Slide fastener

a slide fastener and slide technology, applied in the field of slide fasteners, can solve the problems of difficult to provide a low cost electromagnetic wave shield slide fastener or an electromagnetic wave shield slide fastener having good flexibility and high quality, and achieve the effects of low cost, easy installation and high quality produ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

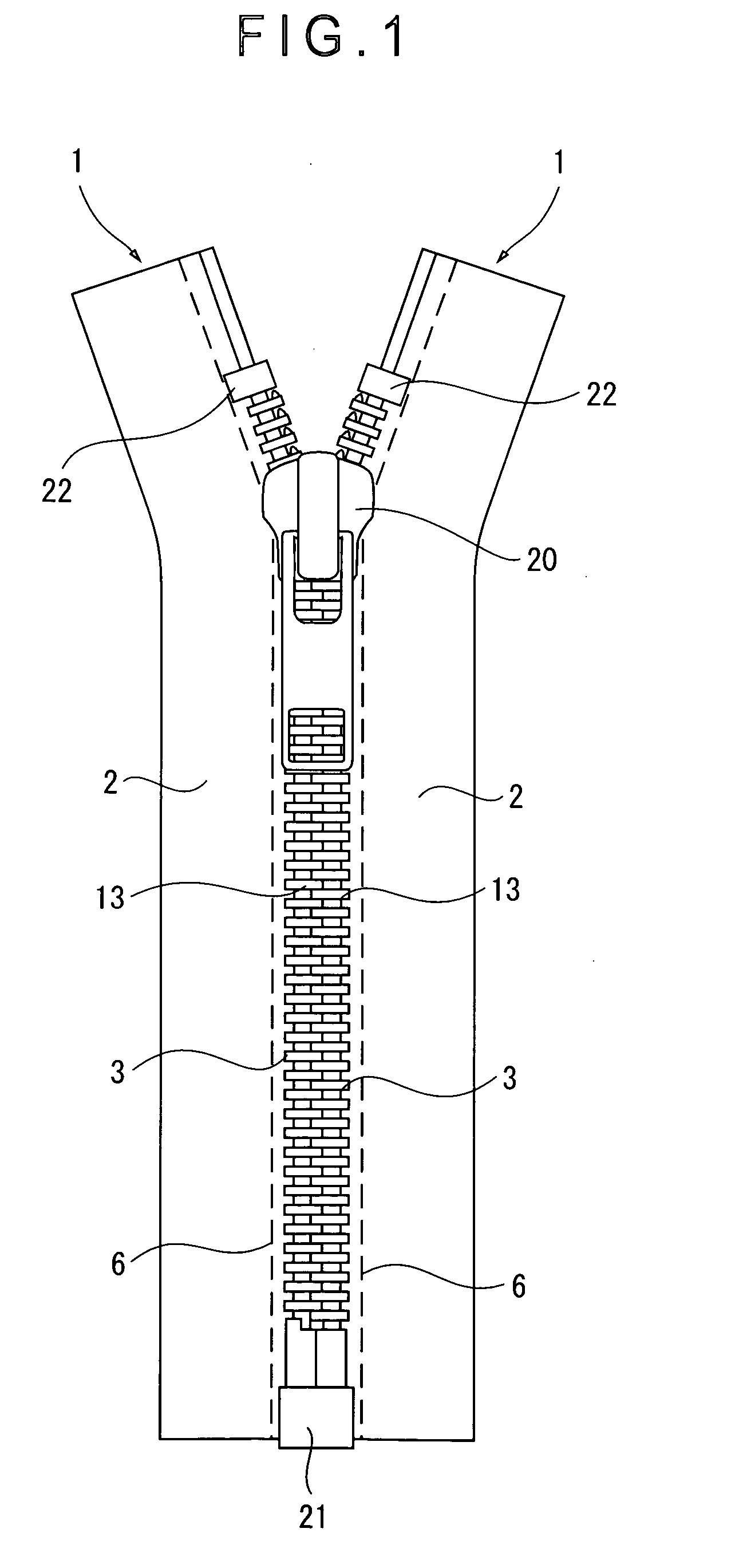

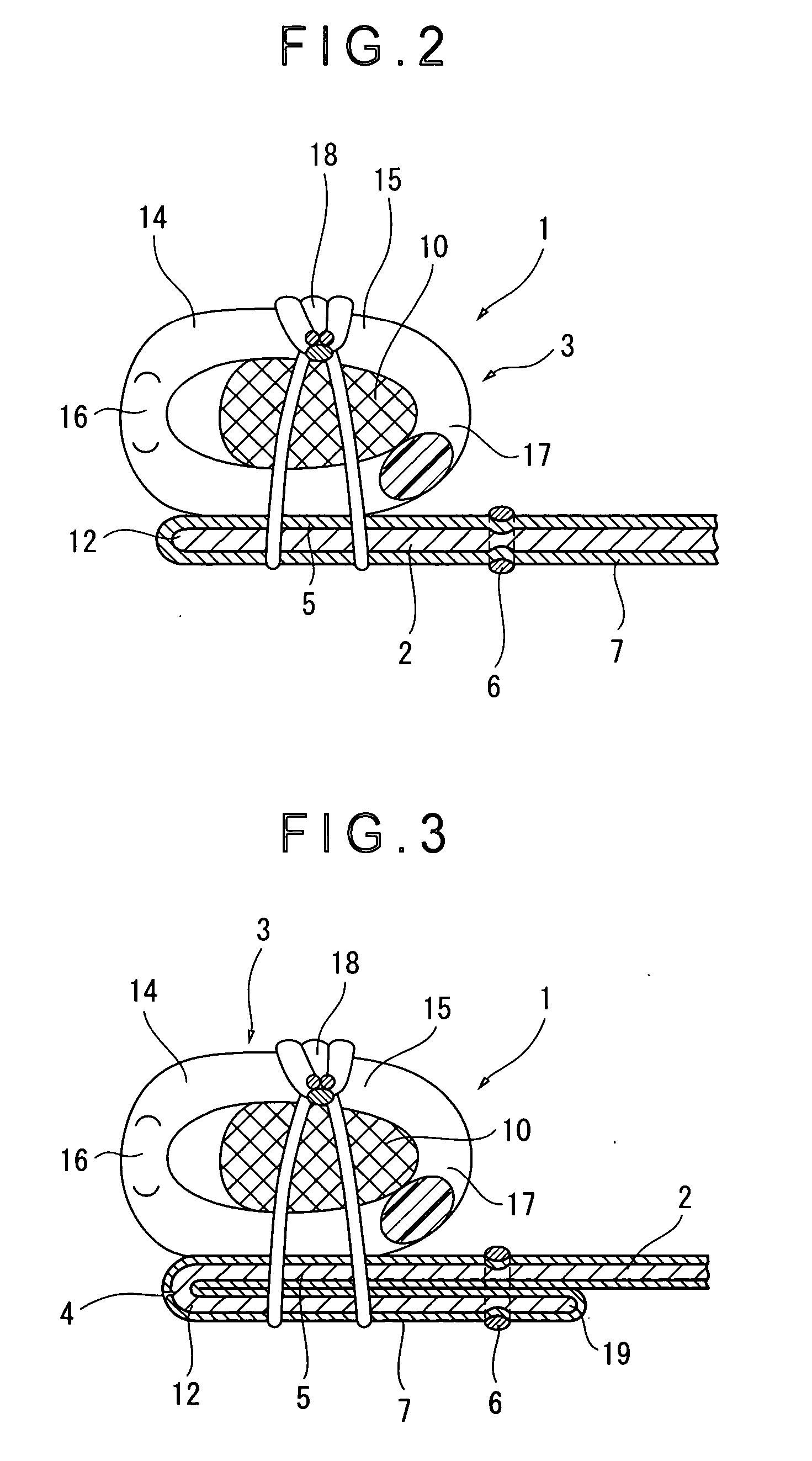

[0037] The embodiments of slide fasteners according to the present invention are hereunder specifically explained referring to the drawings.

