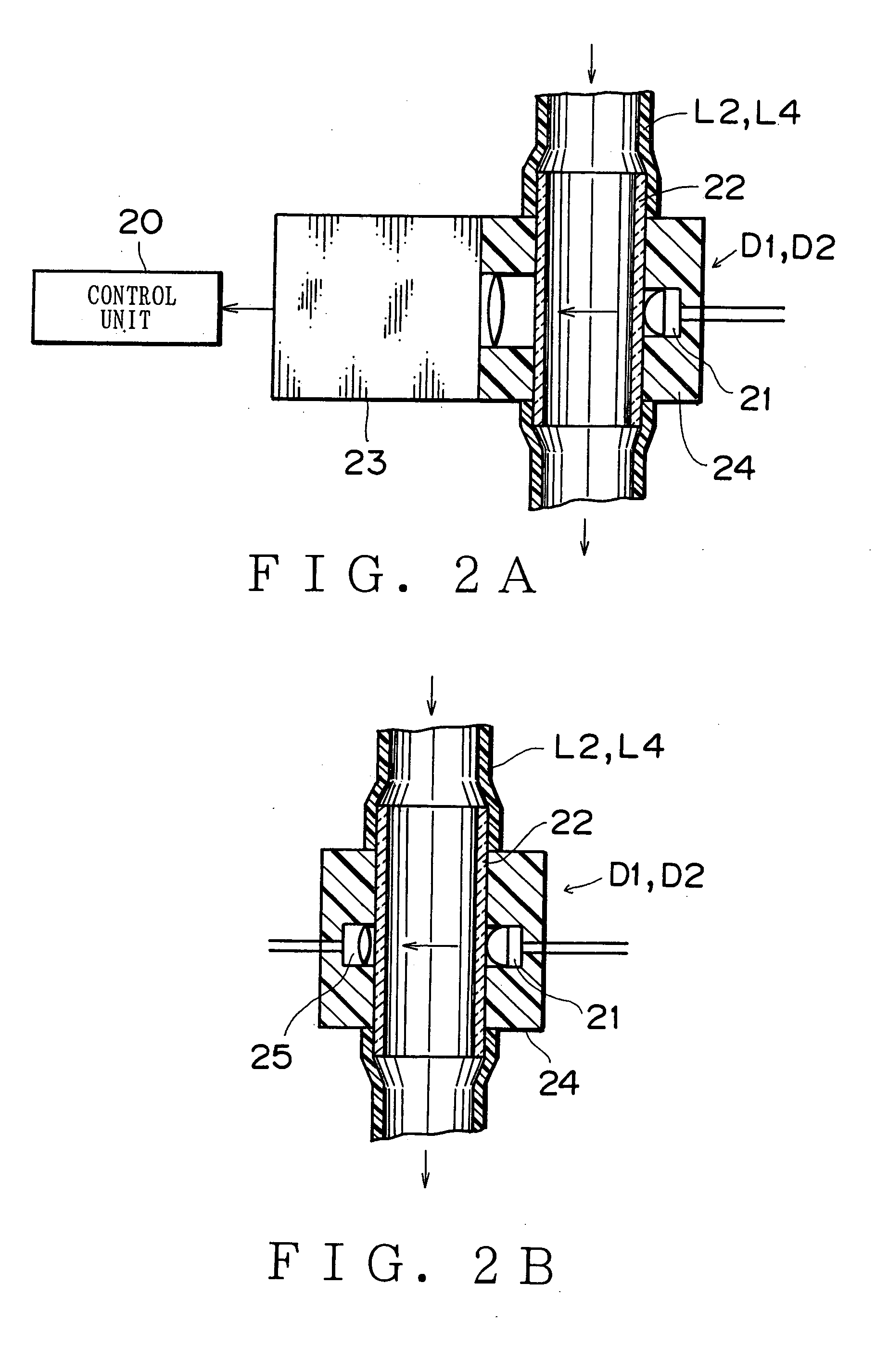

[0035] Some embodiments of dry cleaning machines and cleaning methods according to this invention will now be described with reference to the attached drawings.

