I-joist web hole insert

a technology for inserting web holes and joists, which is applied to joists, girders, constructions, etc., can solve the problems of limited web area for cutting web holes, unable to meet the needs of construction workers, etc., and achieves the effect of convenient installation and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

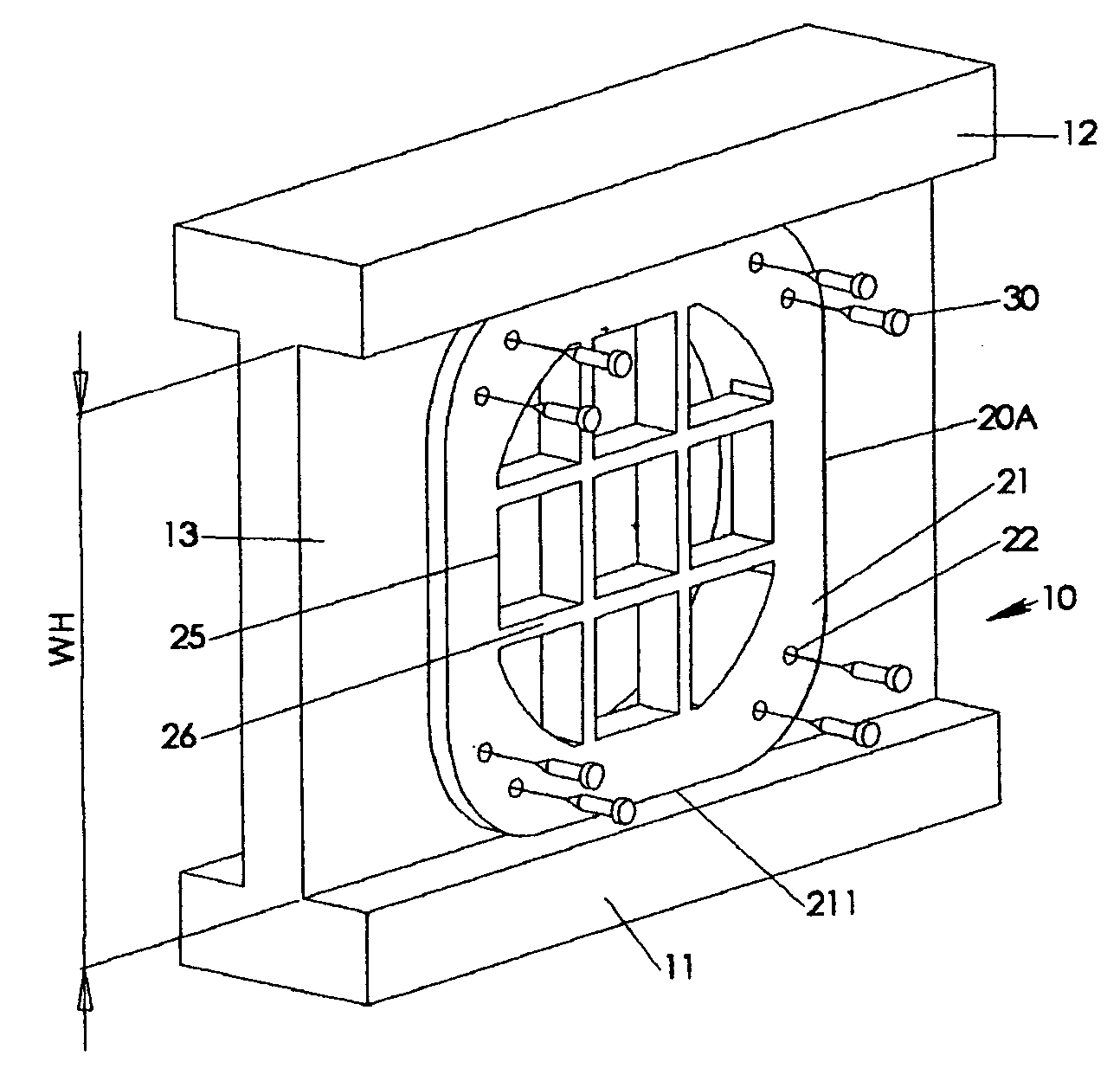

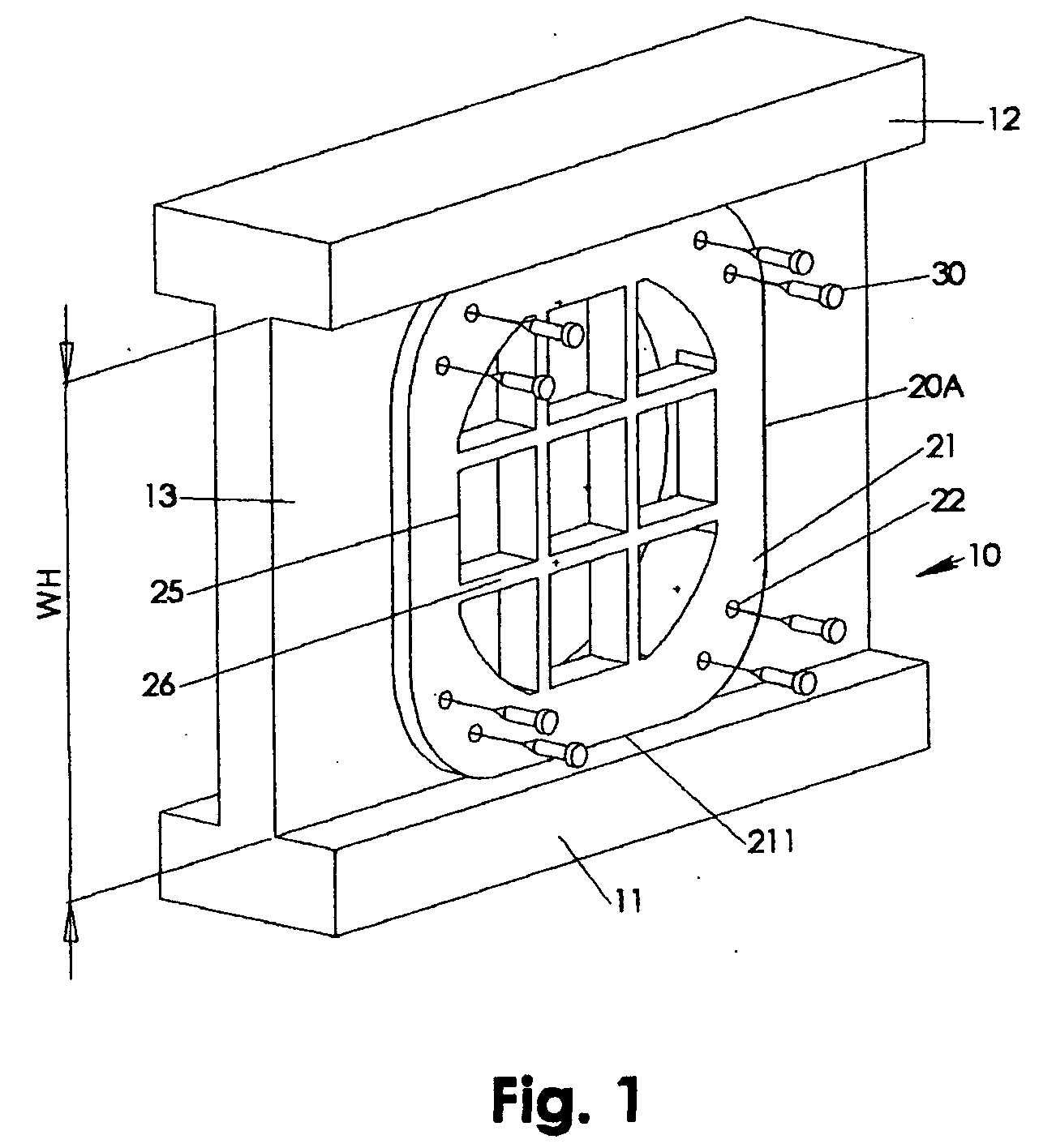

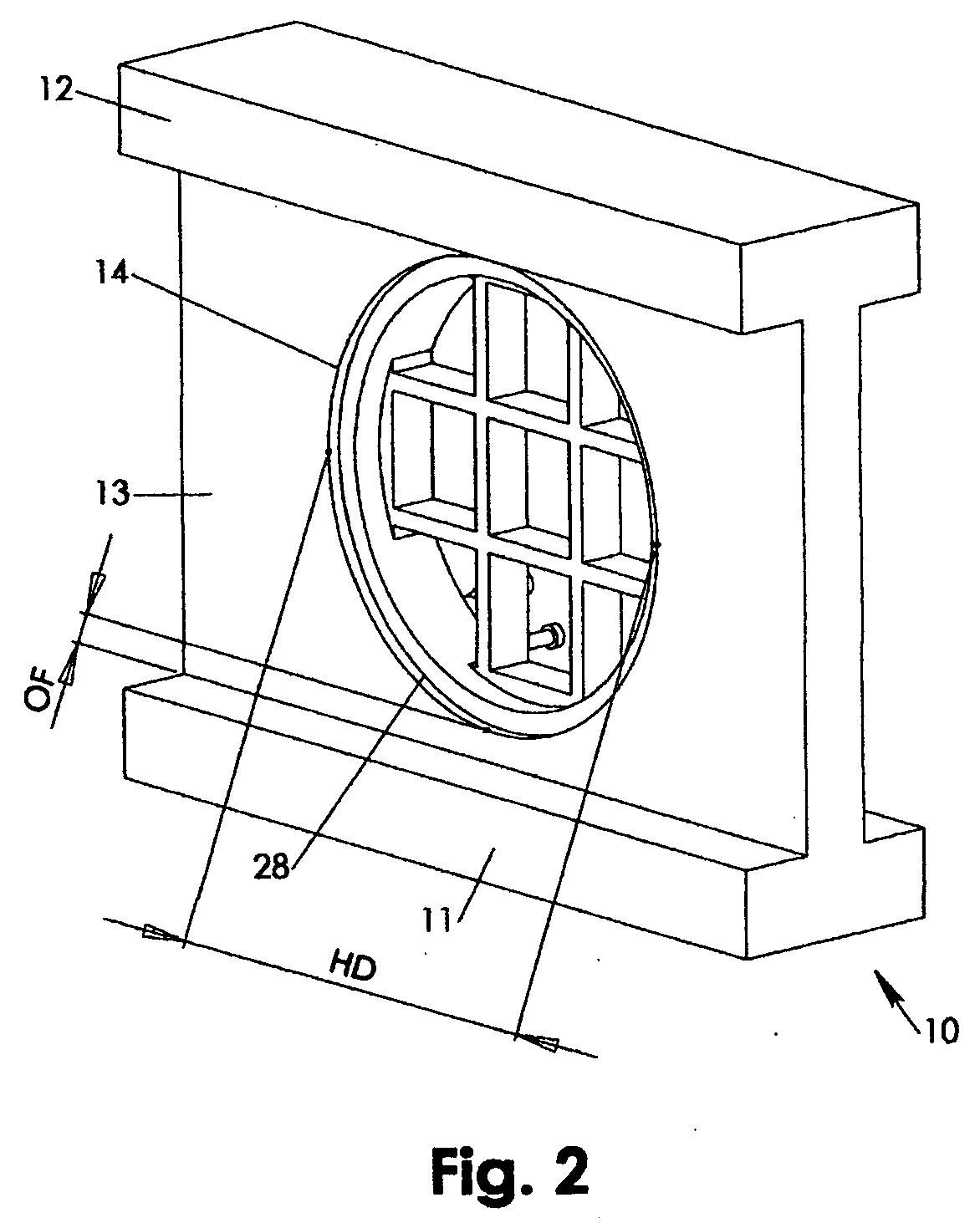

[0019] An I-joist 10, a portion of which is depicted in the Figures, may be combined with an insert 20A-20F in various configurations and eventual combination with other structures, such as attachment pins 30 as in FIG. 1, thread flange 40A, 40B as in FIGS. 5-7 and / or an I-joist support 50 as in FIG. 10. Attachment pins 30 may be nails, screws and the like well known in the field of architectural construction. The insert 20A-20F provides at least one cutout contour 25 for guiding at least one of a pipe, a tube, and a cable through the web hole 13 without direct contact between the web hole 13 and said at least one of a pipe, a tube and a cable, such that the web hole 13 edges are protected against inadvertent damaging.

[0020] According to FIG. 1, a first exemplary embodiment of an insert 20A may have a flange 21 for snuggly contacting the web portion 13 of I-joist 10. The flange 21 may have a circumferential contour that at least partially complies with at least one of the bottom ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com