Setting for diamonds or diamond shaped stones

a technology of diamonds and diamonds, applied in the field of diamond or diamond shaped stones, can solve the problems of increasing risk, oblique angle of prongs not matching the most common and preferred culet angle, and undesirable appearance of empty space, and achieve the effect of quick setting diamonds and easy use by jewelers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

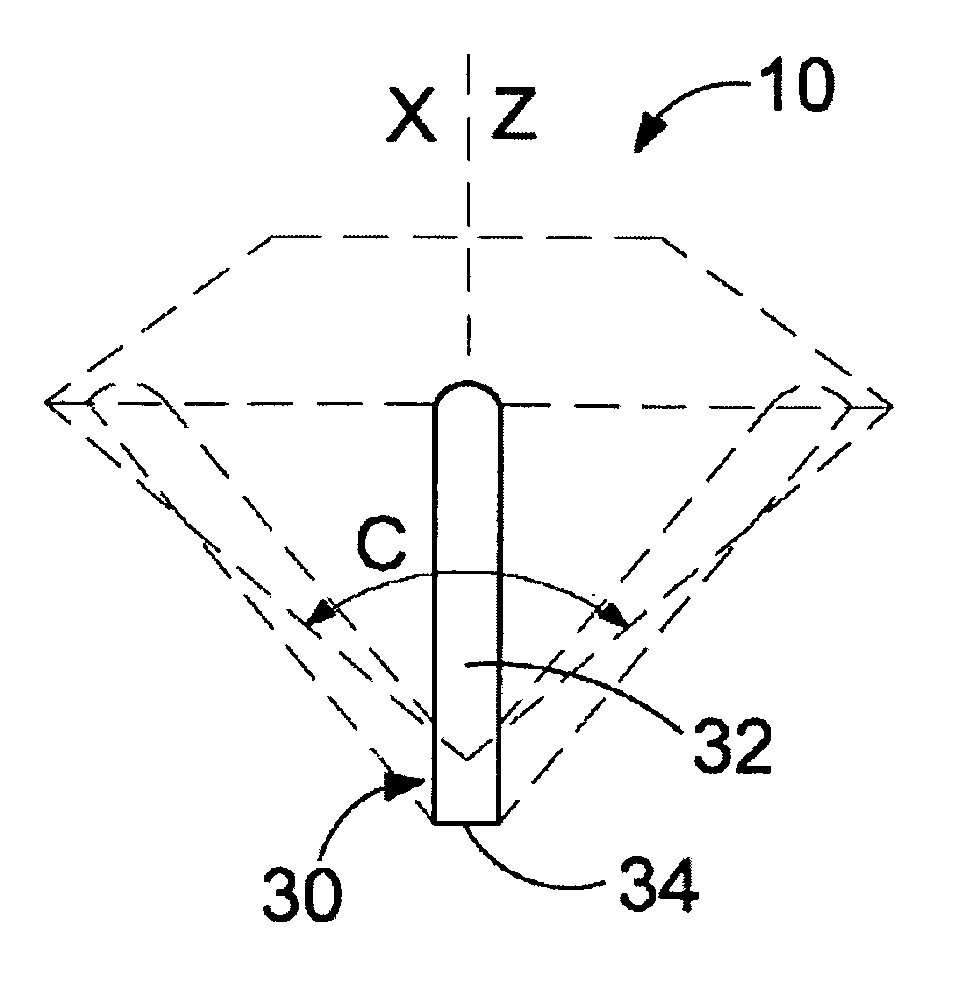

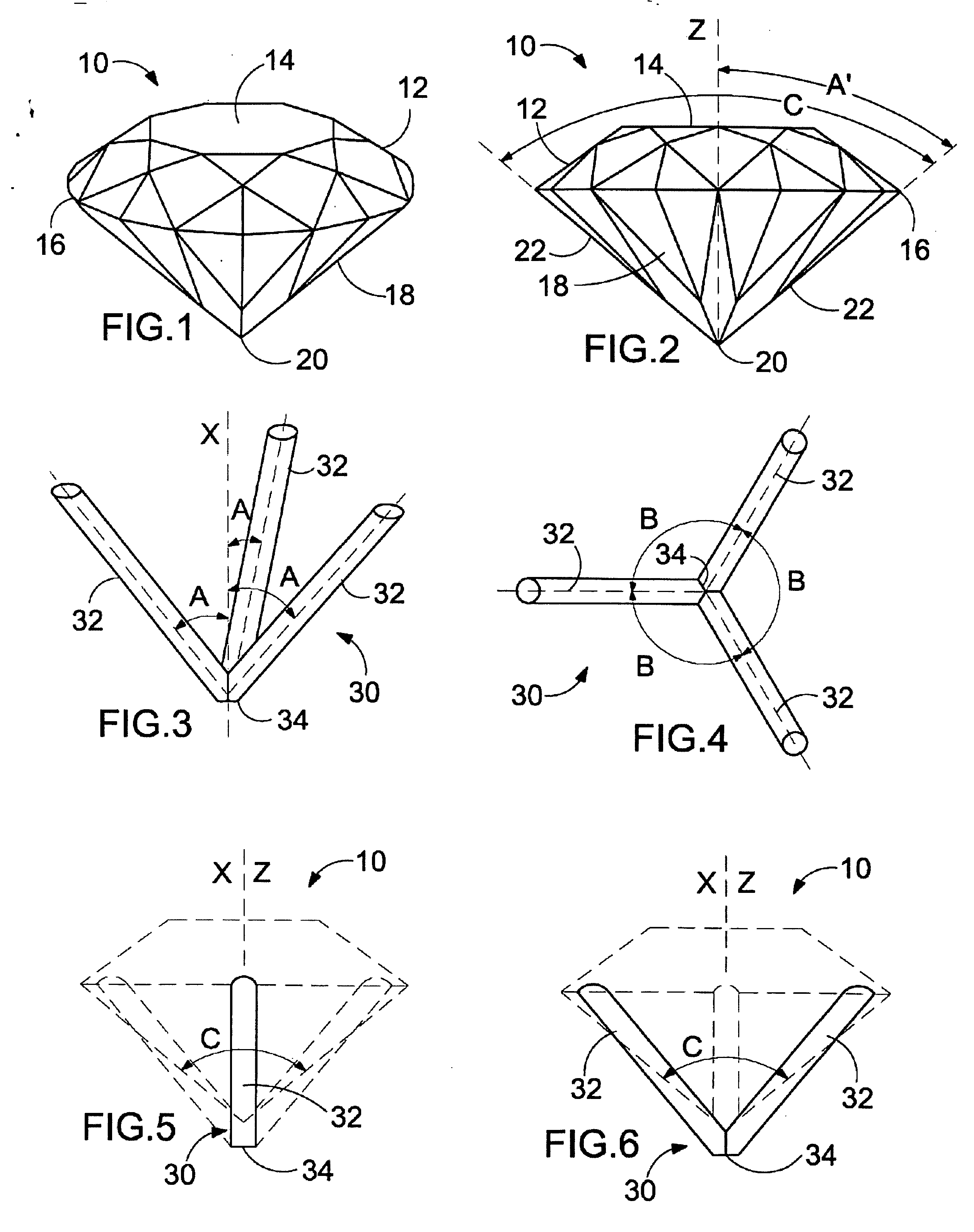

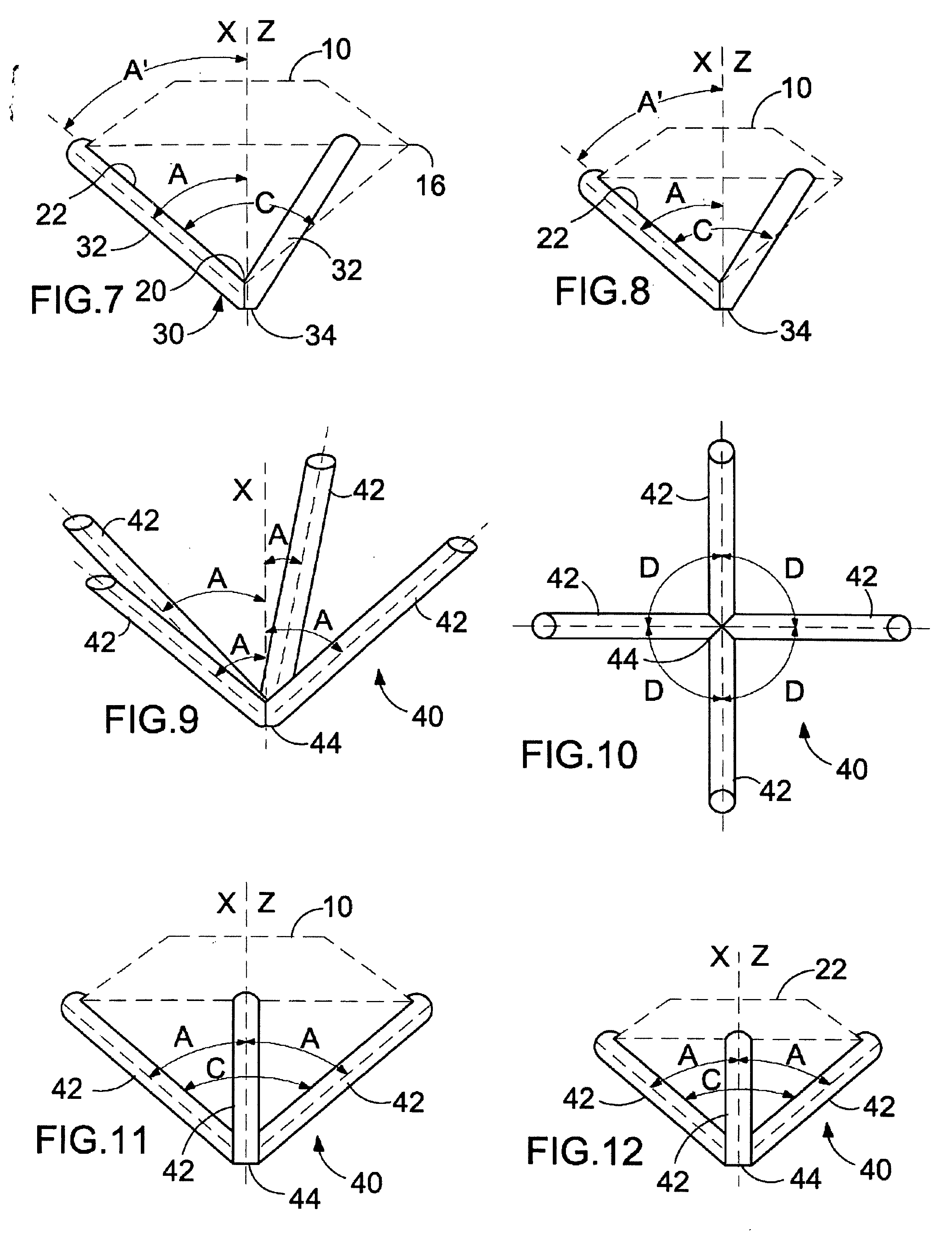

[0039] Referring to FIGS. 3 and 4, one of the preferred embodiments of the present invention setting for diamonds or diamond shaped stones is shown and generally referred to by the numeral 30. In the following descriptions, the word “diamond(s)” will be used to indicate both diamond(s) and diamond shaped stone(s).

[0040] The setting 30 has three prongs 32 generally made of metal or other similar materials. The prongs 32 are joined at their bottom ends to form bottom joint 34 which serves as the base of the setting 30. The prongs 32 extend upwardly and outwardly from the bottom joint 34, and are disposed spaced apart symmetrically about a symmetric axis X of the setting 30, i.e., the angle A between each prong 32 and the axis X is the same, and the angle B between any two adjacent prongs 32 is also the same for all three prongs 32.

[0041] One of the most important novel and unique features of the present invention setting 30 is the oblique angle A of its prongs 32. As discussed earli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| culet angle | aaaaa | aaaaa |

| oblique angles | aaaaa | aaaaa |

| oblique angles | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com