Sealing method for leakage check of transformer finned radiator, and inner hook sealer special for leakage check of transformer finned radiator

A technology for radiators and transformers, which is used in the use of liquid/vacuum for liquid tightness measurement, pipes/pipe joints/fittings, mechanical equipment, etc. and other problems, to achieve the effect of high tensile and shear strength, high efficiency and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

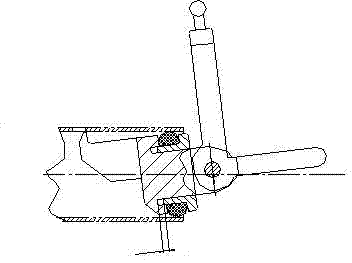

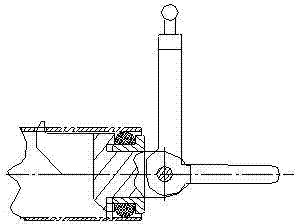

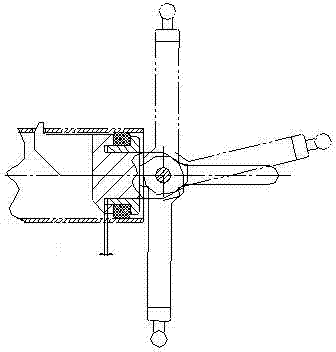

[0019] Hook sealer for leak test of transformer chip radiator, including handle piece 1, rubber ring 2, rubberized steel sleeve 3, cam handle 4, cam shaft 5, the front end of the handle piece is a handle, and the rear end is a hook shape Structure, the middle horizontal direction is a cylindrical stepped structure, the end close to the handle has a smaller diameter, and the end close to the hook-shaped structure has a larger diameter, the inner diameter of the rubber ring and the rubberized steel sleeve is smaller than the maximum outer diameter of the stepped structure, which are sequentially set on the On the step in the middle of the handle piece, the cam rotating shaft is arranged on the handle piece, close to the rubberized steel sleeve, and the cam handle is arranged on the cam rotating shaft. Laminated steel sleeves are slidable. Because...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com