Case bottom for large caliber ammunition and method for producing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

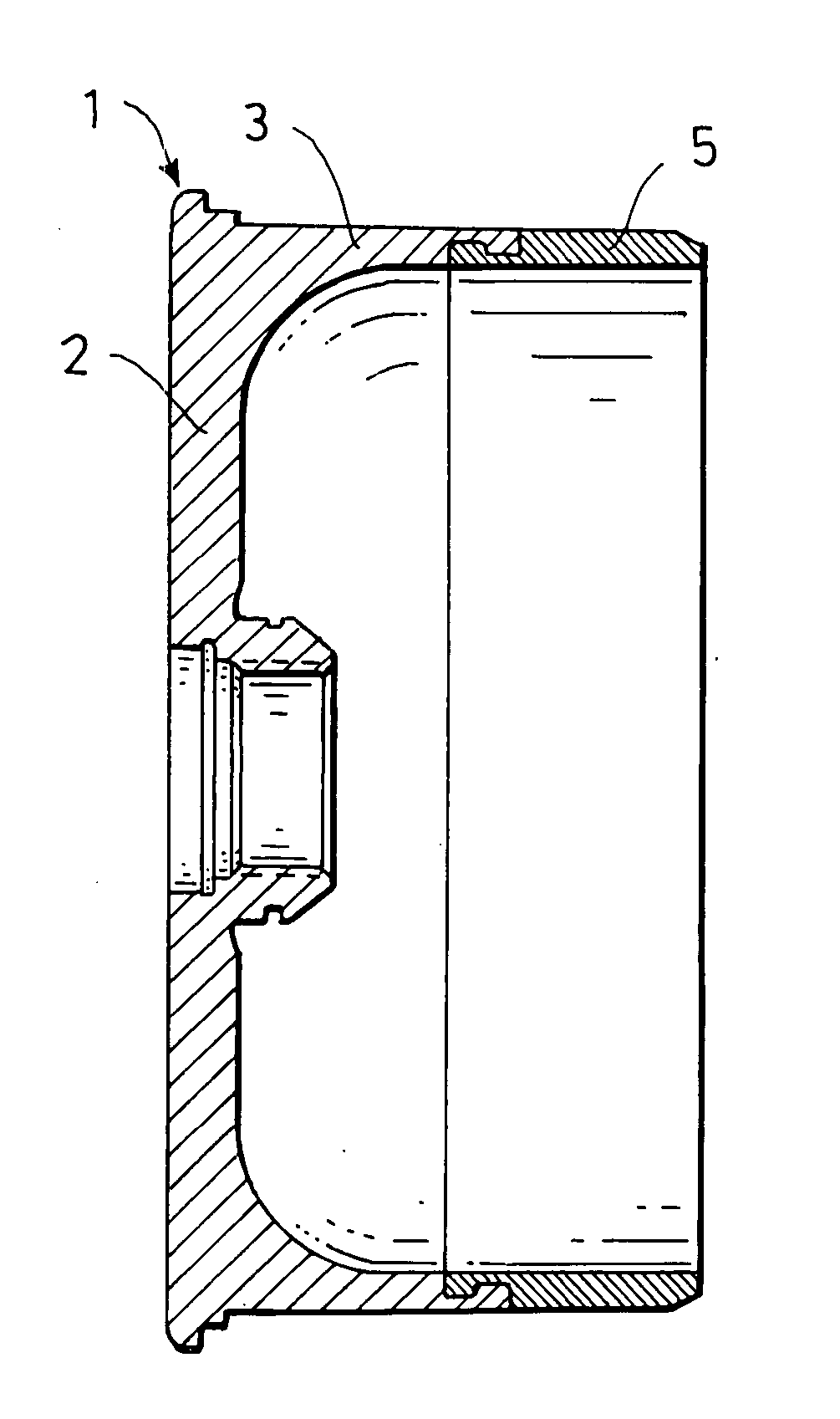

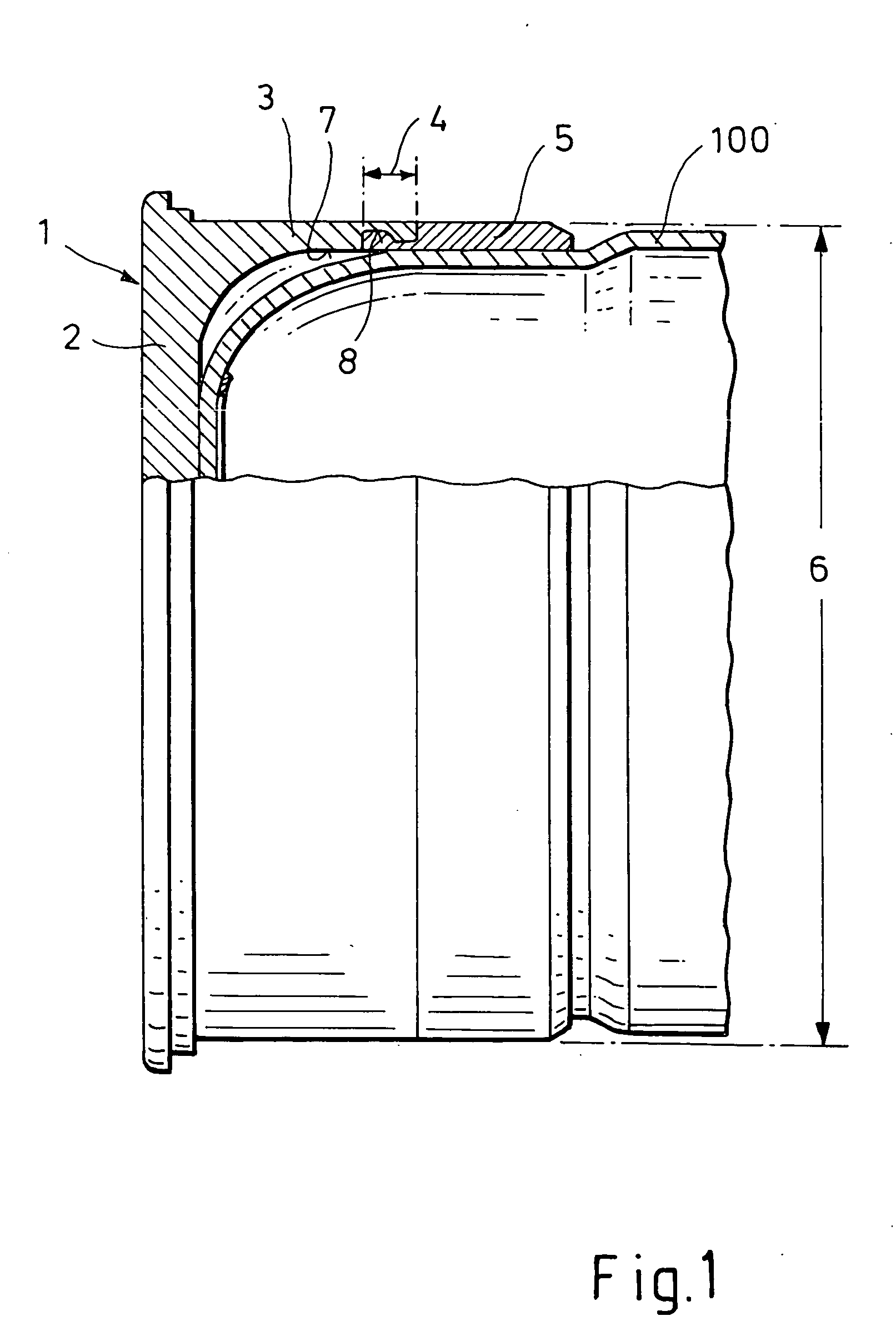

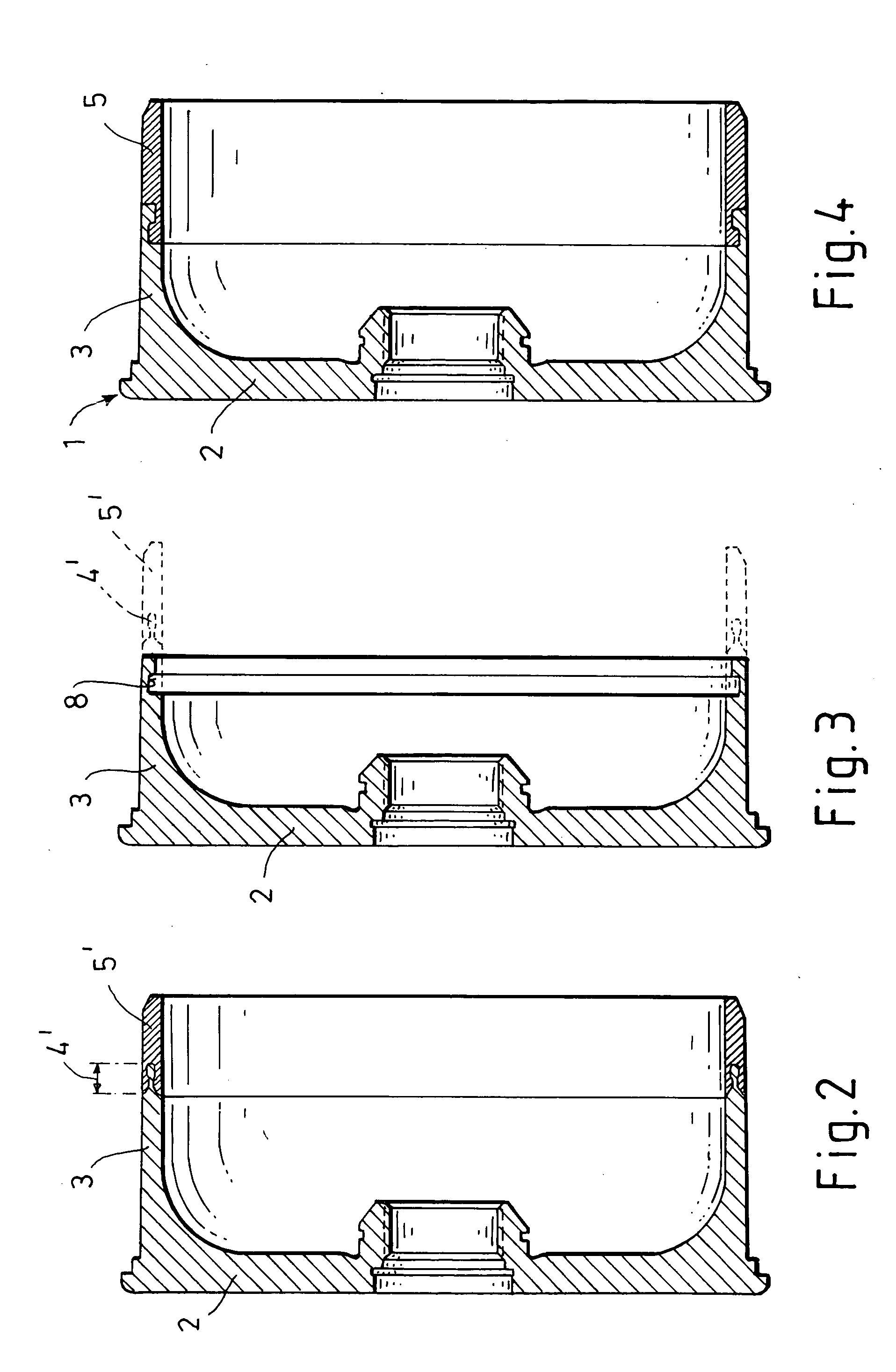

[0019]FIG. 1 shows an example of an embodiment of the invention. The reference 1 in FIG. 1 relates to the case bottom of a tank cartridge with combustible case jacket 100. The case bottom 1 comprises a bottom section 2 and a cylindrical case section 3 of steel. On the side facing away from the bottom section 2, the case section 3 is provided with a guide region 4 for guiding a ring-shaped obturation 5 of rubber that projects on the front and is connected to the case bottom 3.

[0020] According to the invention, the outside diameter 6 of the guide region 4 is selected such that following the loading of the respective cartridge, the guide region supports itself directly and peripherally on the loading chamber inside wall of the respective weapon (not shown herein), so that no plastic deformation can occur in the guide region 4 during the firing of a cartridge.

[0021] The internal surface 7 of the case section 3 is provided with an annular groove 8 in the guide region 4, wherein the obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com