Tube retaining device

a technology of retaining device and tube, which is applied in the direction of flexible containers, packaging, pliable tubular containers, etc., can solve the problems of not being as simple, inexpensive and beautifully functional in retaining tube, and achieve the effects of preventing backfilling, reducing cost and effort, and solving the problem of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

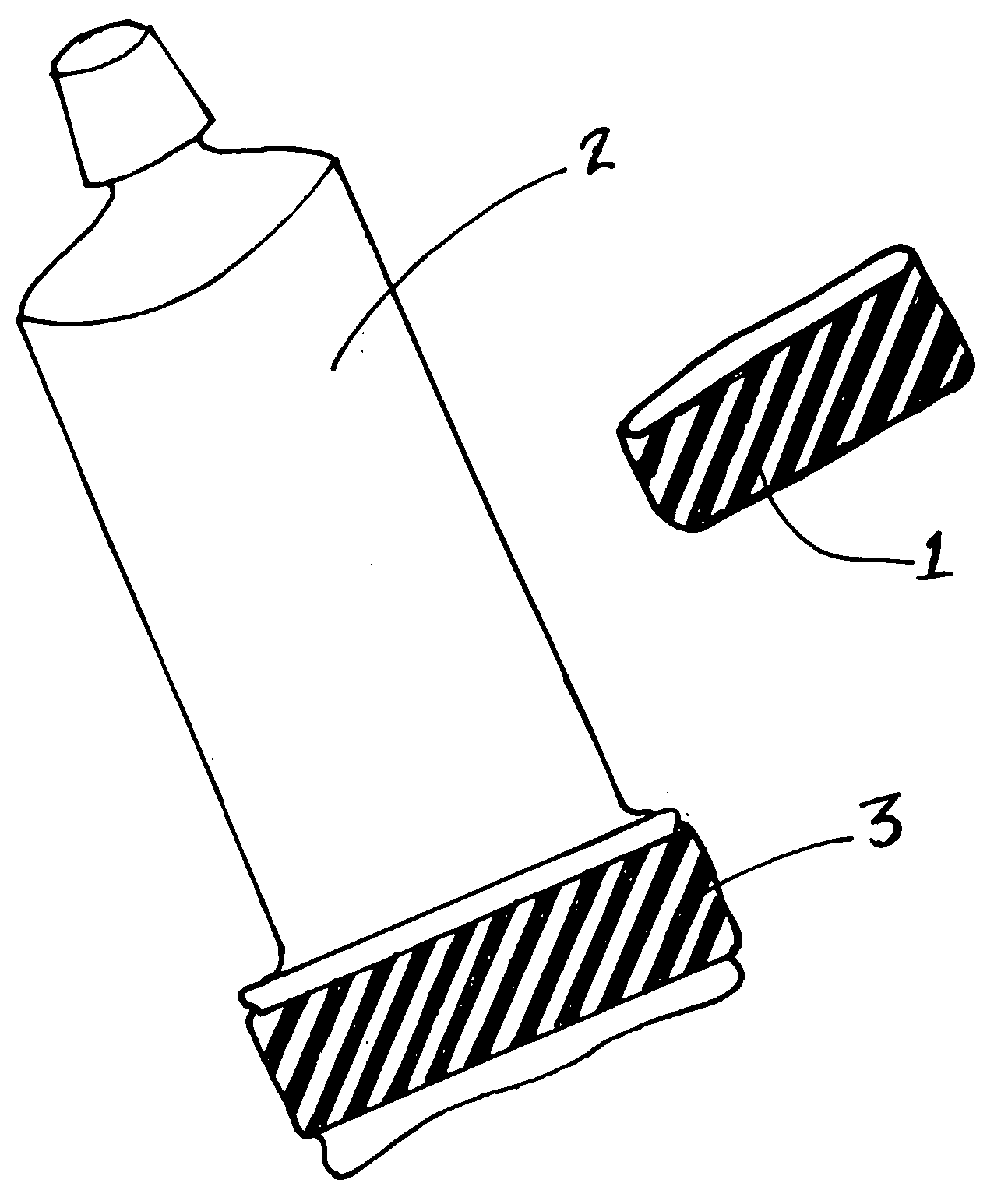

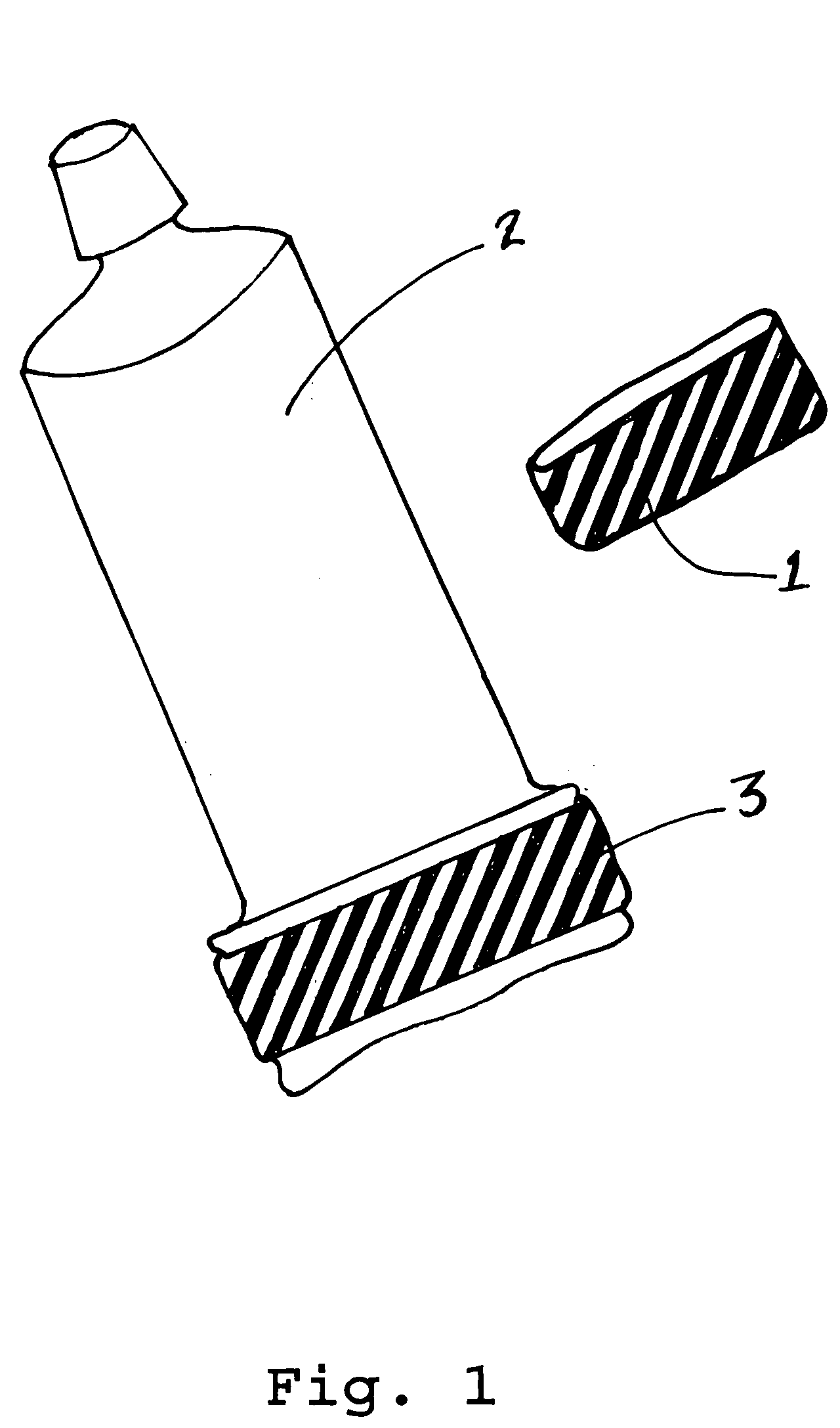

[0008] The Tube R taining Device is comprised of a stretchable / elastic-retractable; fabric-elastic, rubber elastic, or elastomeric material. This material is conjoined at the ends and forms a circular, oval, or flat (FIG. 1, 1) loop. These elastic band\loop Tube Retaining Devices are manufactured in different lengths, widths, thicknesses, and coefficients of elasticity. This component differential provides accommodation to various sizes of closed end collapsible or toothpaste type tubes (FIG. 1, 2). One of said elastic band / loop modalities is selected to conform to an individual tube size. It then, when stretched around the partially emptied and previously folded or rolled portion of a collapsible closed end tube such as a toothpaste tube, encircles and partially or entirely surrounds and holds compressed that end of the tube, (FIG. 1, 3). The surface of said elastic material is resistant to slippage on or about the tube. This loop is of such expandable resistance to, when stretched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com