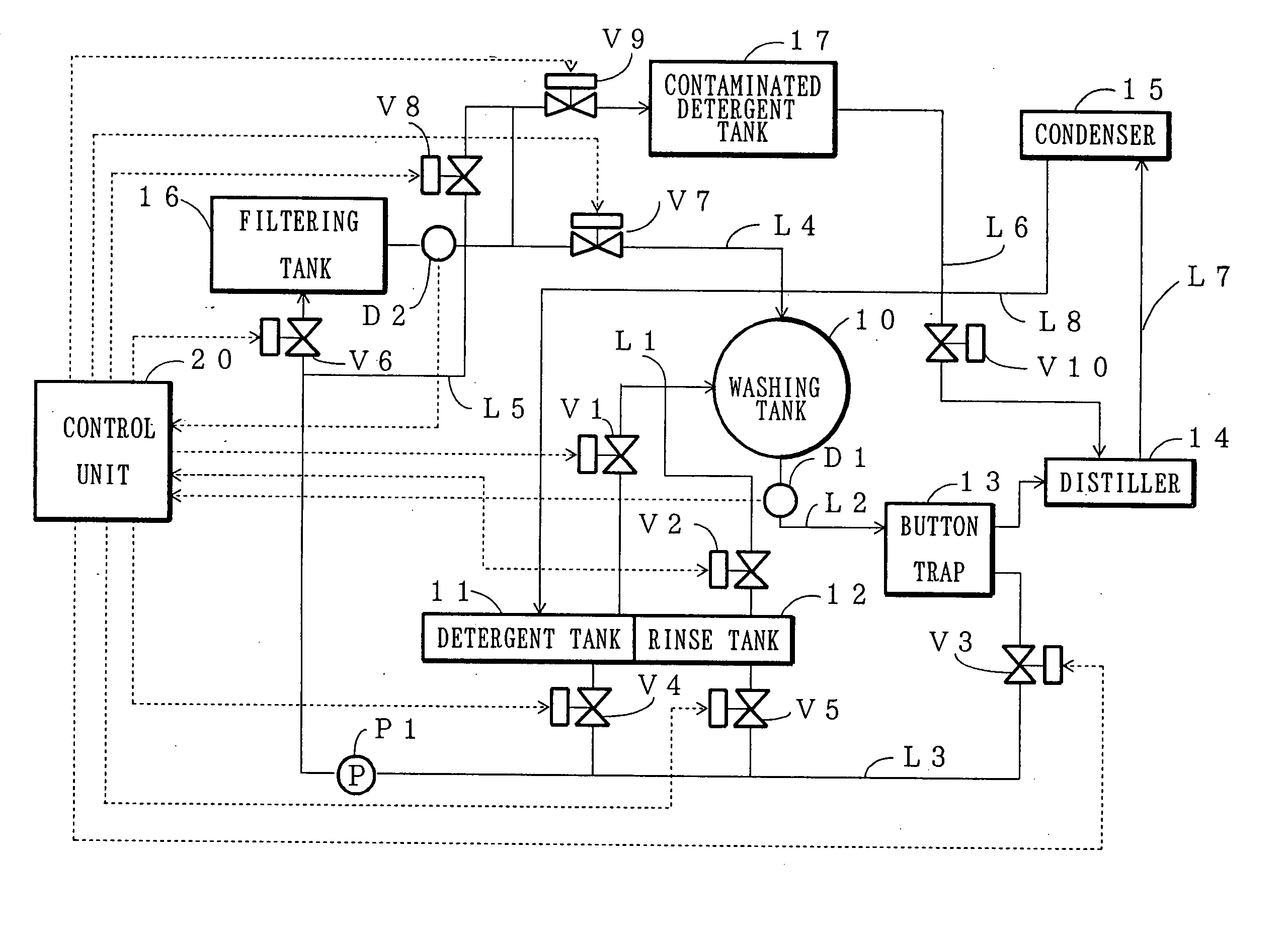

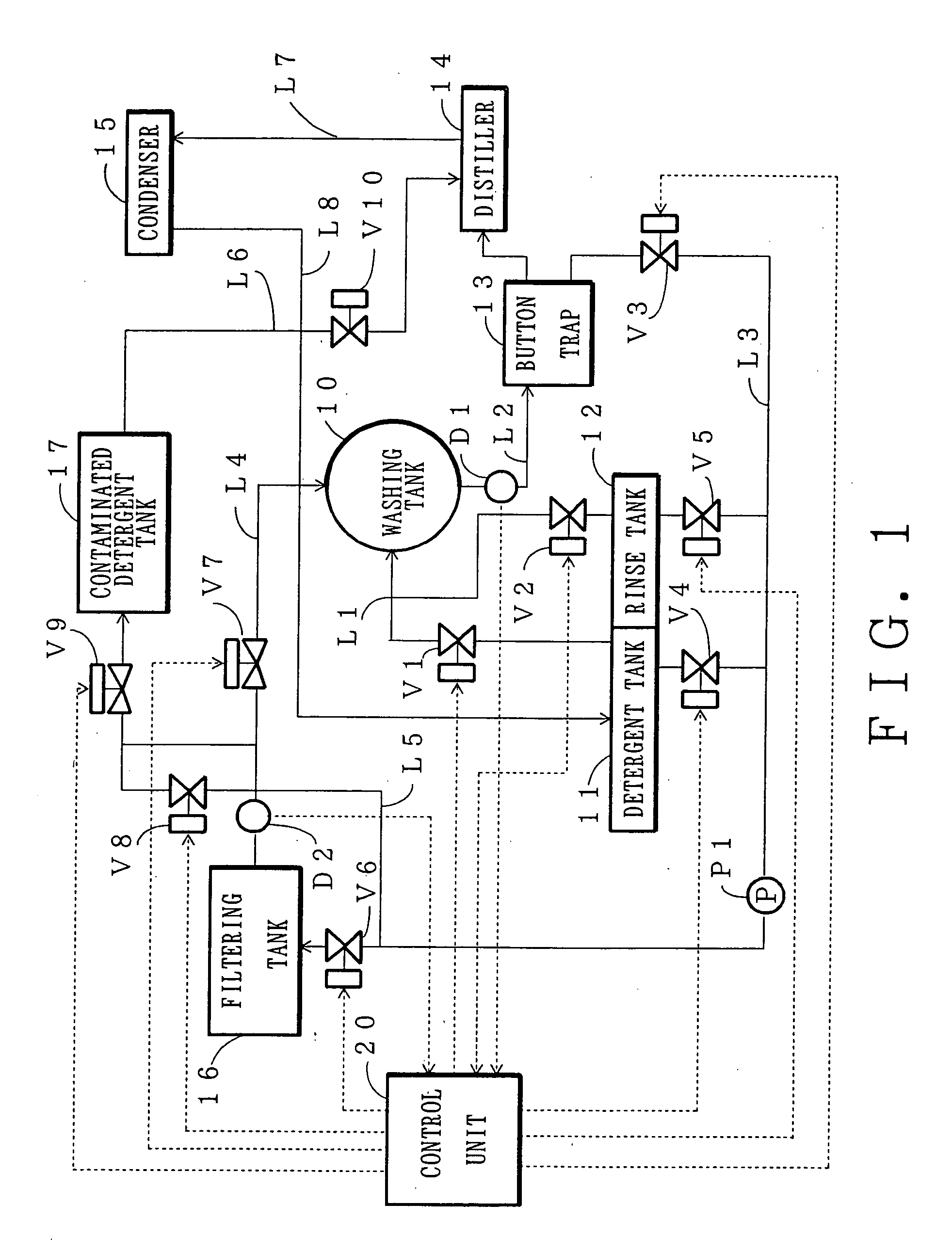

[0036]FIG. 1 is showing a block diagram of one embodiment of a dry cleaning machine according to this invention. In FIG. 1, a washing tank 10 is a shower drum type for washing the washing and preferably soaking type, shower type or jet type is effective and also combination type of these types is effective. A detergent tank 11 stores detergent and a rinse tank 12 stores rinse. Washing is done after inputting the washing and detergent (tetrachloroethylene or the like) into the washing tank 10. The detergent for initial use can be supplied directly through fresh detergent line L1 to the washing tank 10 or can also be supplied through circulating line L3, L4.

[0037] The detergent, discharged from the washing tank 10, is sent by pressure to the filtering tank 16 through a detergent discharging line L2, next a button trap 13 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com