Male fixing member of hook-and loop fastener, and sheet product with the fixing member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

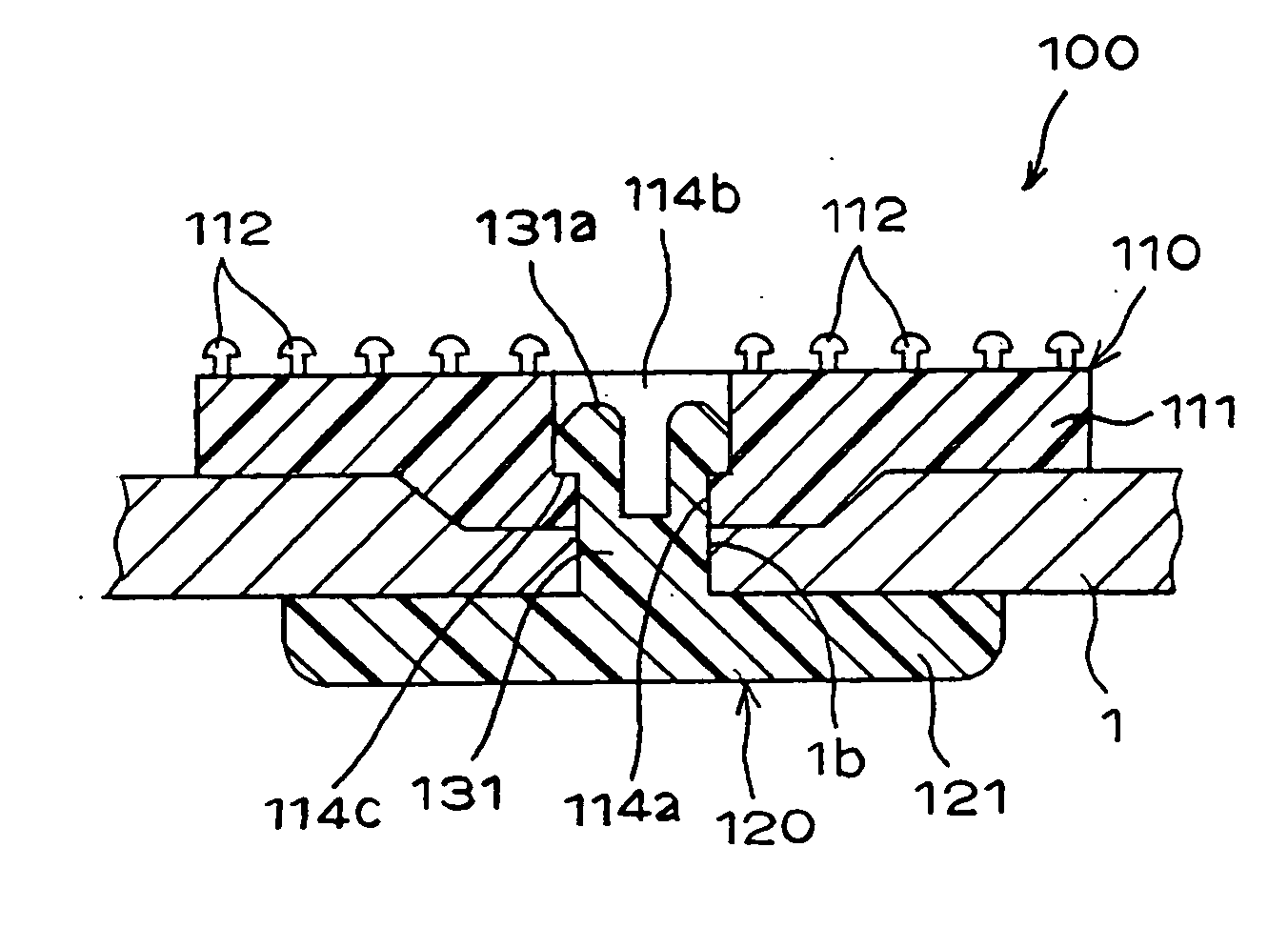

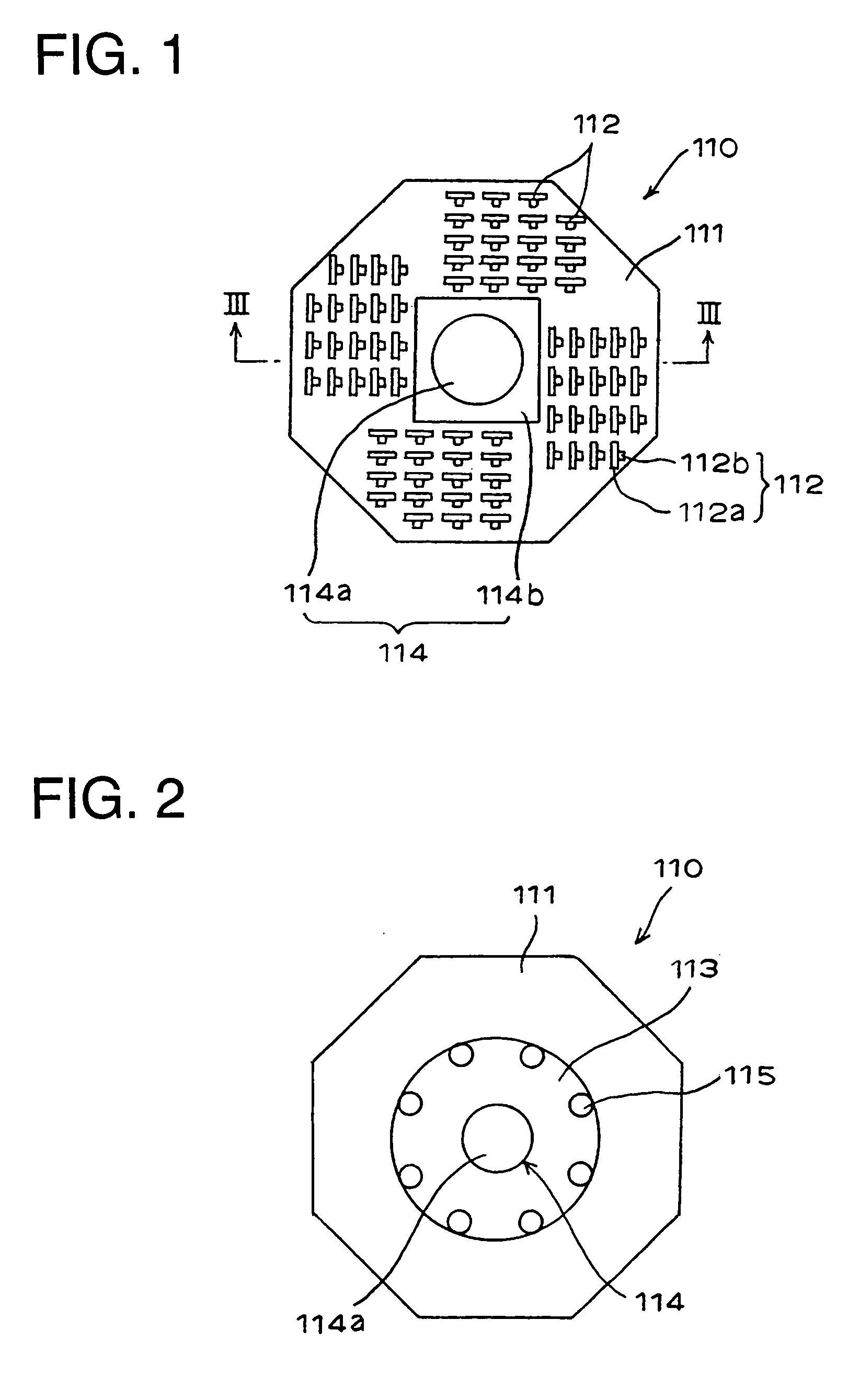

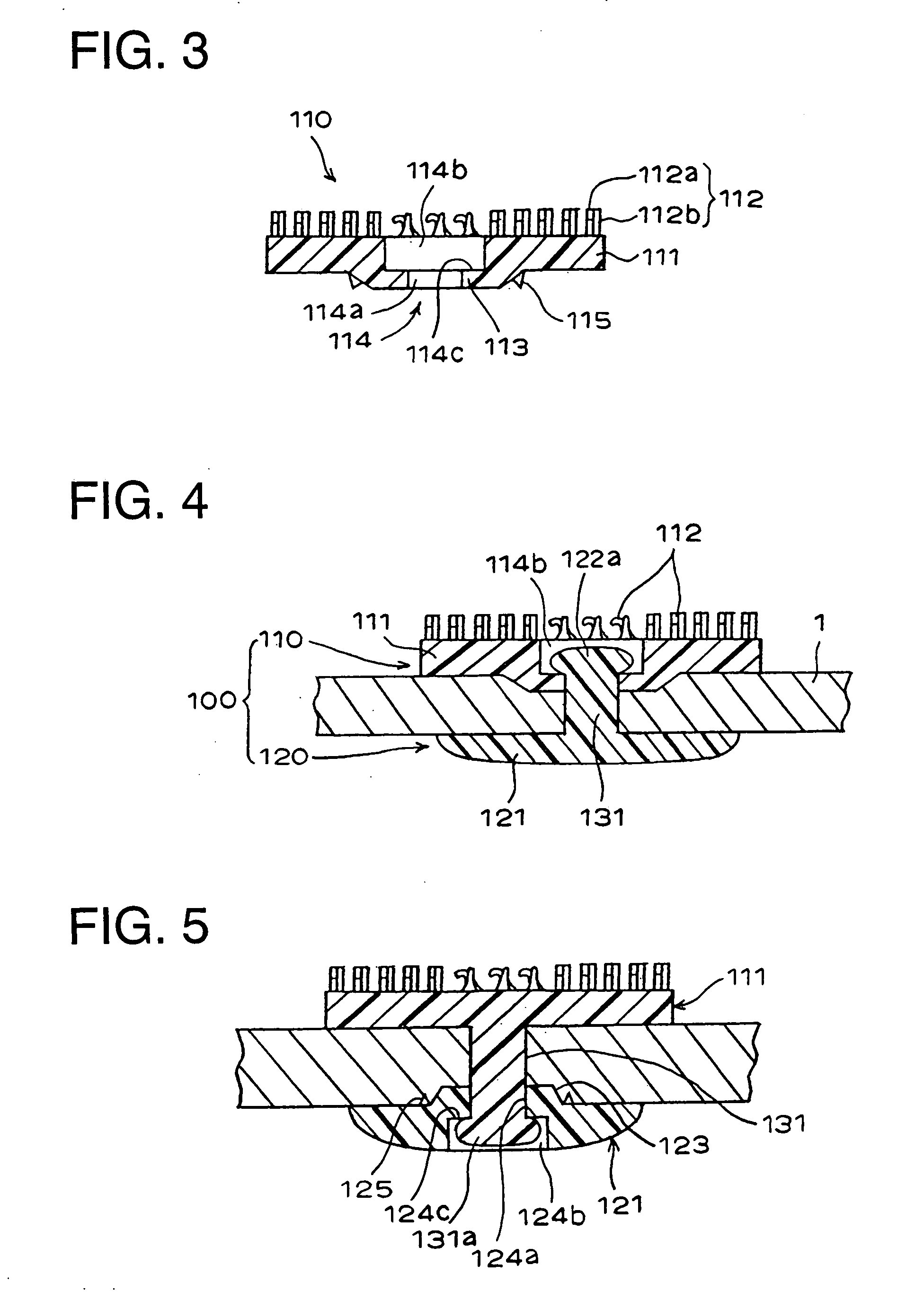

[0036] FIGS. 1 to 4 show the male fixing portion of the male fixing member according to the present invention and FIG. 1 is a front view thereof, FIG. 2 is a rear view thereof and FIG. 3 is a sectional view taken along the line III-III in FIG. 1 and FIG. 4 is a sectional view showing a condition in which the male fixing member is attached to a fabric of clothes.

[0037] As shown in FIG. 4, a male fixing member 100 of the present invention comprises a male fixing portion 110 and a fastening portion 120. The male fixing portion 110 is constituted of a male member which comprises a first base material 111 composed of a button-like flat piece and a number of male engaging elements 112 projecting from a surface of the base material, and the male member joins with or separates from a loop piece as a mating engaging member of the surface fastener and is generally called male surface fastener. The male fixing portion of this embodiment is obtained directly by injection molding of thermoplasti...

third embodiment

[0046]FIG. 7 shows the present invention. According to this embodiment, the entire male fixing member 100 is formed integrally of the same synthetic resin material. That is, as indicated in the same Figure, the first base material 111, the engaging elements 112, the column-like joint portion 131 and the second base material 121 are all molded integrally. When attaching the male fixing member 100 having such a structure to the clothes 1, a slit-like button hole 1a is formed in the attachment portion of the clothes 1 as shown in the same Figure, for example, and the second base material 121 of the fastening portion 120 is inserted from an inside face side of the button hole 1a, and exposed outside and attached.

[0047]FIG. 8 shows an example of modification that most portion of the male fixing member 100 of the present invention except the above engaging elements 112 is molded integrally with metallic material at the same time. A difference of this modification from the above-described ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Metallic bond | aaaaa | aaaaa |

| Durability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com