Tire/wheel assembly

a technology for wheels and tires, applied in the field of tires/wheel assemblies, can solve the problems that the run-flat support body cannot be inserted into the inside of the pneumatic tire, and the mounting becomes impossible, and achieve the effect of enhancing the durability of the run-flat support body and reducing the rigidity of the bead cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

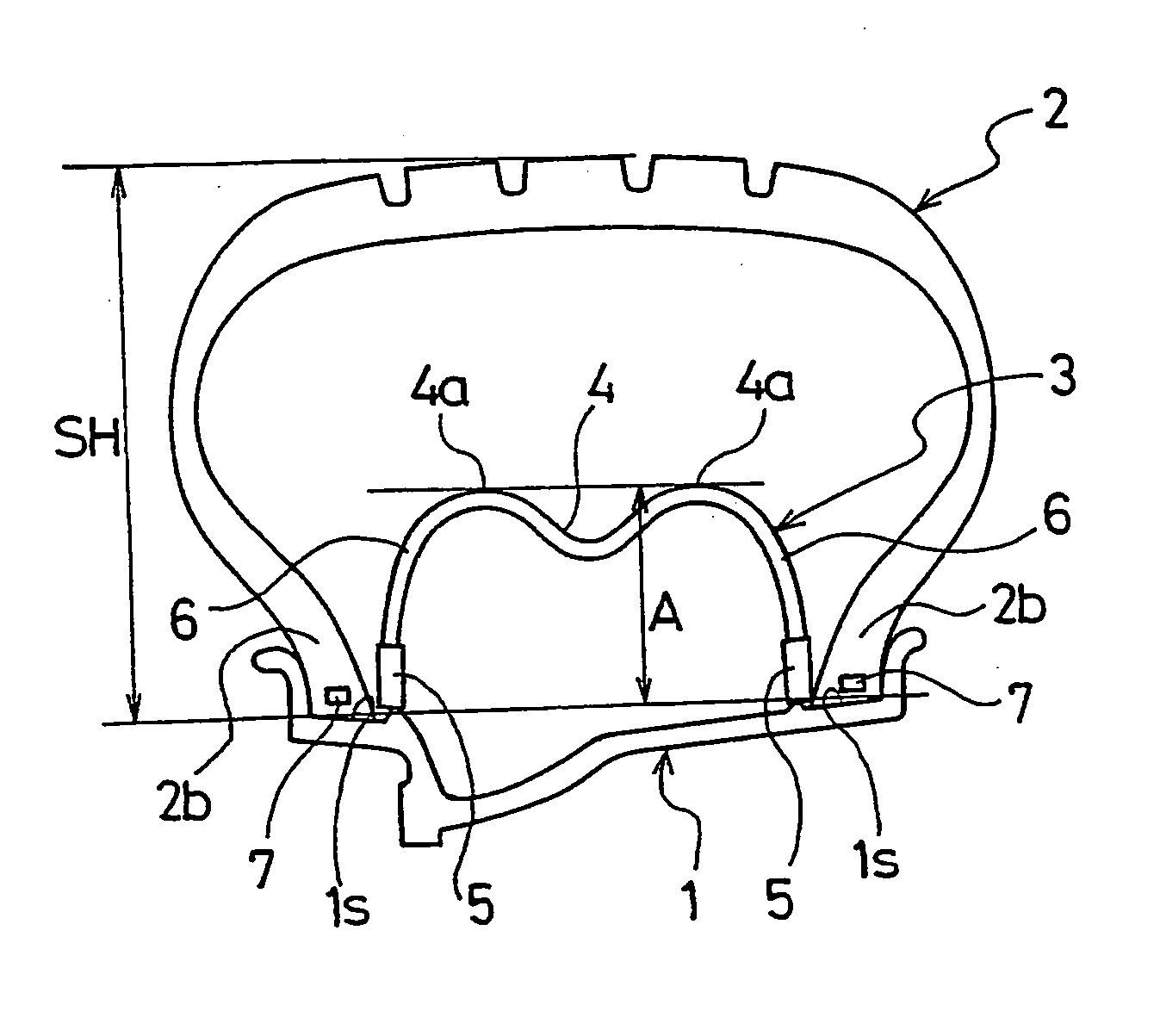

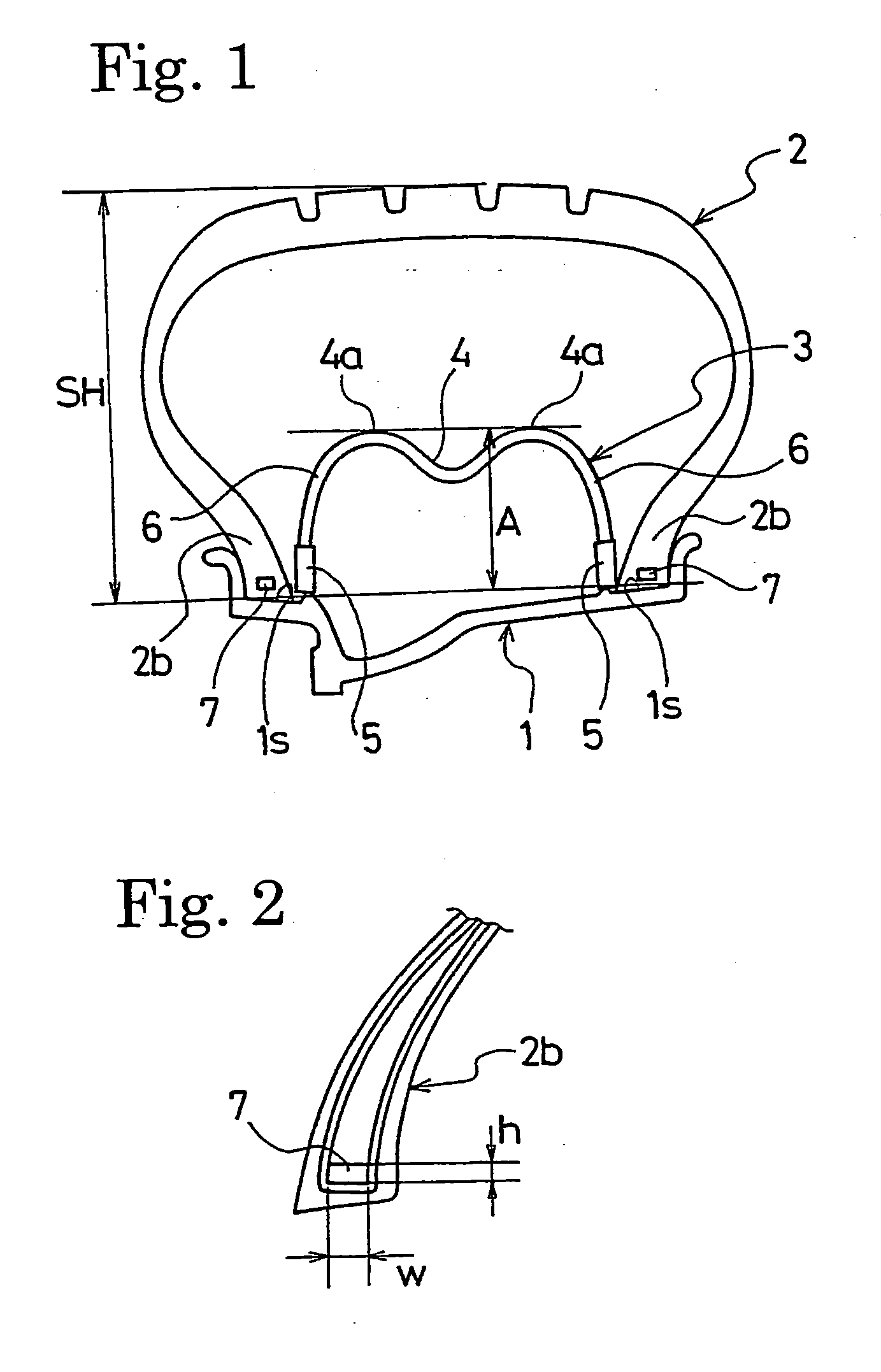

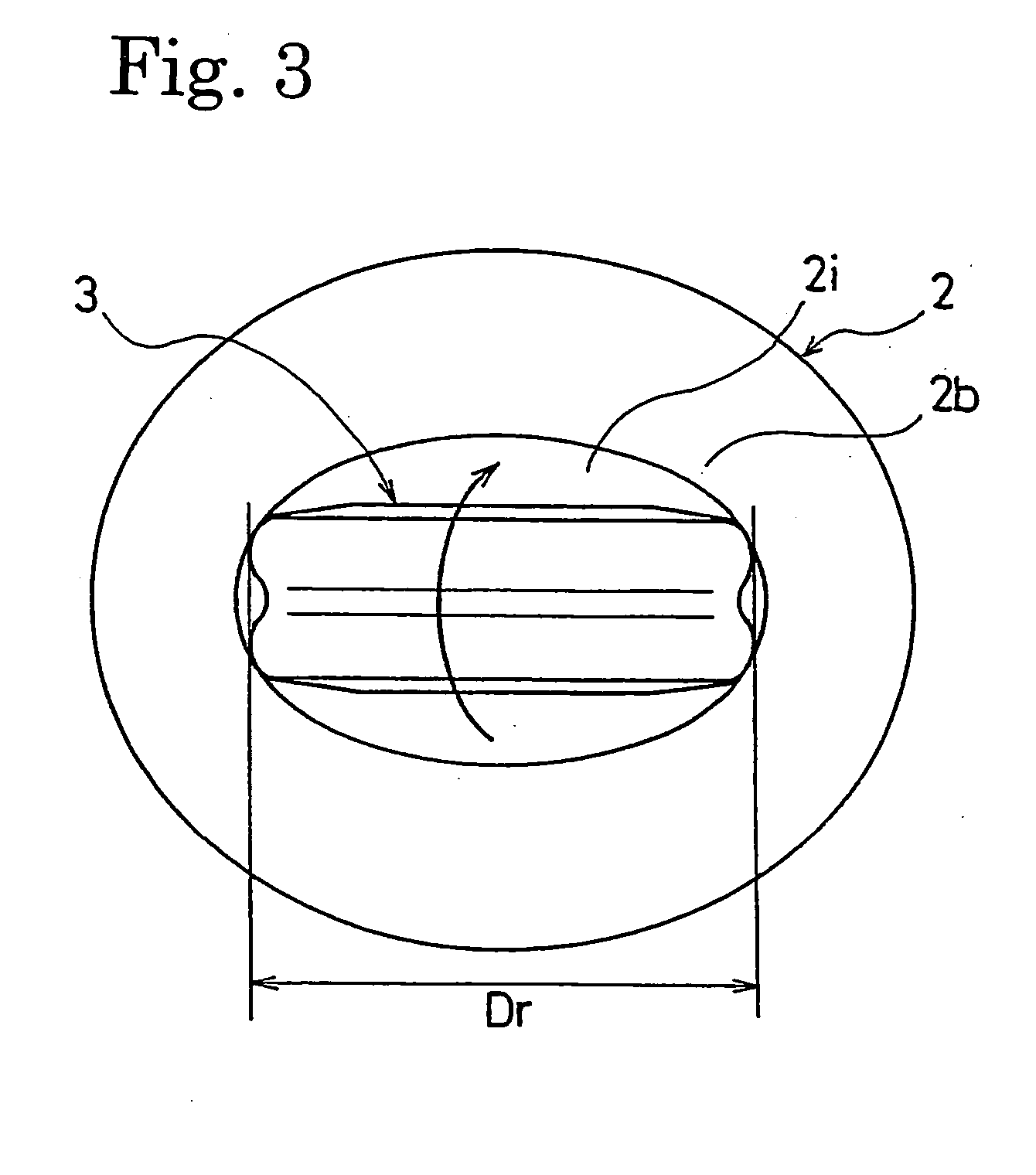

[0032] With 205 / 55R16 and 16×6 1 / 2JJ applied respectively as common tire size and rim size, seven types of tire / wheel assemblies (which are a conventional example, comparative examples 1 and 2, and embodiments 1 to 4) having various ratios of the height A of the run-flat support body in the cross section thereof relative to the height SH of the tire in the cross section thereof and various cross sectional areas of the bead core were manufactured.

[0033] Regarding these seven types of tire / wheel assemblies, ease of performing an inserting operation of the run-flat support body into the inside of the pneumatic tire (insertion operability), and the run-flat durability of the run-flat support body have been measured in accordance to the measurement method described below. Results are shown in Table 1.

[Run-Flat Durability]

[0034] Each tire / wheel assembly for testing was fitted to the left front side of a passenger car of 2500 cc displacement with a tire pressure set at 0. Meanwhile, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com