Polishing pad having a sealed pressure relief channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

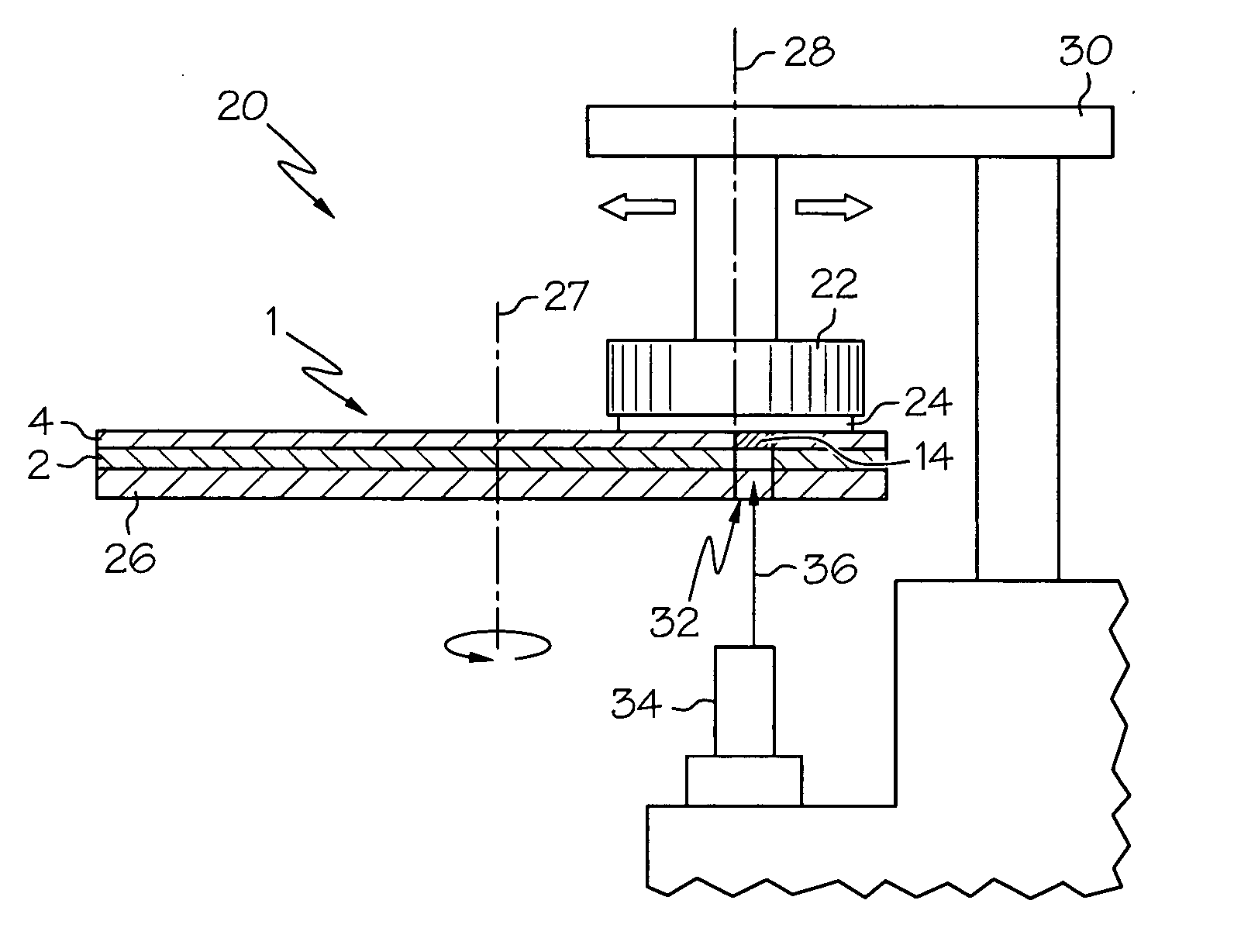

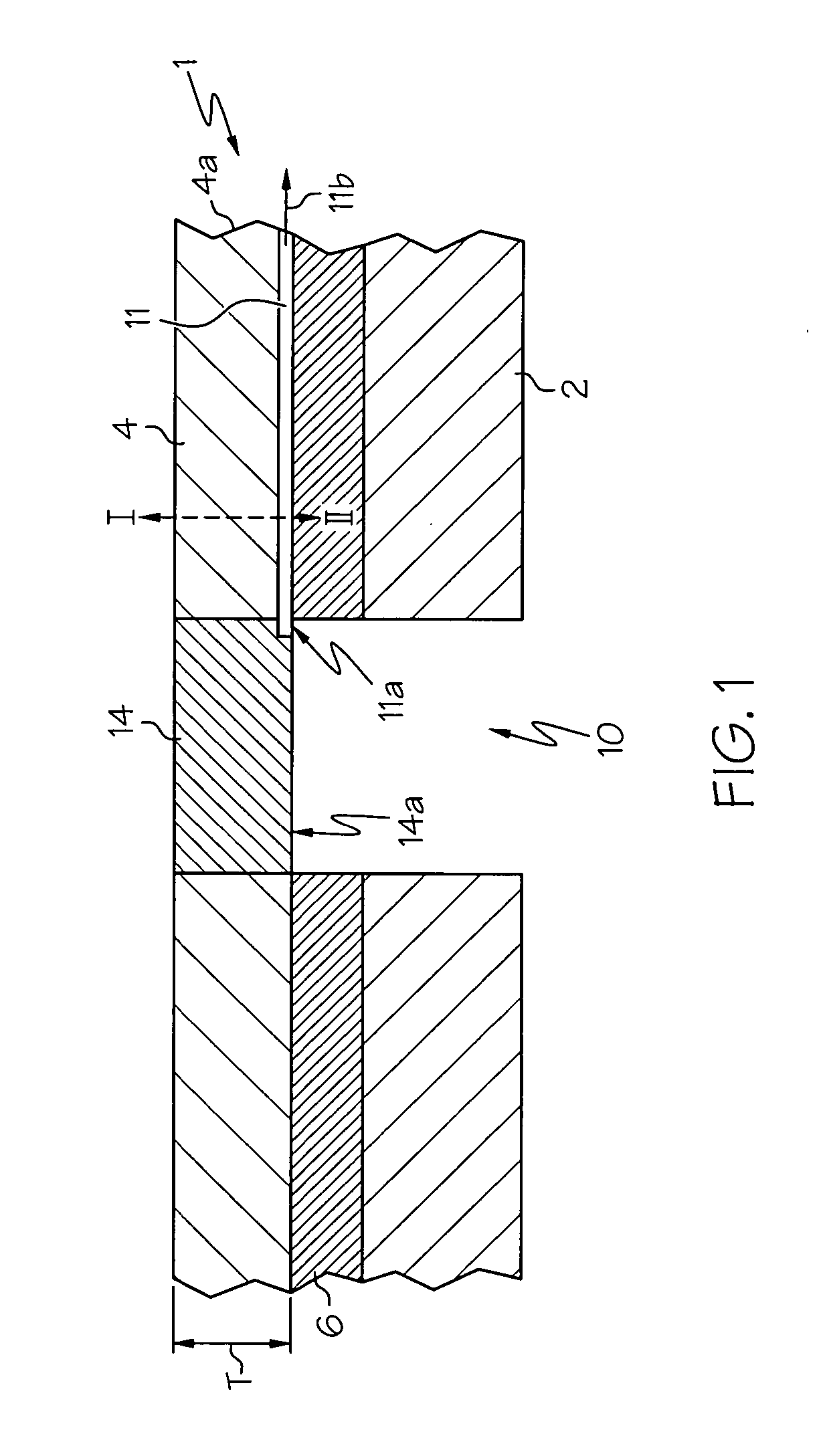

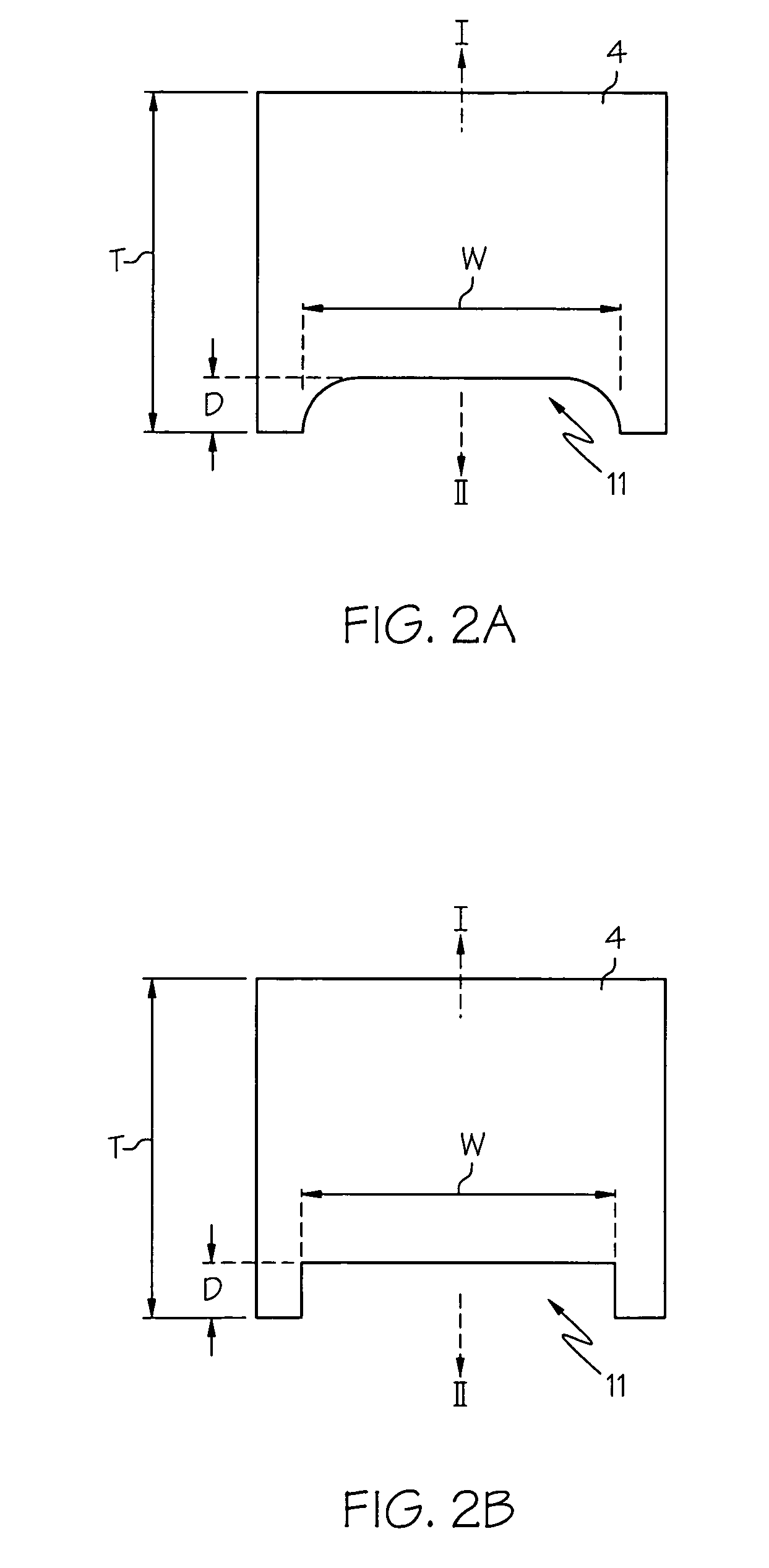

[0019] Referring now to FIG. 1, a polishing pad 1 of the present invention is shown. Polishing pad 1 comprises a polishing layer 4 and an optional bottom layer 2. Note, polishing layer 4 and bottom layer 2 may individually serve as a polishing pad. In other words, the present invention may be utilized in the polishing layer 4 alone, or in the polishing layer 4 in conjunction with the bottom layer 2, as a polishing pad. The bottom layer 2 may be made of felted polyurethane, such as SUBA-IV™ pad manufactured by Rohm and Haas Electronic Materials CMP Inc. (“RHEM”), of Newark, Del. The polishing layer 4 may comprise a polyurethane pad (e.g., a pad filled with microspheres), such as, IC 1000™ pad by RHEM. Polishing layer 4 may optionally be texturized as desired. A thin layer of pressure sensitive adhesive 6 may hold the polishing layer 4 and the bottom layer 2 together. The adhesive 6 may be commercially available from 3M Innovative Properties Company of St, Paul, Minn.

[0020] Polishing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com