Moist towelette packaging

a towelette and packaging technology, applied in the direction of instruments, apparatus for dispensing discrete objects, de-stacking objects, etc., can solve the problems of insufficient packaging with dispensing mechanisms, inability to carry, and inability to carry, so as to reduce product fallbacks and mitigate the effect of product fallbacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

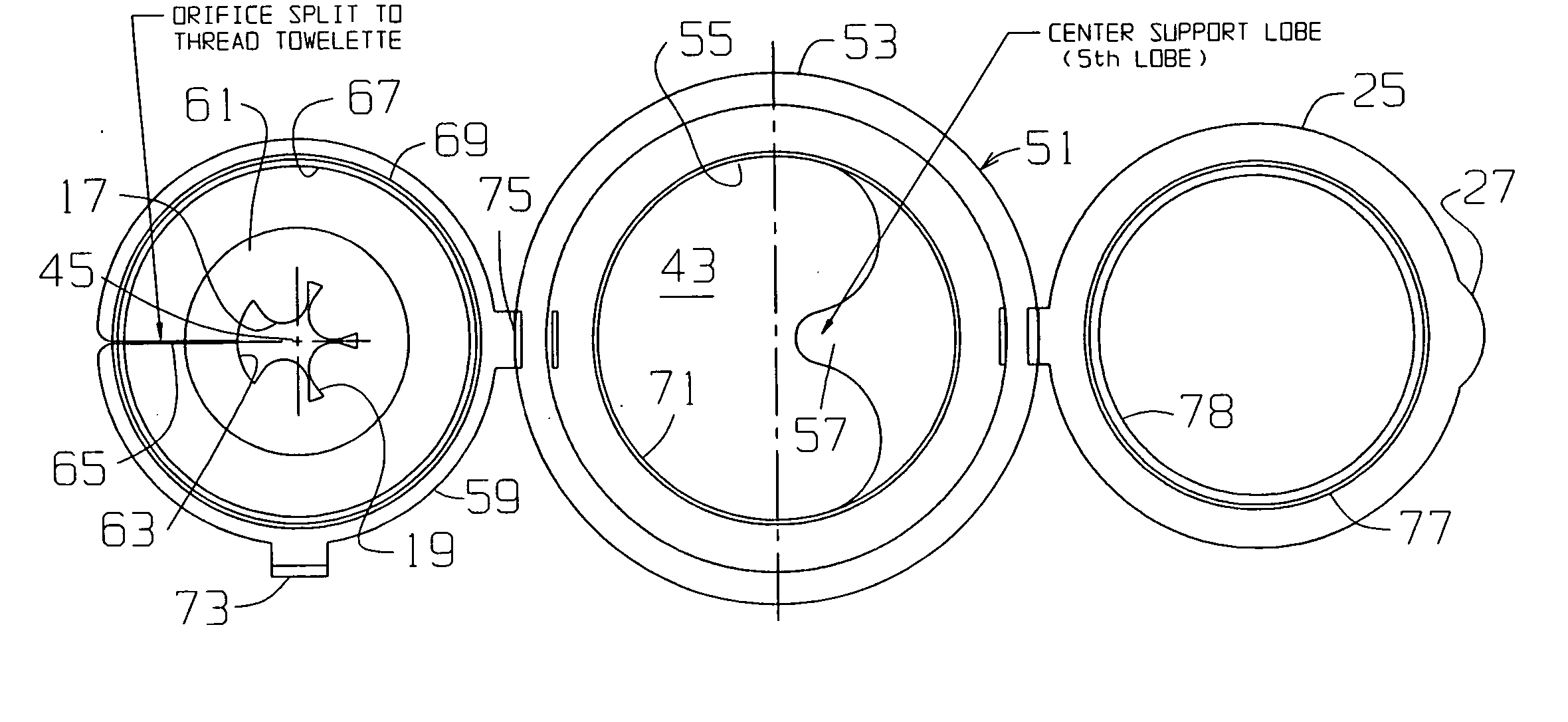

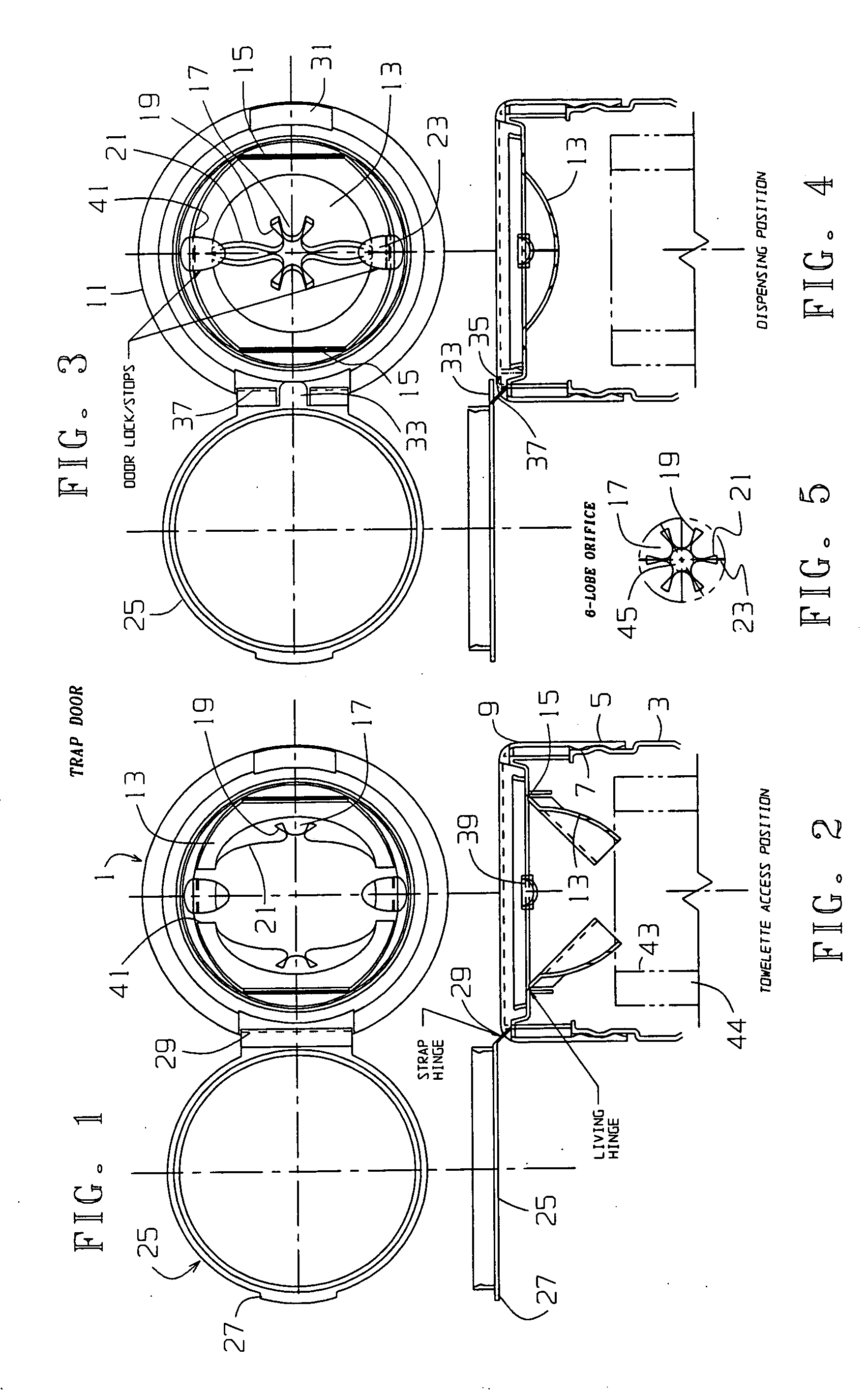

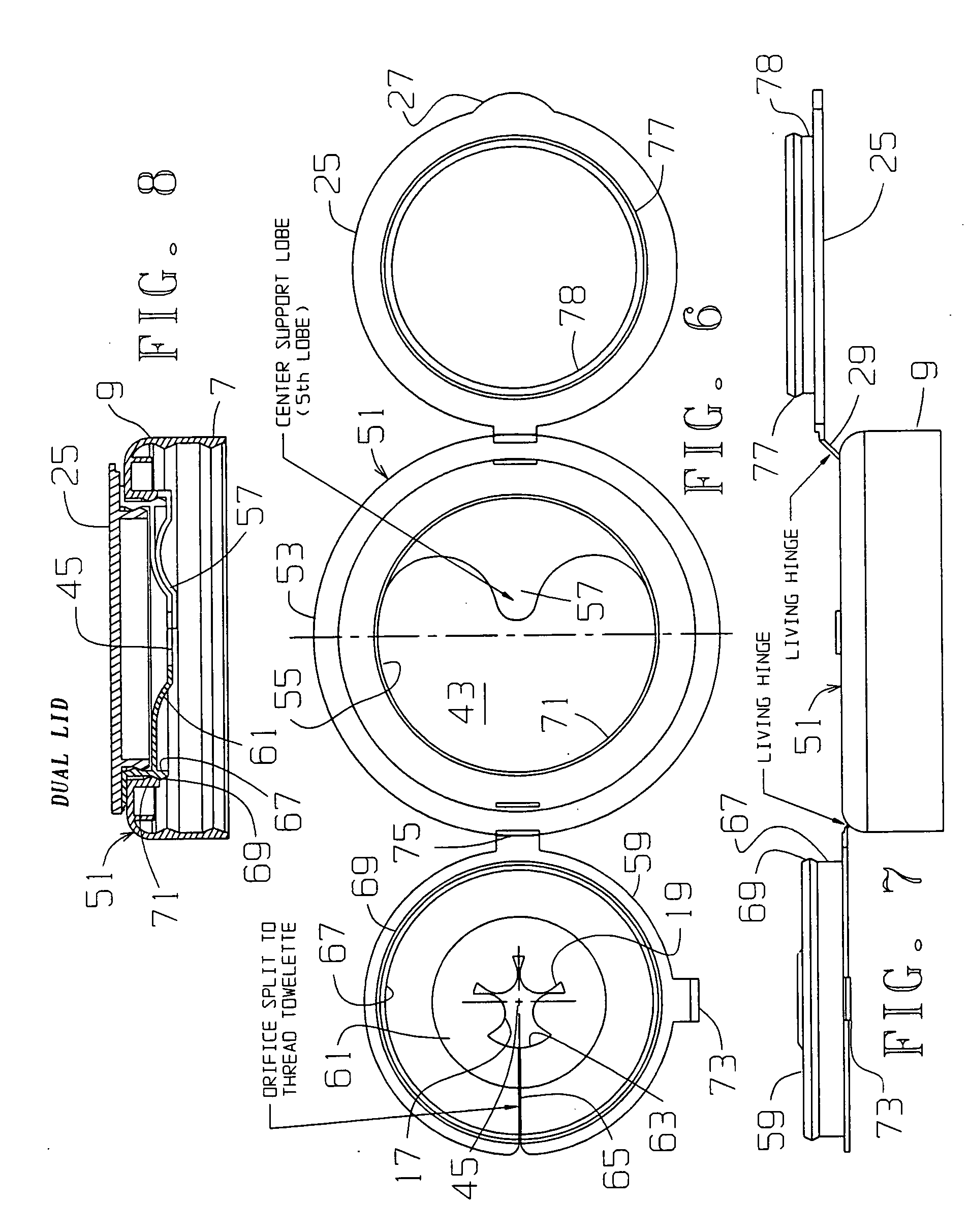

[0038] Referring to FIGS. 1-4, a trap door embodiment of the invention is generally referred to by the numeral 1. A container 3 has an open upper end 5 that is configured to receive a complementary lower end 7 of the cylindrical wall 9 of the dispenser 1. The dispensing top 11 has two mirror-imaged portions 13 pivoted on living hinges 15. Each half 13 has a dish shape with product-engaging lobes 17 formed between generally radially extending recesses 19. Elongated recesses 21 are formed along the parting line 23 of the two dish-shaped halves 13. A cover 25 with a lifting tab 27 is joined with the top about a living hinge 29. The tab 27 lies within a recess 31 when closed.

[0039] In one embodiment, an inward-extending tab 33 cooperates with a rim 35 on the top of the container and extends between two living hinges 37 to assist in holding the cover 25 fully opened or fully closed. Door lock stops 39 extend inward from the central opening 41 to prevent upward travel of the dish-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com