Method for the production of high-concentration manganese mini-tablets for alloying aluminum baths and device for implementing said method

a technology of high-concentration manganese and aluminum bath, which is applied in the direction of presses, manufacturing tools, shaping presses, etc., can solve the problems of molten metal, no materials on the market that contain a percentage above 85% mn, and no compact mn materials have appeared on the market, so as to achieve high mn concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

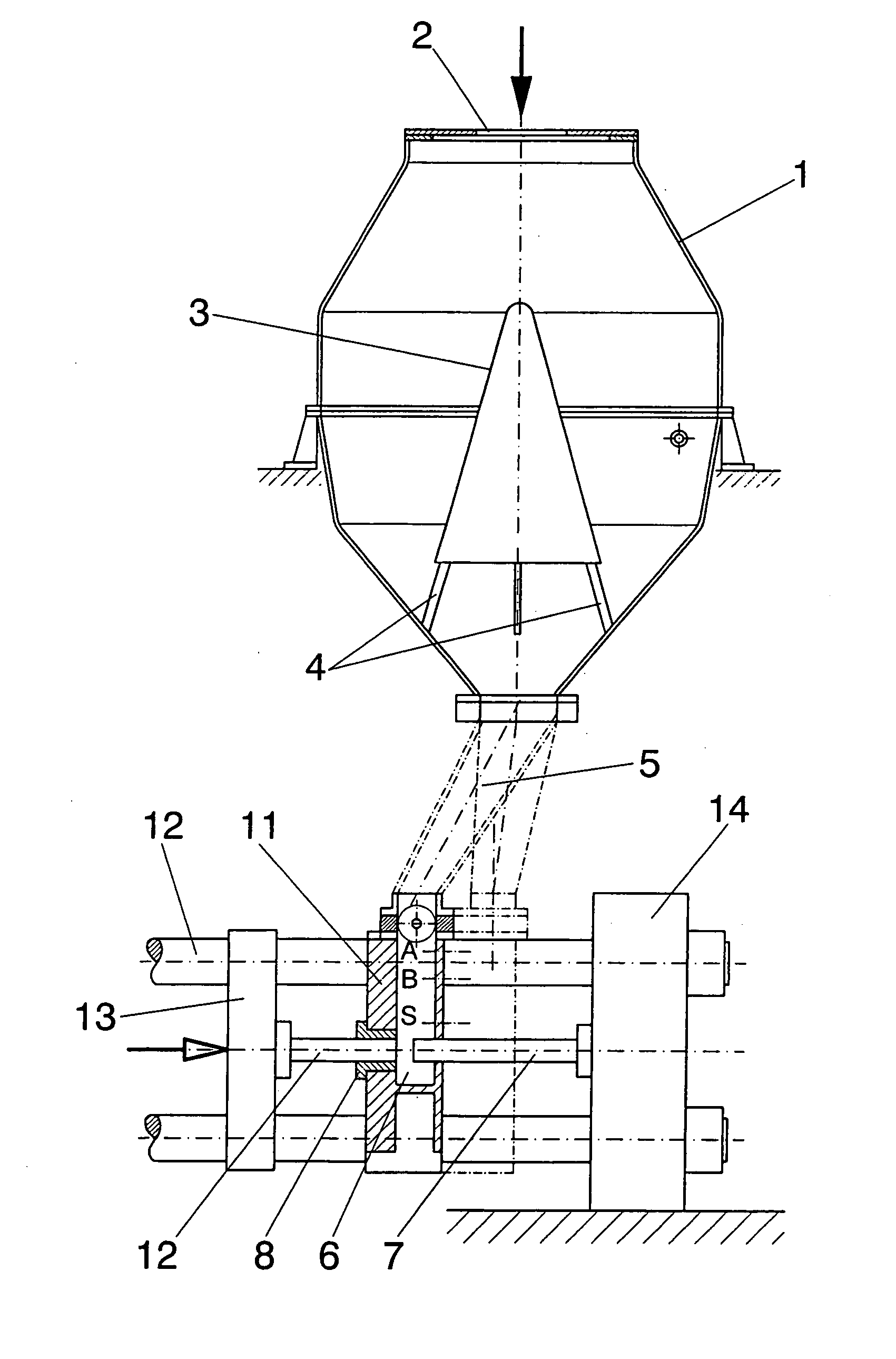

