Sole nail

a technology of sole nails and nails, applied in the direction of fastenings, uppers, bootlegs, etc., can solve the problem of not being able to rub easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order that those skilled in the art can further understand the present invention, a description will be described in the following in details. However, these descriptions and the appended drawings are only used to cause those skilled in the art to understand the objects, features, and characteristics of the present invention, but not to be used to confine the scope and spirit of the present invention defined in the appended claims.

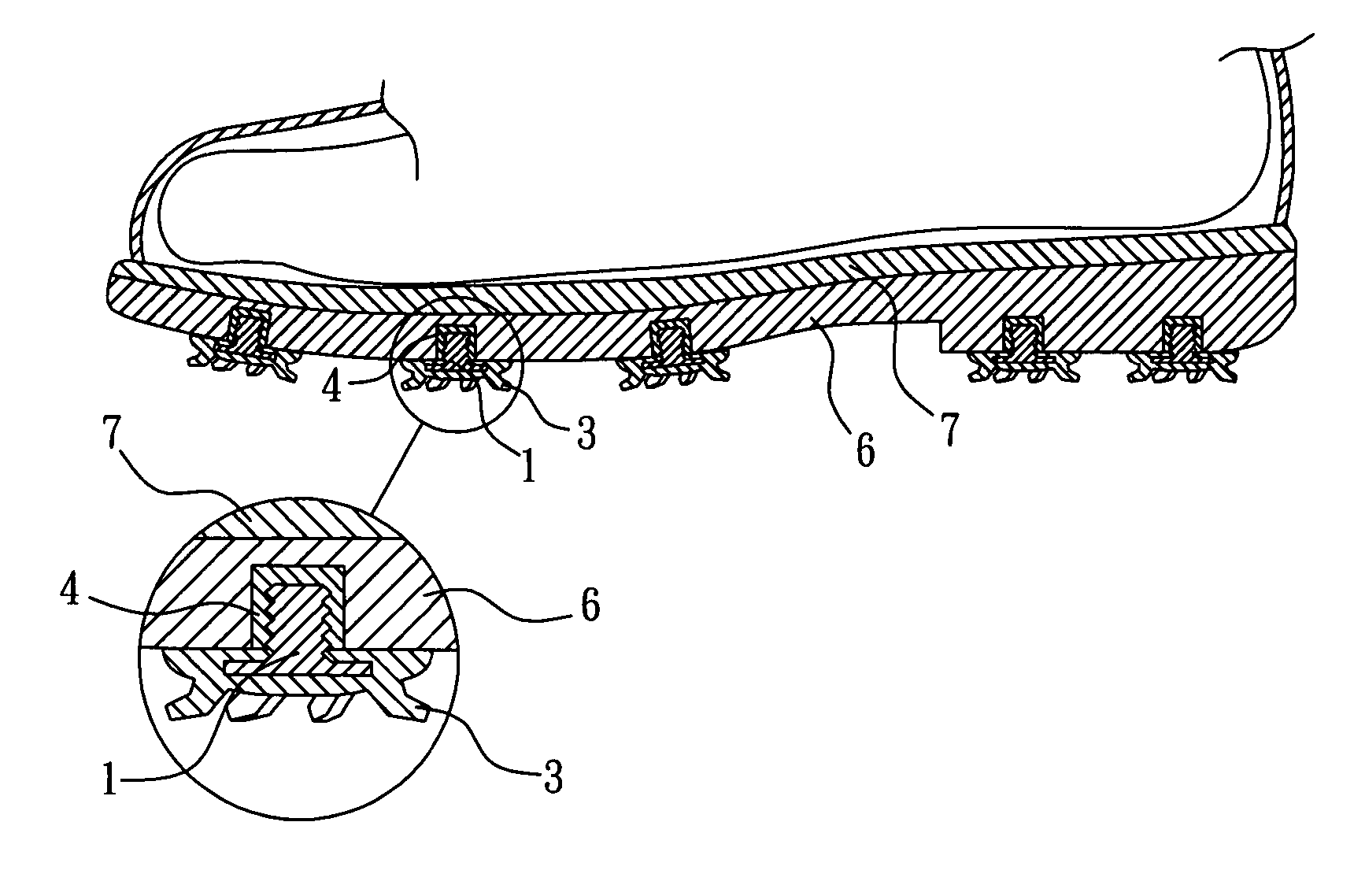

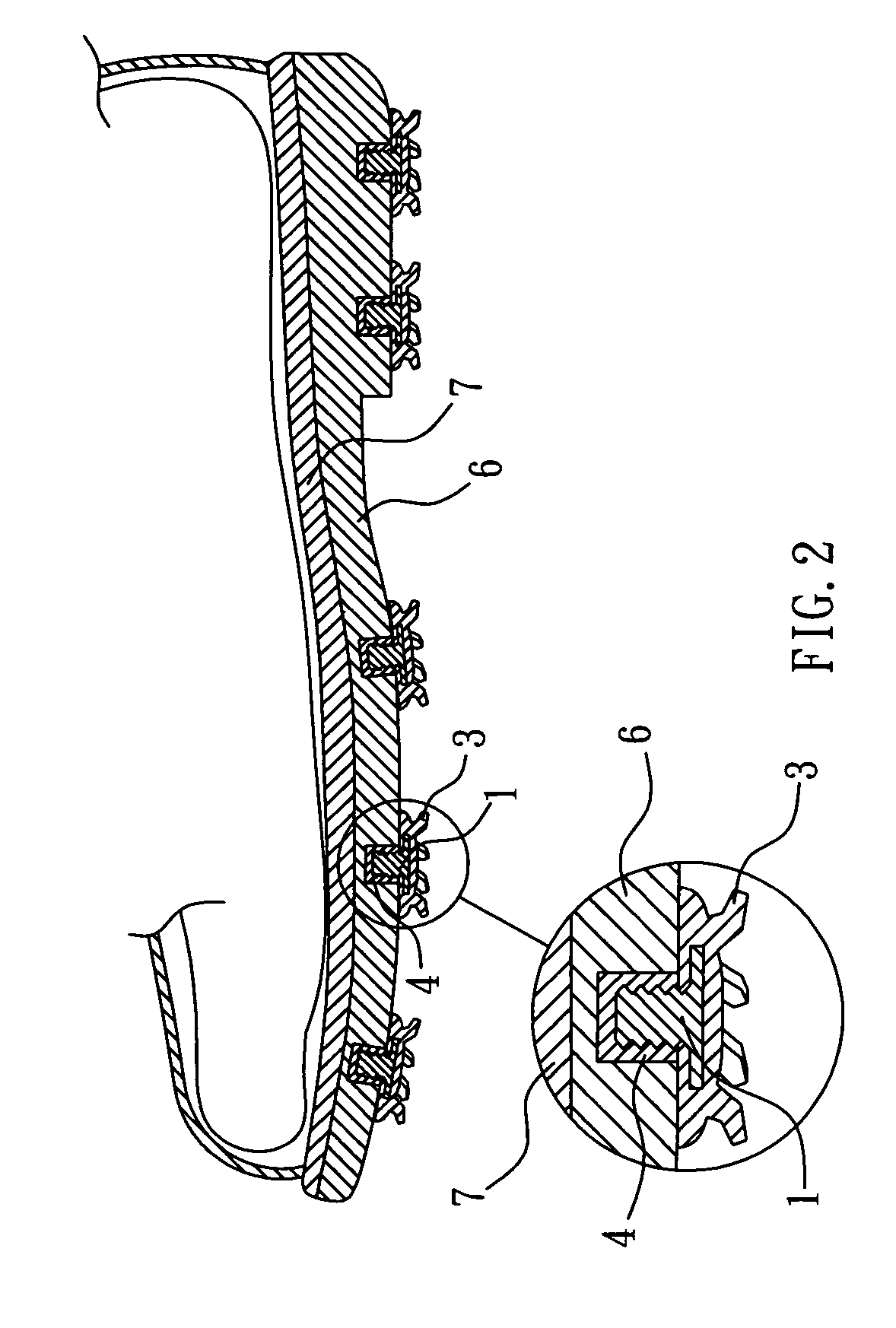

[0017] With reference to FIGS. 3, 4 and 5, the present invention comprises the following elements.

