Advance working or mining machine

a technology of advanced working or mining machines, applied in cutting machines, driving means, anchoring bolts, etc., to achieve the effect of avoiding any limitation of the maneuverability of advance working machines, stable operating platforms, and enhancing the protection of operating personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

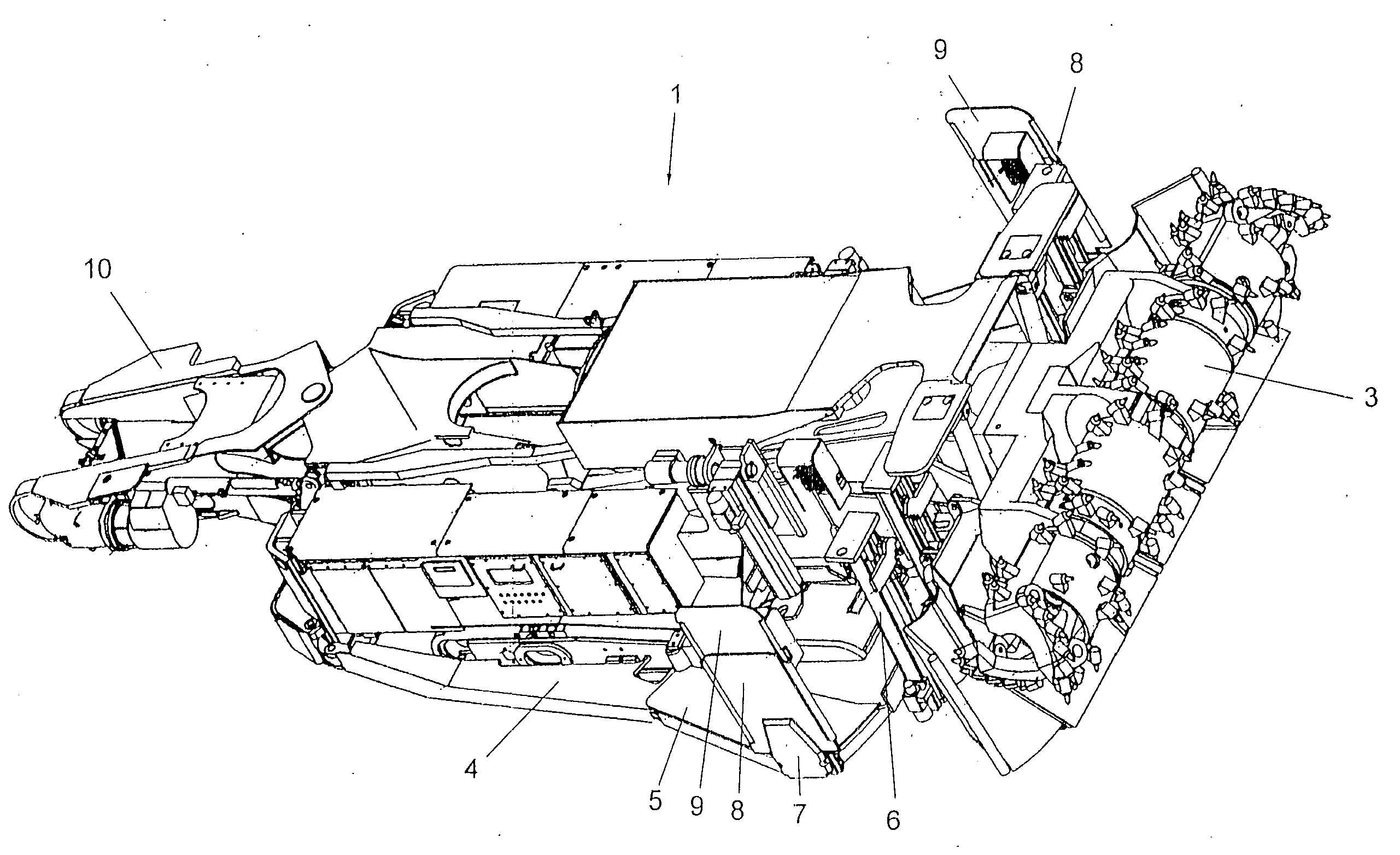

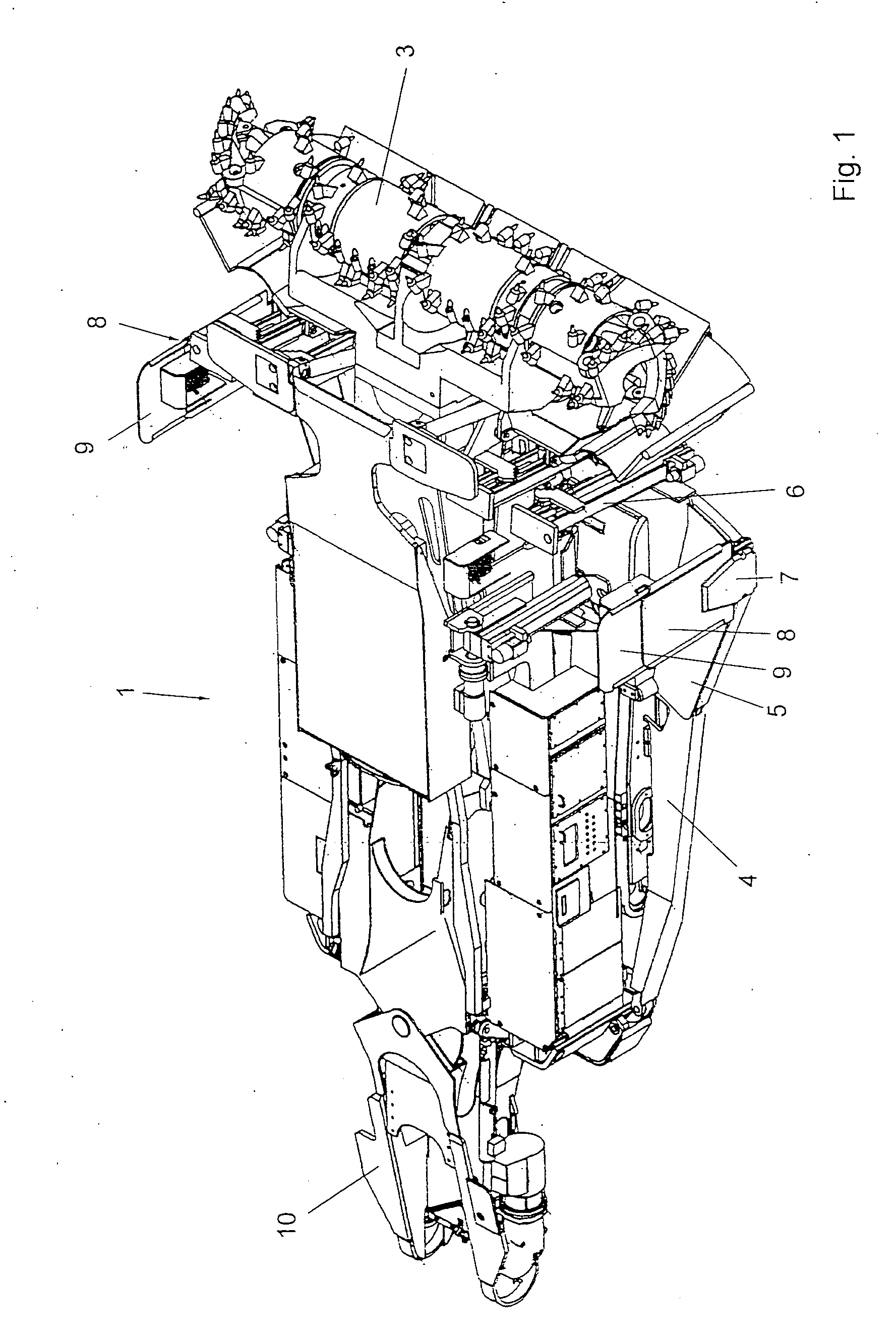

[0018]FIG. 1 depicts an advance working machine 1 on whose front end facing the work surface a cutting cylinder 3 is arranged to be pivotable in the vertical direction. The advance working machine 1 comprises lateral operating platforms 4 and pivotally hinged platforms 5 accordingly enlarging the operating range in the vicinity of roof bolt drilling and setting apparatus schematically indicated by 6. The lateral partial region of the pivotable platform 5, which is adjustable at the side wall, carries runners 7 and a shield-like protection wall 8 telescopically designed in the vertical direction by means of extractable parts 9 so as to likewise ensure a lateral protection against collapsing rock in the region of the operating platform 5.

[0019] On the rear end of the advance working machine 1, appropriate bearing sites for a conveying means are to be seen on the machine frame 10.

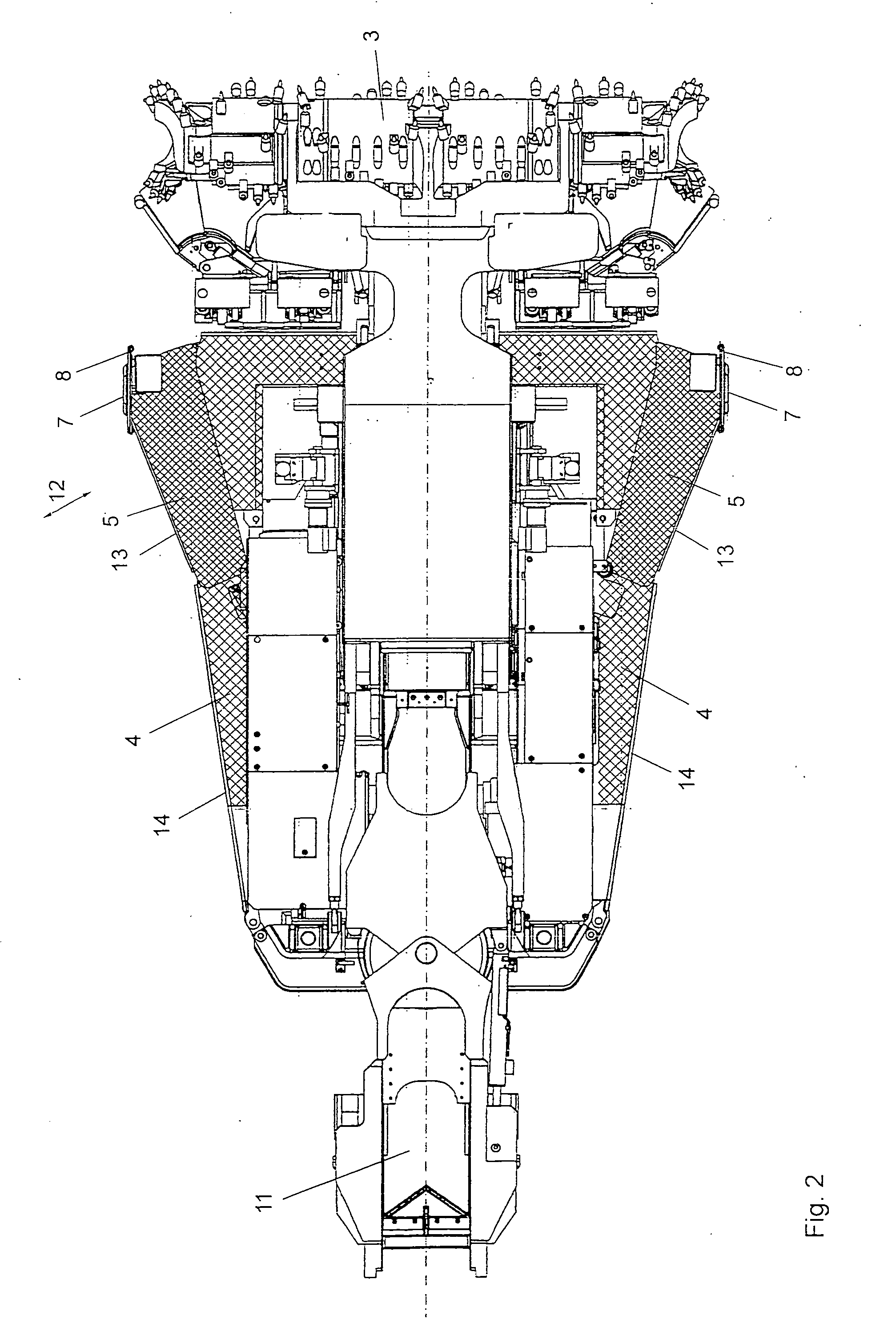

[0020] In the illustration according to FIG. 2, the operating platforms 5 are in a laterally pivoted-out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com