Transport container for wind turbine blades

a technology for transporting containers and wind turbine blades, which is applied in the direction of containers, special packaging, packaged goods types, etc., can solve the problems of increasing the manufacturing cost of containers, causing unnecessary weight and space when transporting smaller blades, and exacerbated problems, so as to reduce the height of containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

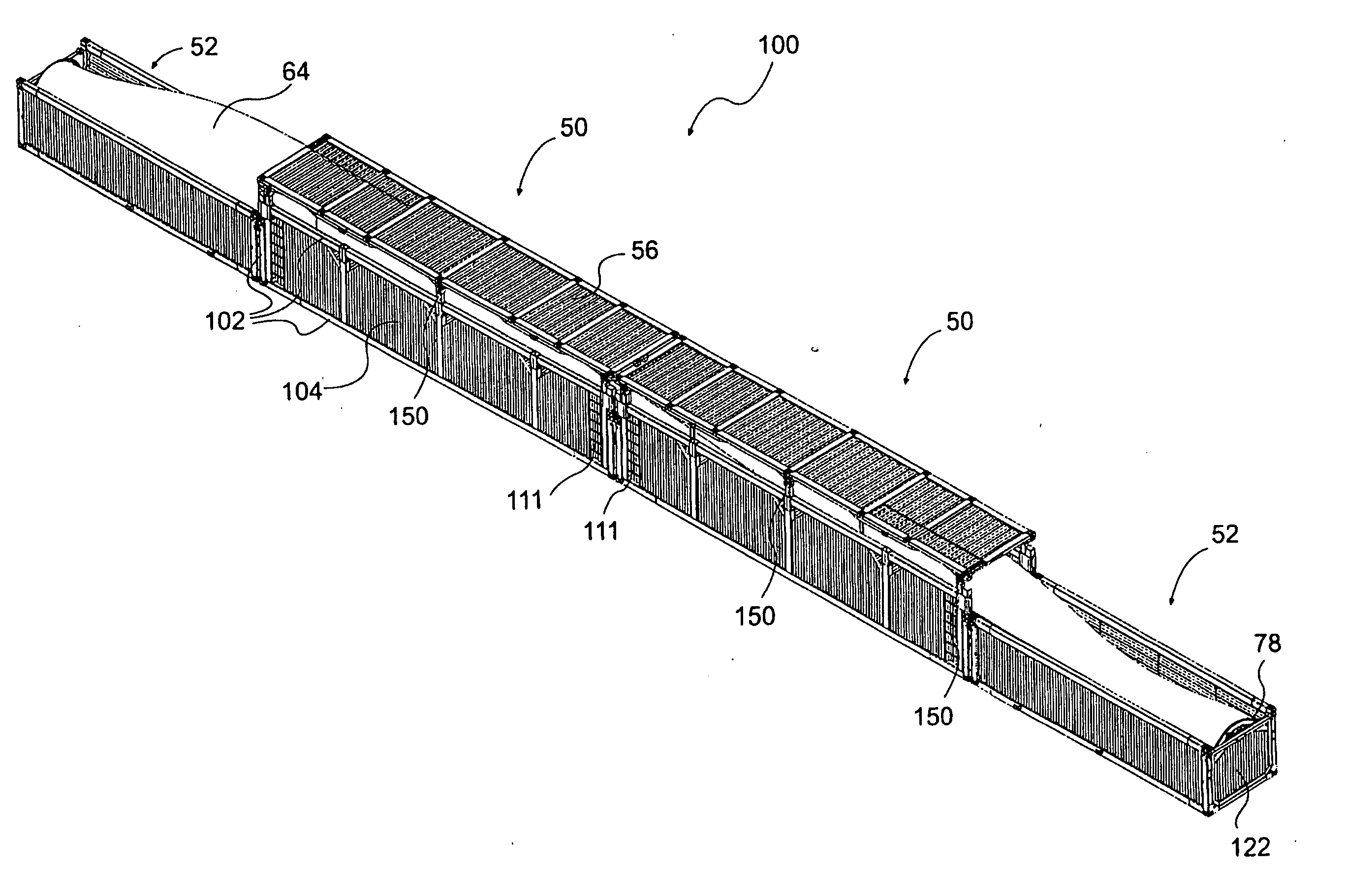

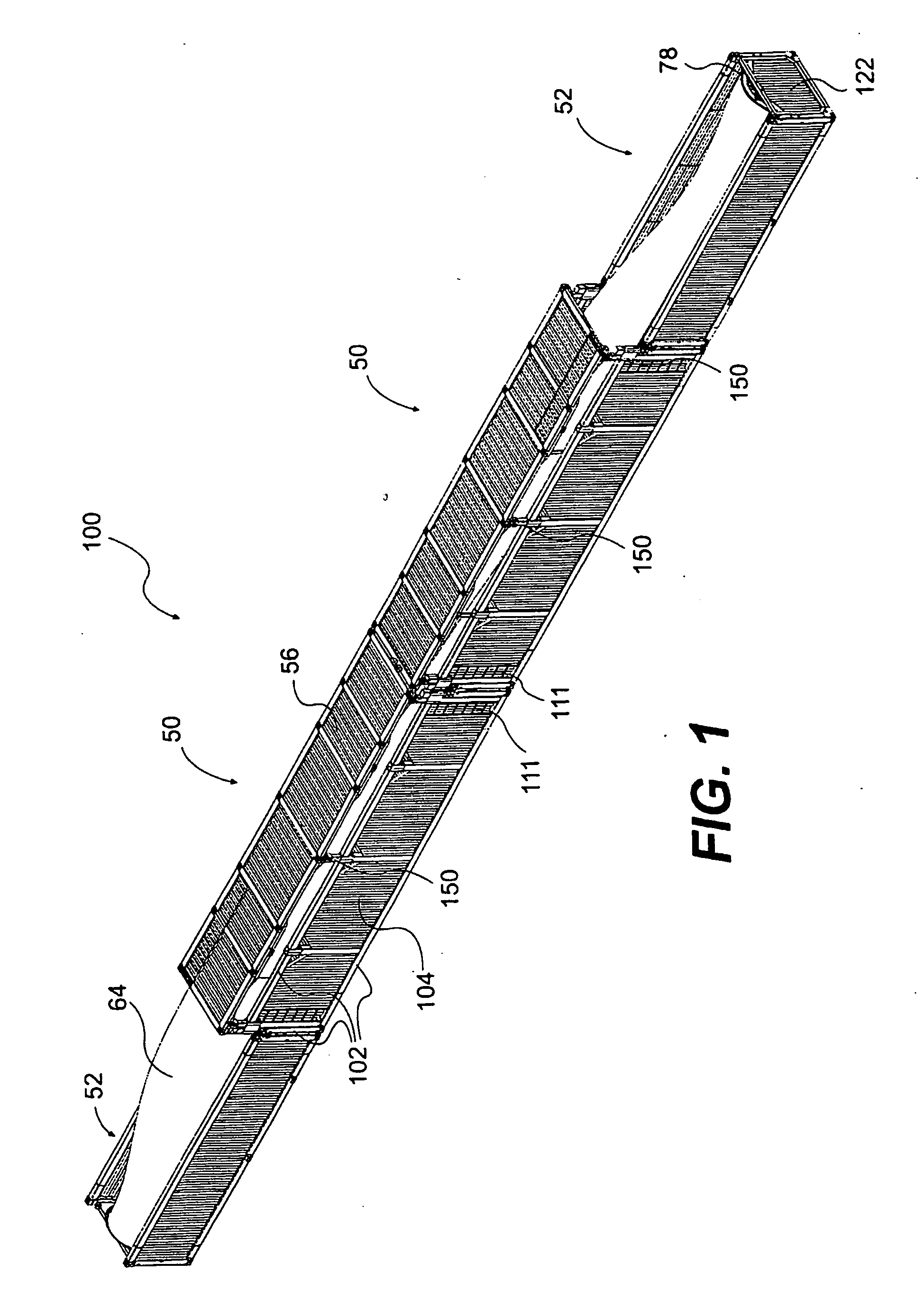

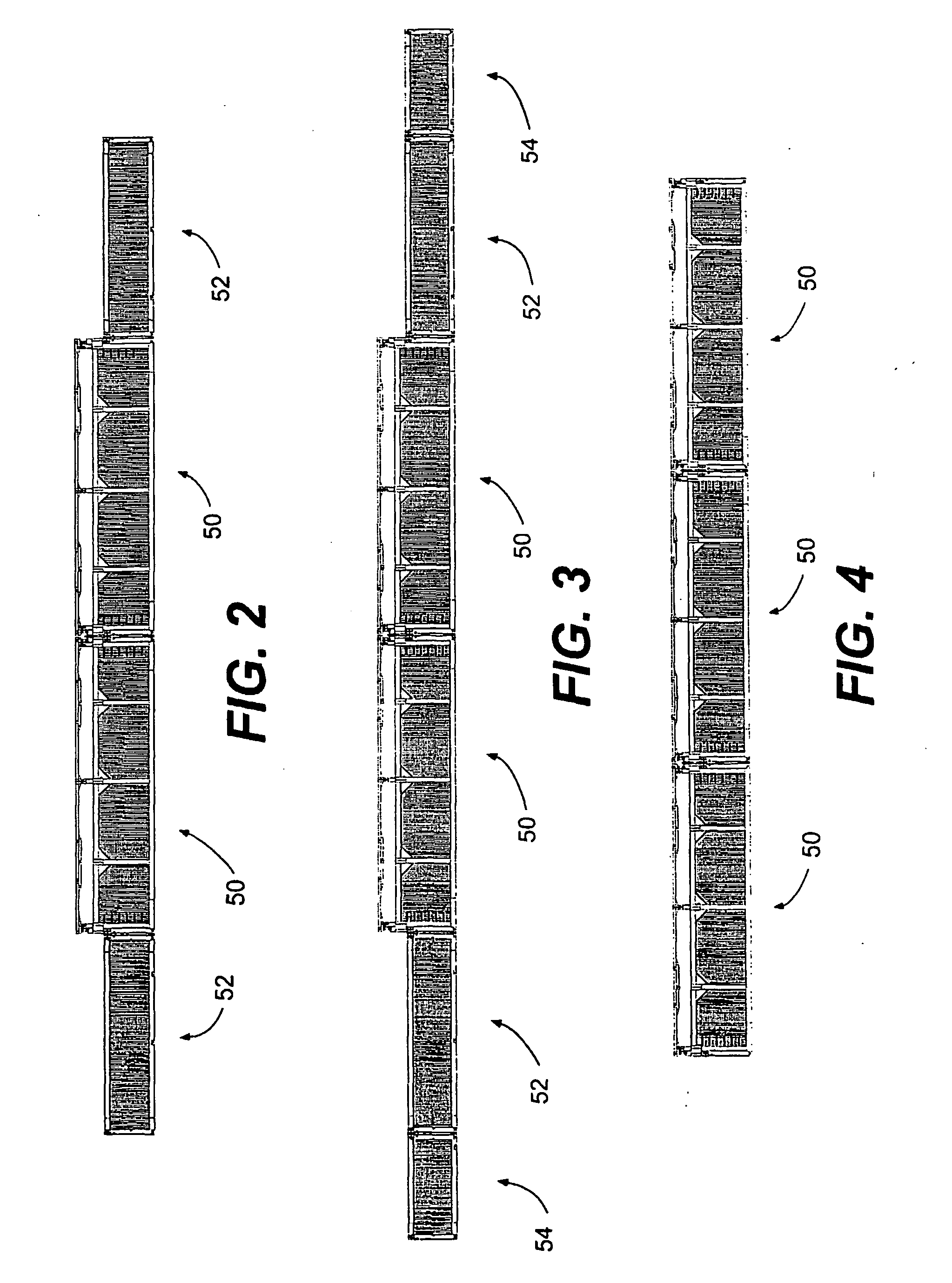

[0039] As shown in FIG. 1, a container system for transporting wind turbine blades can include various different modules 50, 52 connected together to form a large container 100. FIG. 1 shows a container 100 carrying two wind turbine blades 64, the root portions of each of the wind turbine blades being connected to a respective outer most end portion of container 100. Alternatively, container 100 could accommodate a single turbine blade 64. The container 100 can include at least one standard module 50 and can be extendable in length by attaching extension modules 52 (and / or modules 54, shown in FIG. 3) depending upon the size and shape of the wind turbine blade 64 to be accommodated. In other words, larger extension modules 52 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com