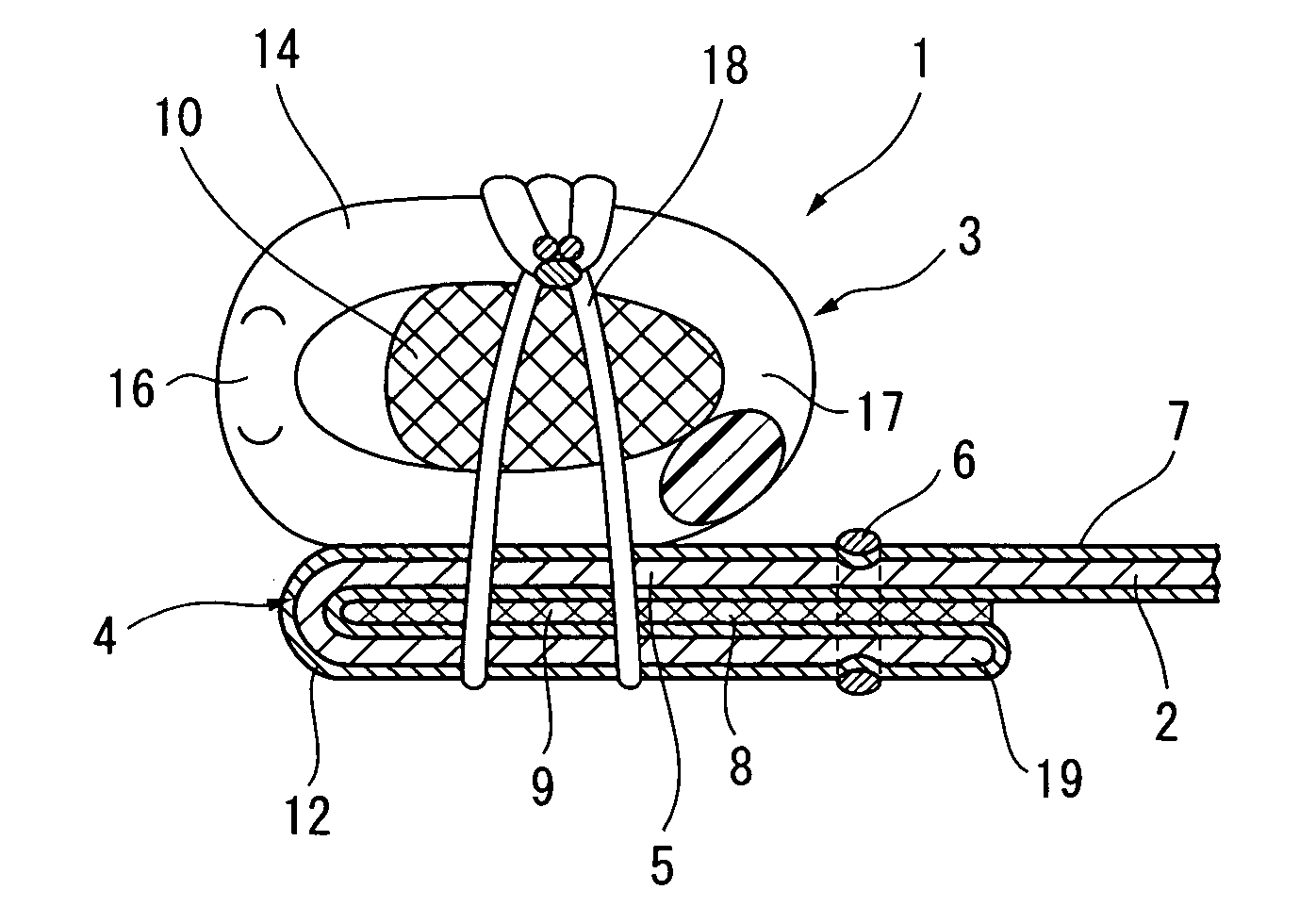

[0038]FIG. 1 shows a slide fastener according to the present invention.

[0039] As the first feature of the slide fastener, a special performance mechanism is provided to the basic functions of the slide faster. More specifically, in order to provide the faster tape 2 of a fastener stringer 1 with electromagnetic wave shield performance, metal plating is applied onto the surface of the fastener tape 2 to form a shield coating 7. In addition, in order to provide the fastener tape 2 further with fire-resistant performance, the surface of the shield coating 7 formed on the surface of the fastener tape 2 is coated with a fire-resistant additive and thus the fire-resistant coating 7 is formed.

[0040] The second feature of the slide fastener is as follows. Before attaching fastener elements 3 to the fastener tape 2 of a fastener stringer 1, the fasten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com