Candle wick centering device and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

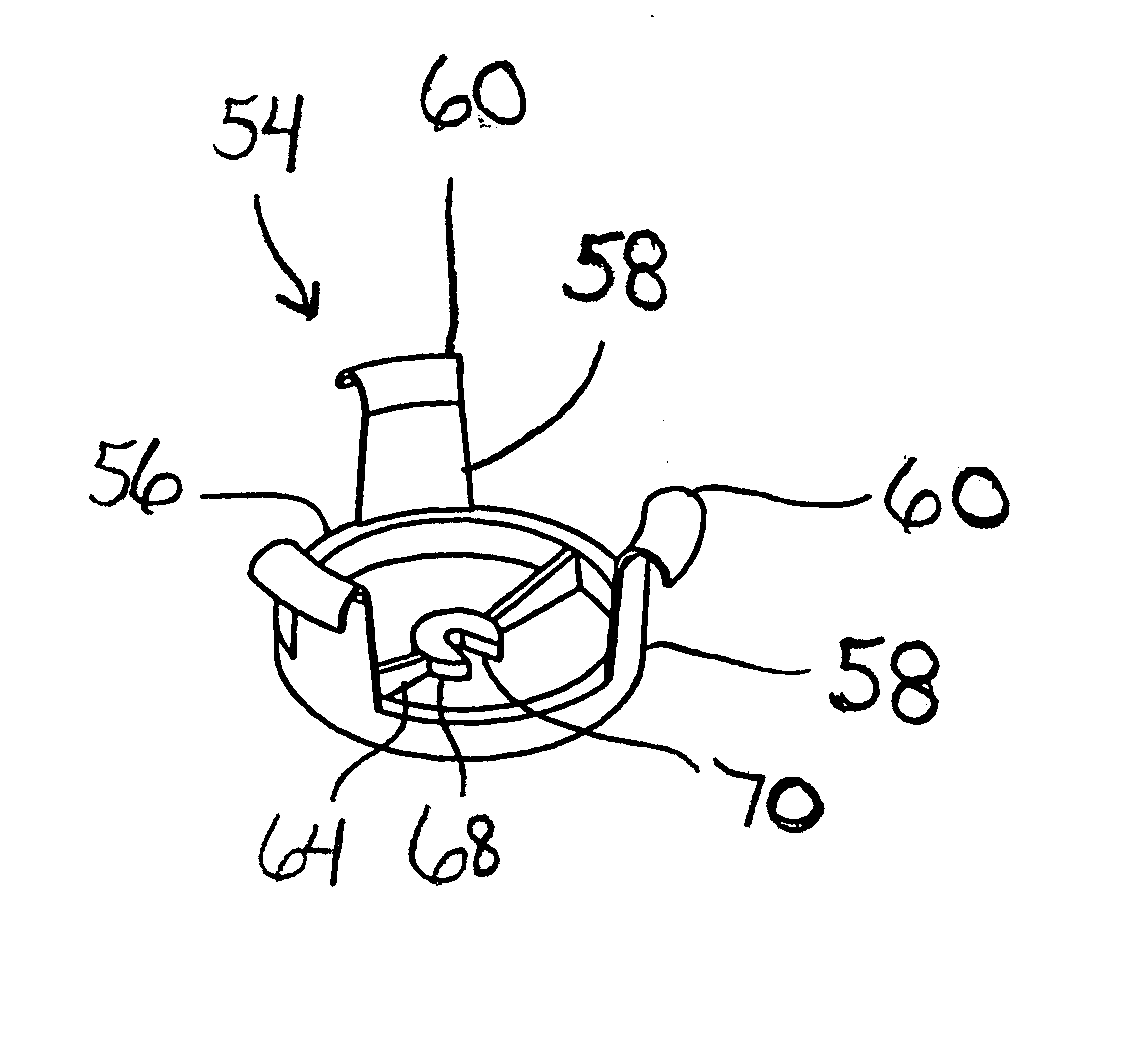

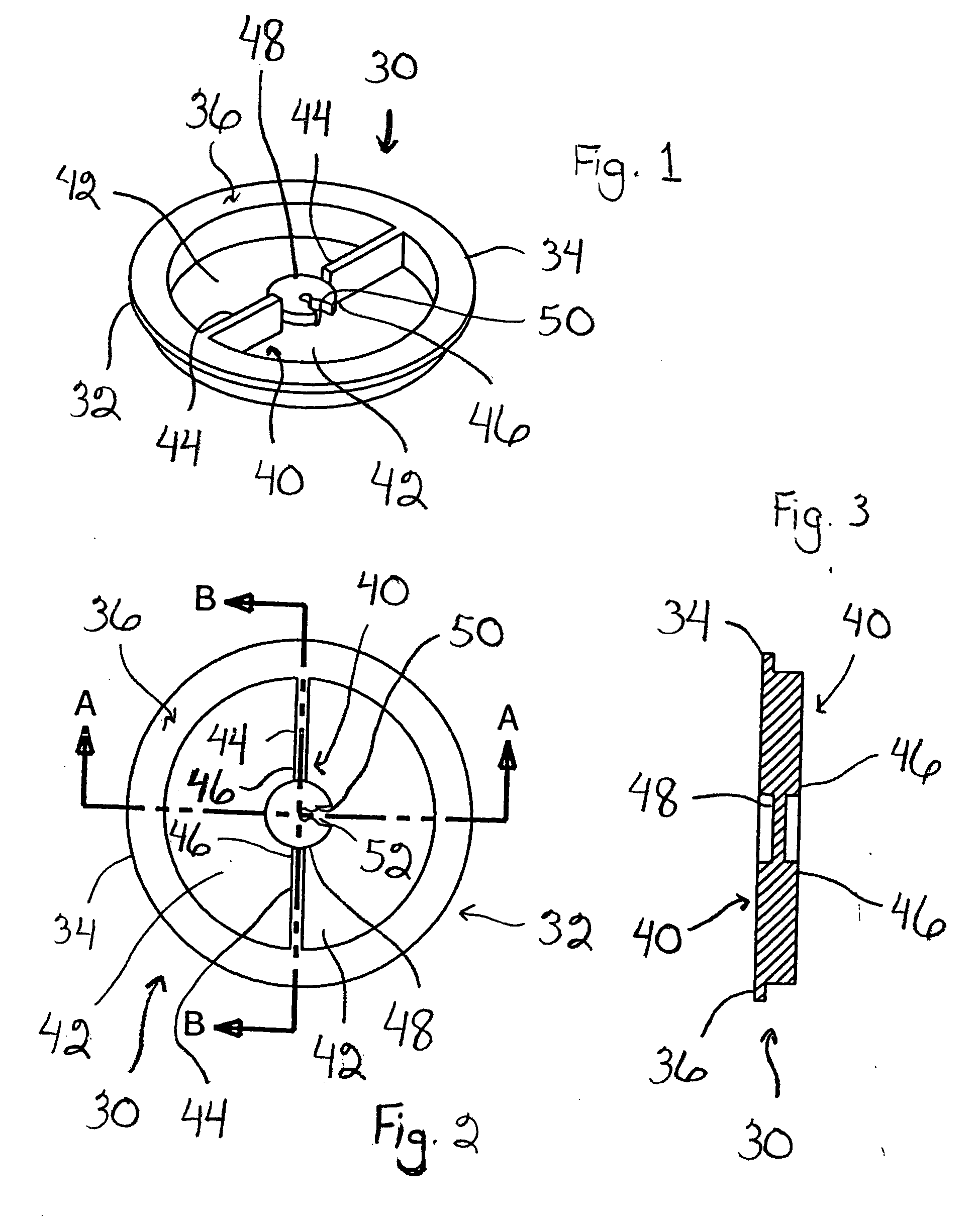

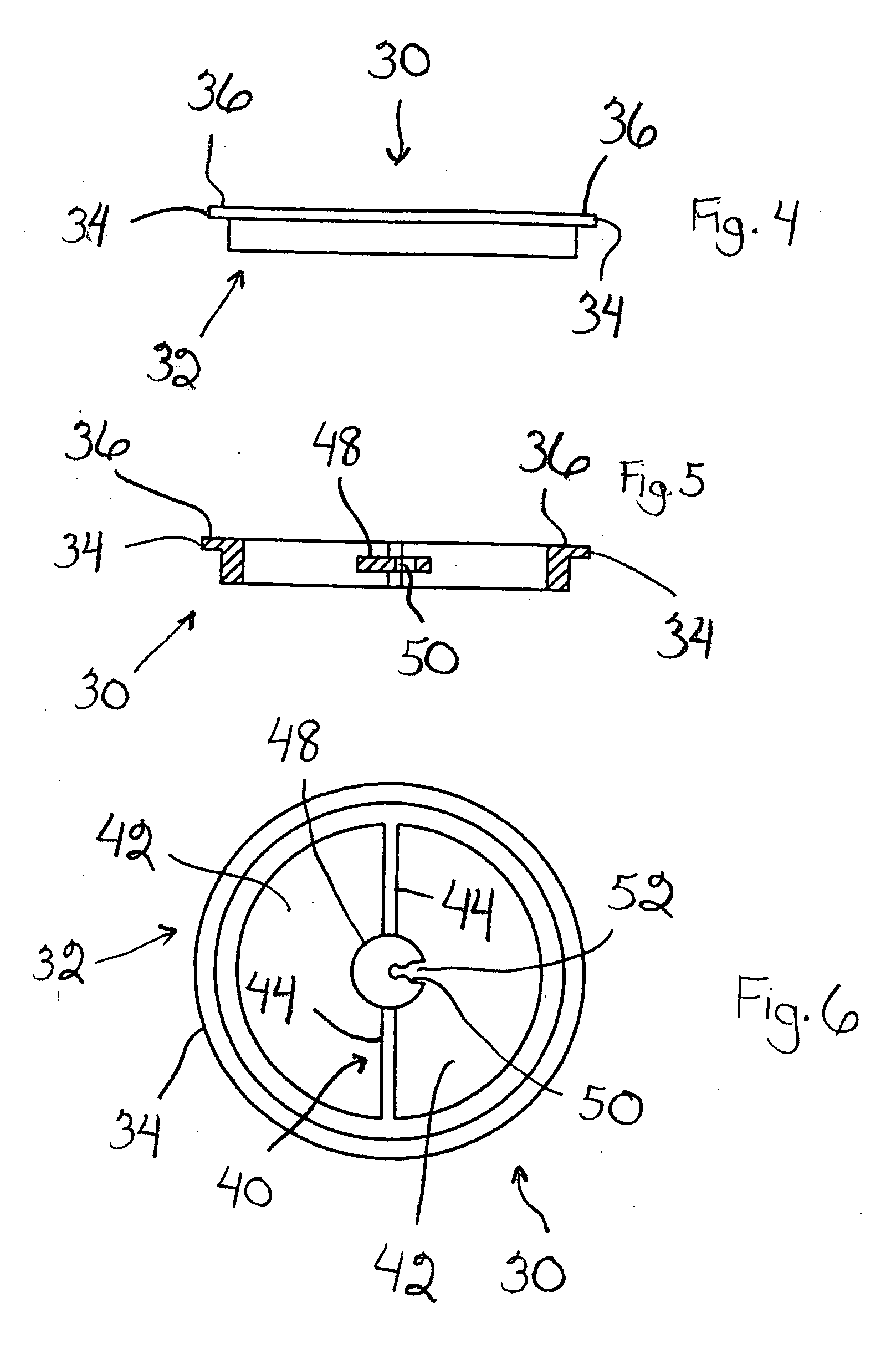

[0043] Illustrated in FIGS. 1-13 and 16-22 are several embodiments for a candlewick-centering device for holding and maintaining the vertically centered position of candle wick within a candle container throughout the wax pouring and wax hardening and solidifying processes. Throughout this description, similar parts among the embodiments are given the same part number. Candle containers come in numerous sizes, shapes, dimensions, and designs; a representative type of candle container, also referred to as a jar candle, is shown in FIGS. 14 and 15. The candle container 10 includes a bottom surface 12 and a continuous sidewall 14 that extends upwardly from bottom surface 12. The sidewall 14 defines a cavity 16 wherein the candle wax 18 is poured and solidified for forming the candle. Further, the sidewall 14 includes an upper rim 20 that defines an open top 22, and the open top 22 can be closed off by a lid or cap 24 when the candle is not in use. Projecting upwardly from the bottom su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap