Glass fiber metal matrix composites

a technology of metal matrix composites and glass fibers, applied in the field of fiber reinforced metal matrix composites, can solve the problem of complex materials and high cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

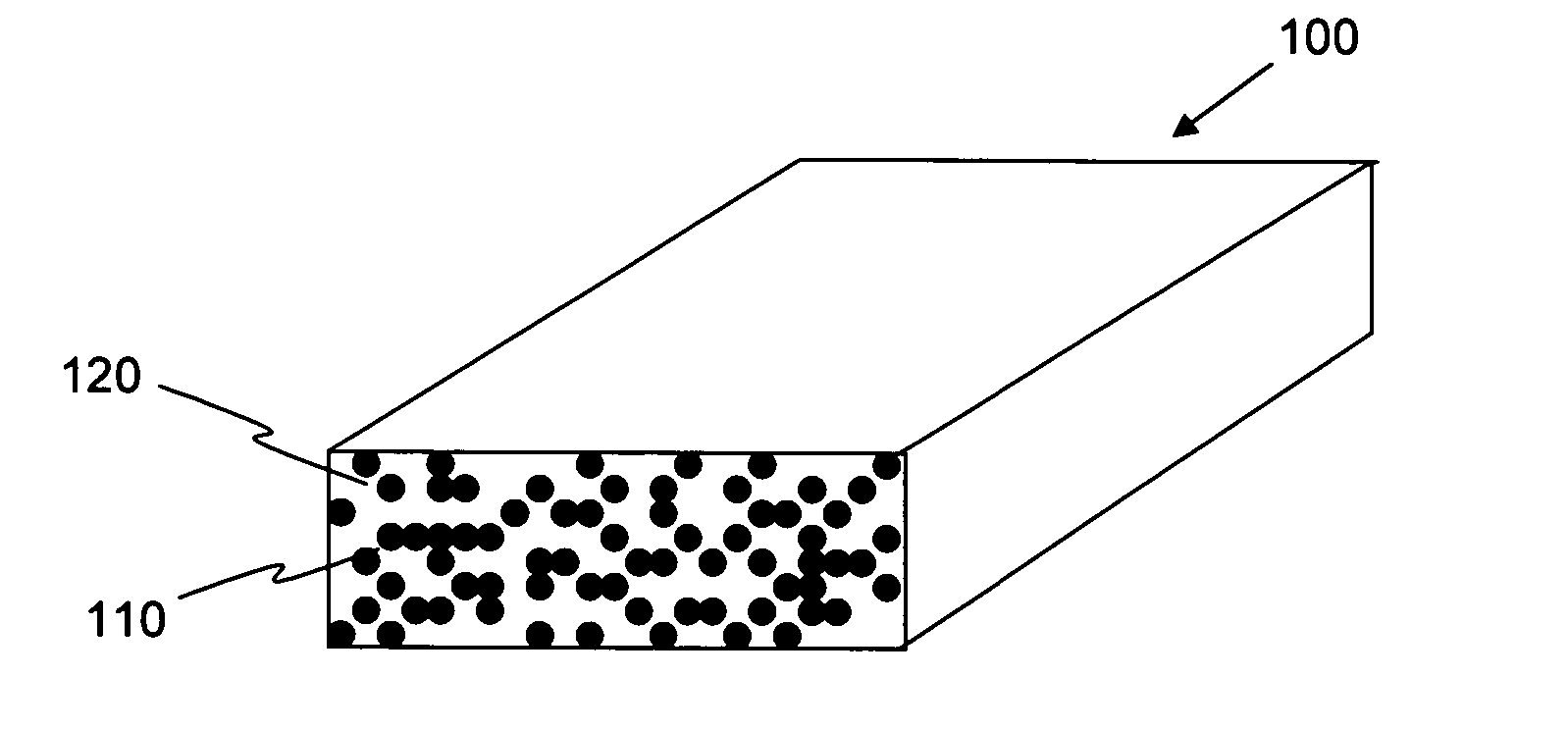

Image

Examples

example

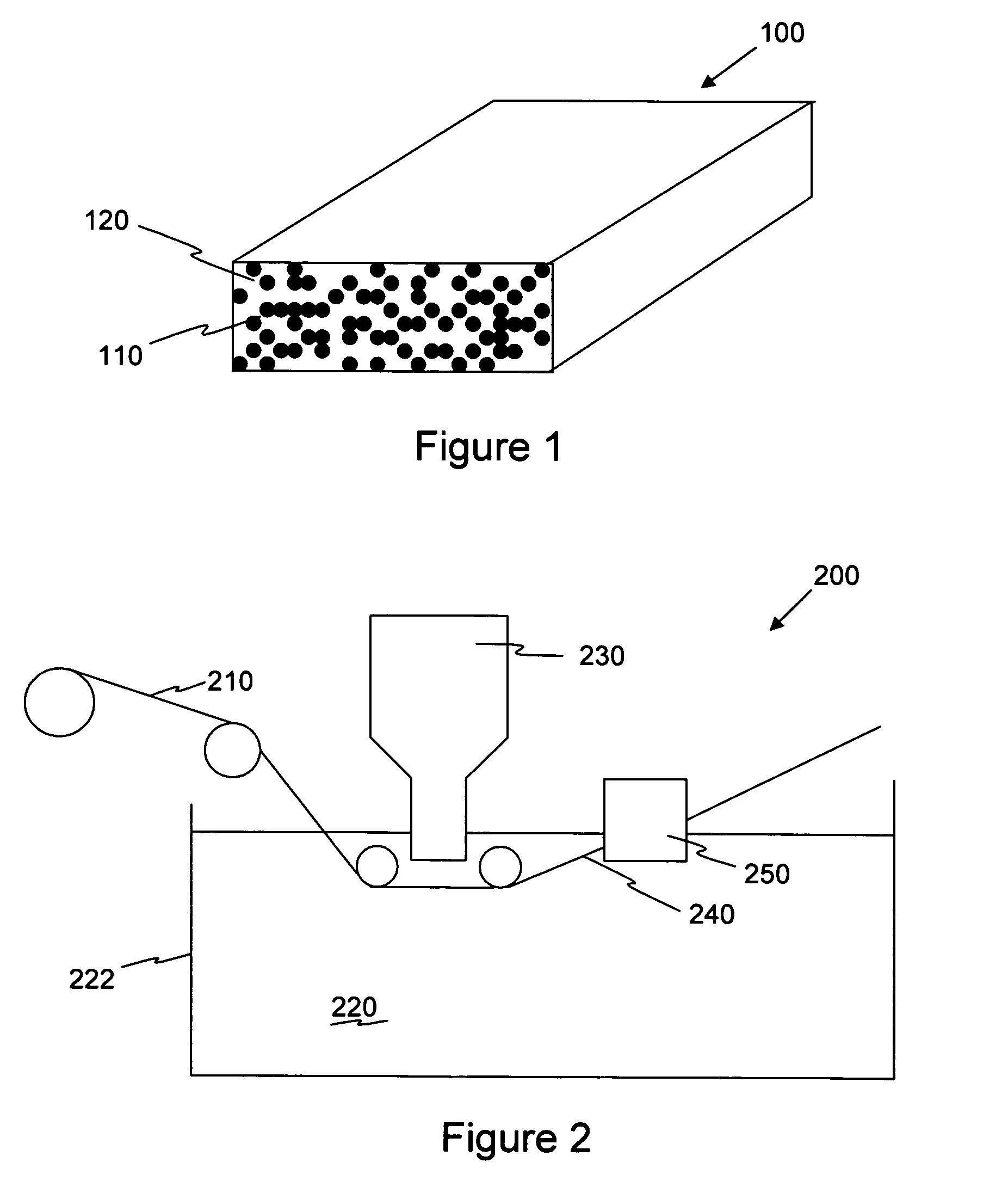

[0018] High strength S-2 glass fibers listed in Table I were infiltrated with a metal matrix by passing the glass fibers into an aluminum bath, passing the fibers near an ultrasonic waveguide, and removing the infiltrated fibers from the aluminum bath. The glass fibers were supplied from Advanced Glassfiber Yarns.

TABLE IGlass FibersLoss onFilamentIgnition (LOI)YieldFilamentDiameterID(%)(yds / lb)TexDenierCount(μm)721B-AA-7500.657506605940173014365-225-TRL2880.72252200 19,800 173023933-AA-3750.233751325 11,880 16,320 9933-AA-7500.23750660594081609463-AA-7501.0750660594081609449-AA-2500.652501980 17820 24,480 9

[0019] A pure aluminum bath and an aluminum with 12% silicon bath were used in the process. The aluminum bath temperature was held constant at 1350° C. The ultrasonic probe positioned was varied between 0.125 and 0.250 inches from the glass fibers. The ultrasonic amplitude was varied between settings of 30 and 60 and the processing speed was varied between 36 inches per minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com