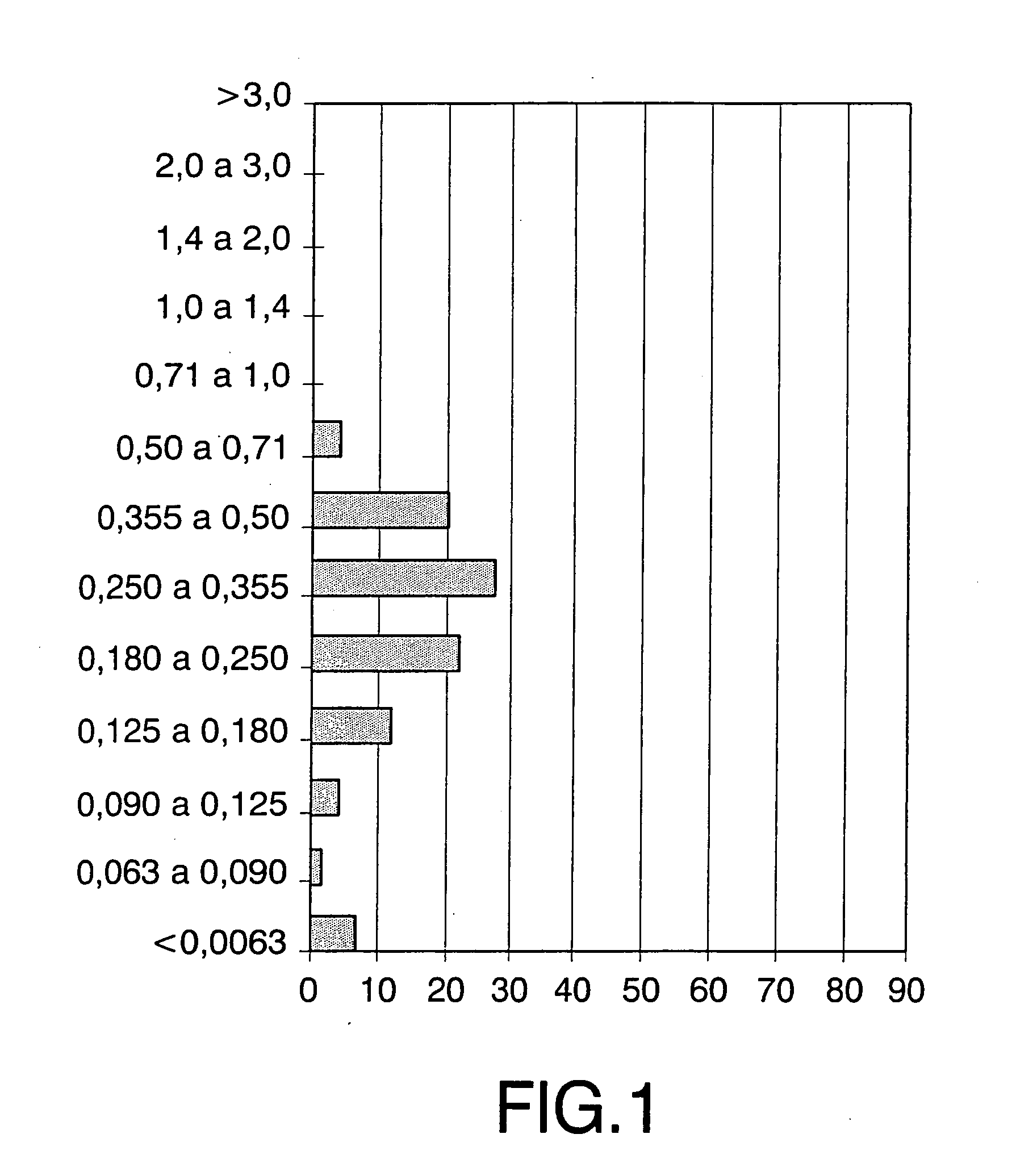

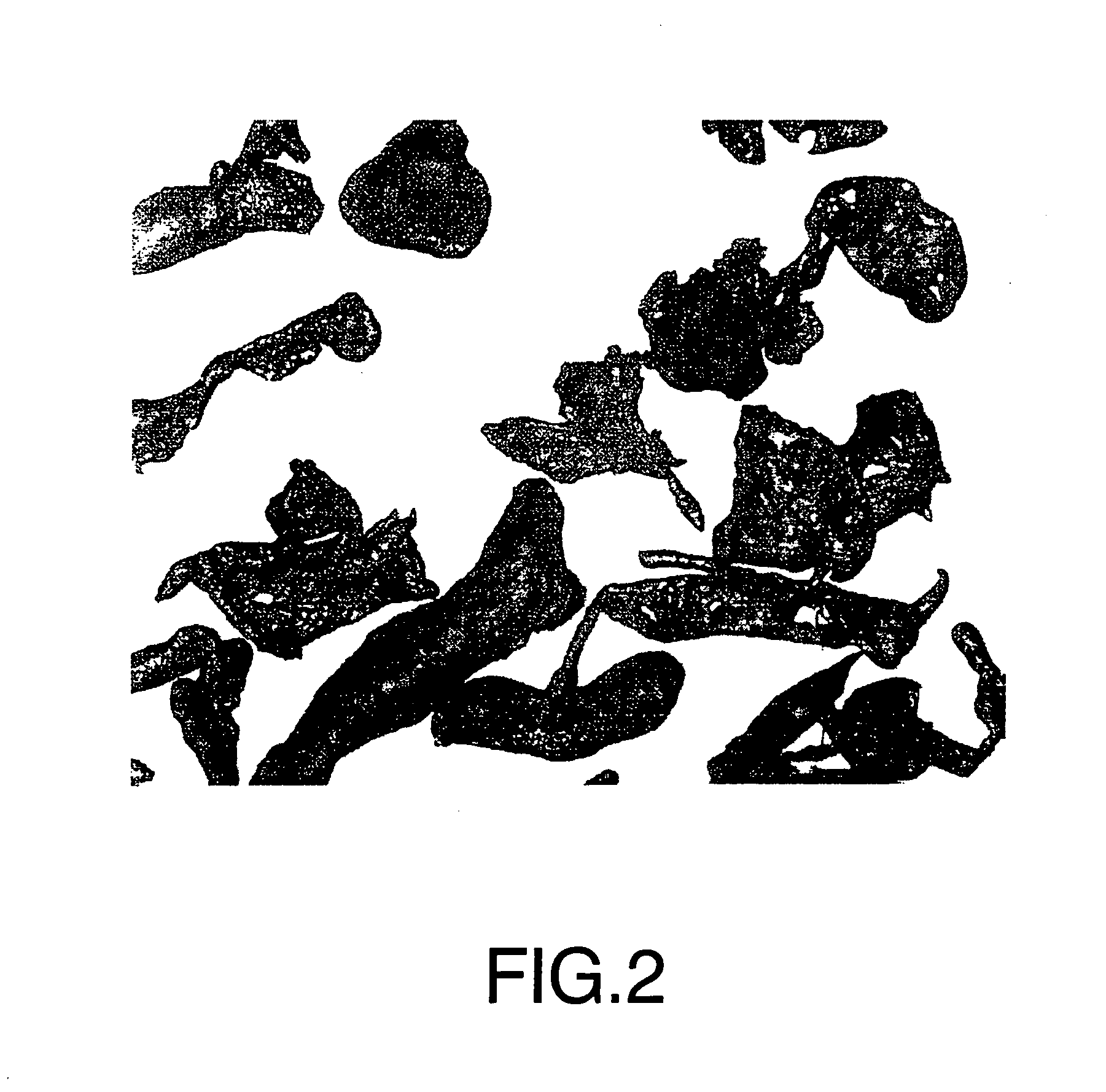

[0013] The procedure that is advocated offers a solution to the problems and difficulties mentioned in the previous section, for which purpose it is specified that, starting from the two components used, which have to be mixed, namely Mn and Al, Mn minitablets with a concentration of more than 90% should be compacted by using Mn produced by electrolysis and ground from flakes of Mn of a chemical purity of 99.7% or more, which is subjected to a screening process with a sieve with a mesh of less than 450 microns; the special feature of the Mn grinding process is that it is controlled so that the content of fine Mn powder, with a size of less than 100 microns, should not be more than 15%, as above this proportion the compacting of Mn minitablets cannot be assured with over 90% Mn in their composition.

[0014] The procedure also includes the fact that the most suitable Al for successfully compacting Mn minitablets is atomized powder, which is produced by mechanical processes, with contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com