Pipe coupling having wedge shaped keys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

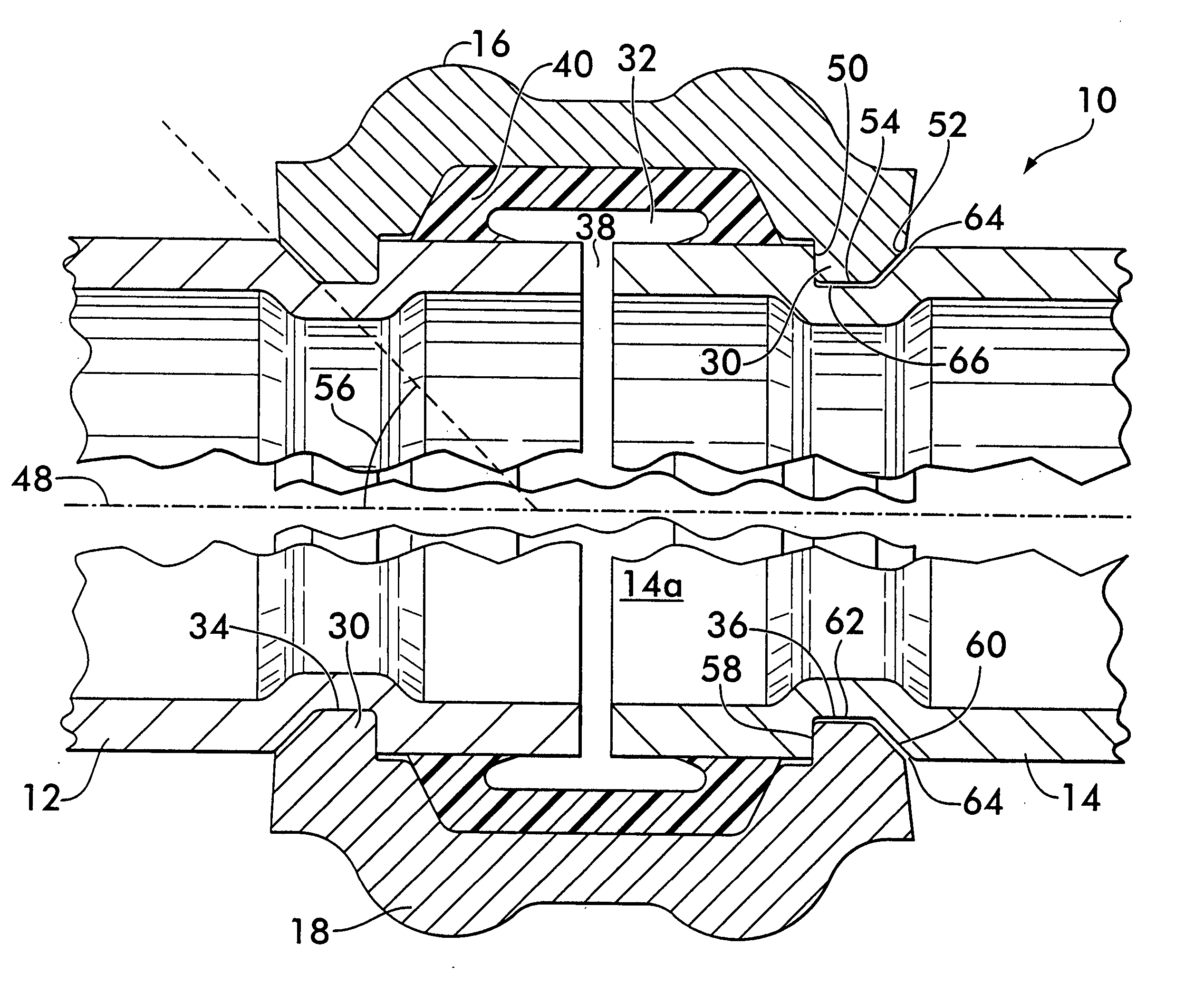

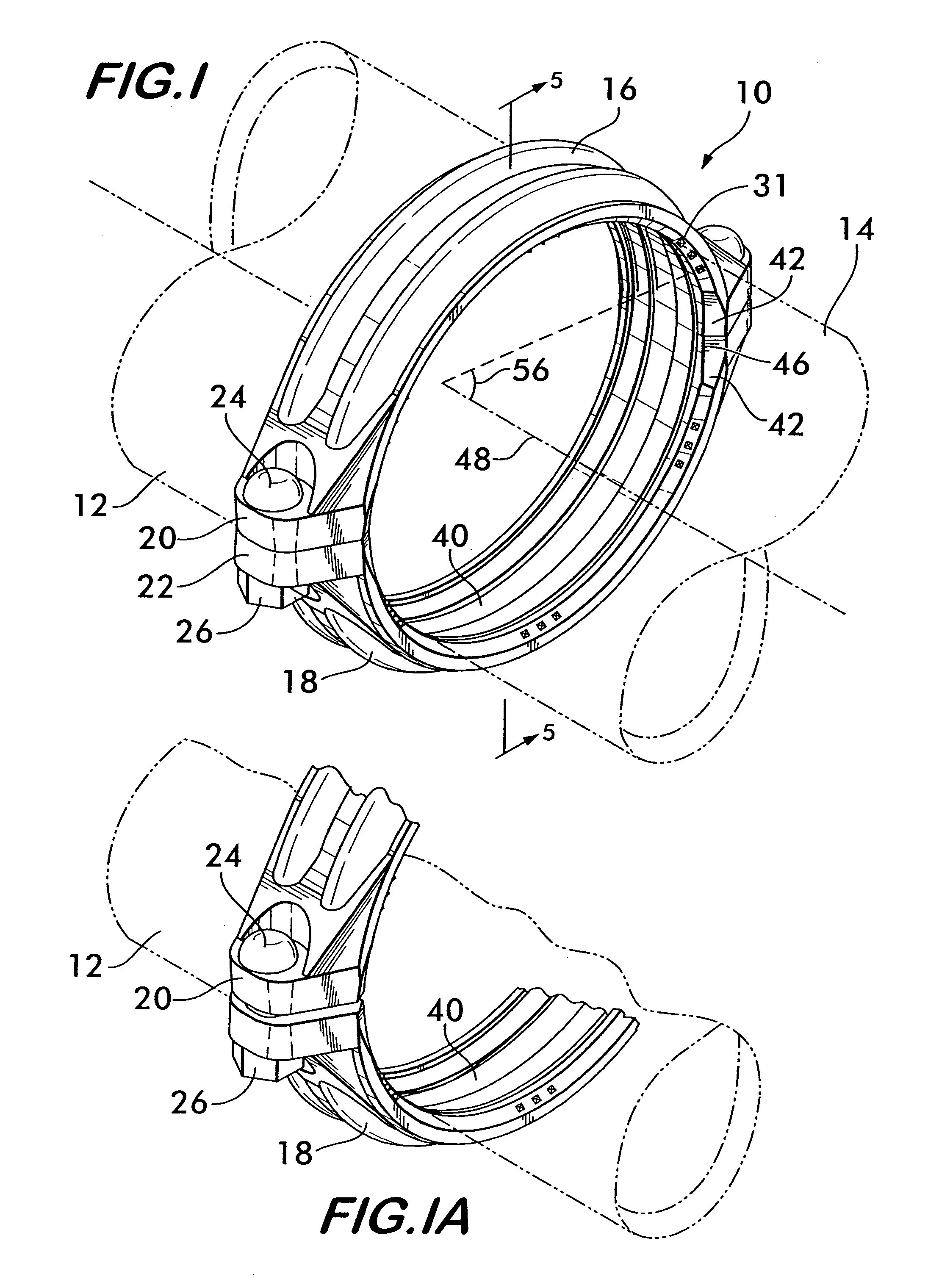

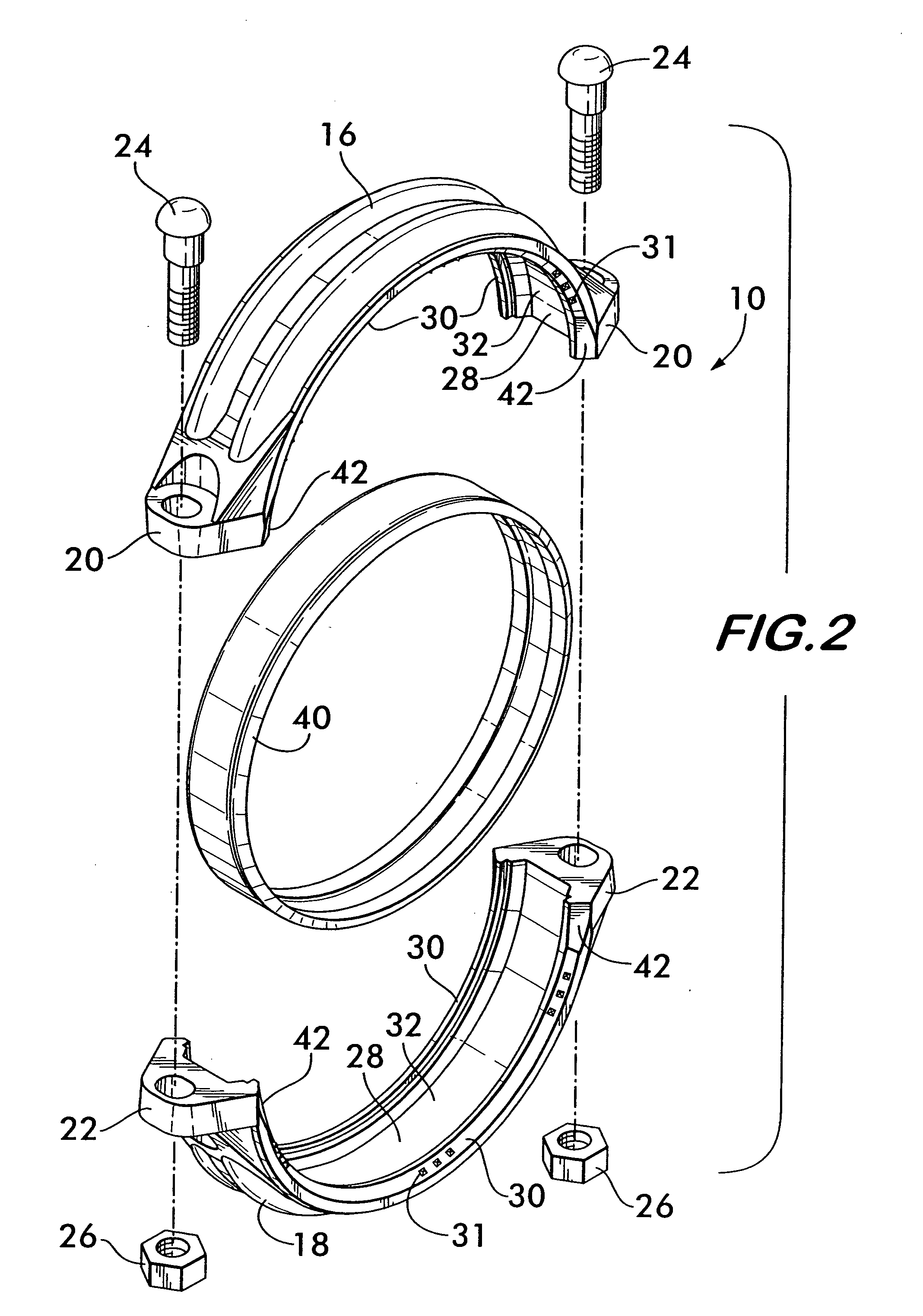

[0030]FIG. 1 shows a pipe coupling 10 for connecting two pipes 12 and 14 co-axially end to end. As shown in FIG. 2, coupling 10 is comprised of at least two segments 16 and 18. Each segment 16 and 18 has lugs 20 and 22 respectively, the lugs being positioned at or proximate to each end of the segments. The lugs 20 at each end of segment 16 align with the lugs 22 at each end of segment 18. Lugs 20 and 22 are adapted to receive fasteners, preferably in the form of bolts 24 and nuts 26 for joining the segments to one another end to end surrounding the pipes 12 and 14. In one embodiment, shown in FIG. 1, the lugs 20 engage the lugs 22 in what is known as “pad-to-pad engagement” with the lugs contacting one another when the segments 16 and 18 are properly engaged with the pipes 12 and 14 as explained below. The lugs may also be attached to each other in spaced apart relation when the segments 16 and 18 are properly engaged with the pipes 12 and 14, as illustrated in FIG. 1A.

[0031] Altho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com