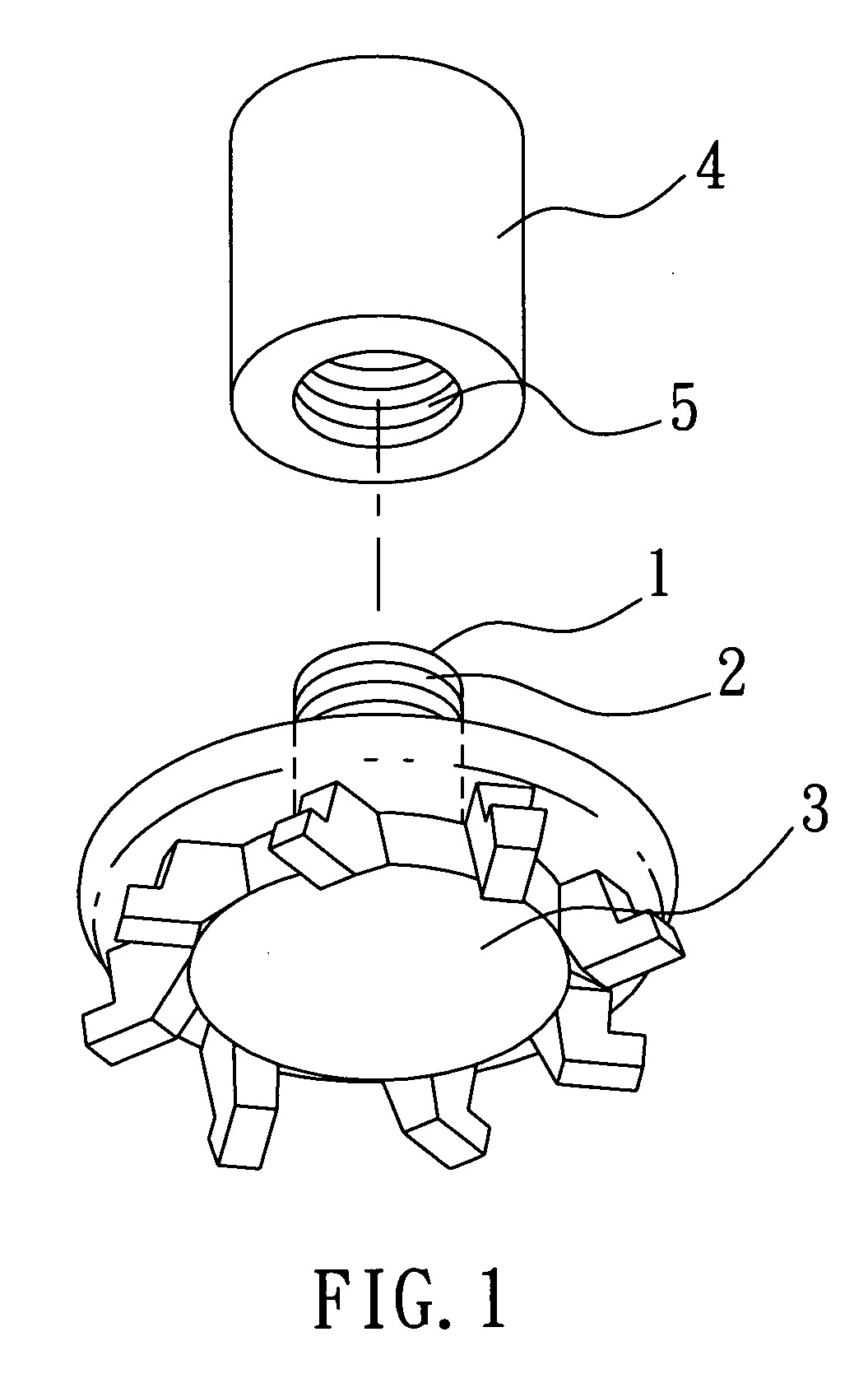

[0018] An assembly post 10 has a plurality of rubber claws 13. The assembly post 10 has a via hole 12 forming an upper and a lower opening (not shown) in the assembly post 10. A part of the assembly post 10 has thread 11.

[0019] An elastomer 23 encloses a periphery of the assembly post 10 having the thread 11.

[0020] A steel nail 22 passes through the via hole 12 of the assembly post 10. An upper end of the elastomer 23 resists against a bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com