CIPP pipeline structural repairing method

A repair method and structural technology, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of effective repair of difficult-to-pressure pipes, long resin curing time, high cleaning requirements, etc., to achieve convenient and fast construction. , The effect of fast construction and low operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] Embodiments of the present invention provide a CIPP pipeline structural repair method, comprising the following steps:

[0032] S1 blocks the upstream and downstream of the pipeline to be repaired, cleans the inside of the pipeline to be repaired, and repairs the flatness of the inner wall of the pipeline to be repaired.

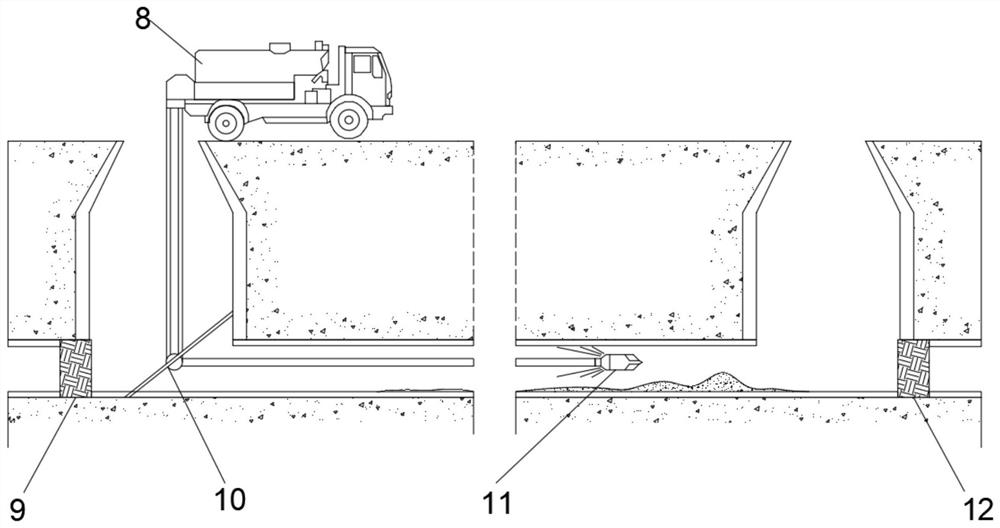

[0033] Specifically, please refer to image 3 , at first the upstream and downstream of the pipeline 1 to be repaired respectively select an inspection well, respectively use the upstream plug 9 and the downstream plug 12 to block the upstream and downstream of the pipeline 1 to be repaired in the two inspection wells, and the upstream plug 9 and the downstream plug 12 are inflatable airbags, and the accumulated water in the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com