Guide adapter with claw contour

a technology of adapter and contour, which is applied in the direction of power-driven reciprocating saws, metal sawing accessories, manufacturing tools, etc., can solve the problems of torque generation and unsuitability of prior art guide adapters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

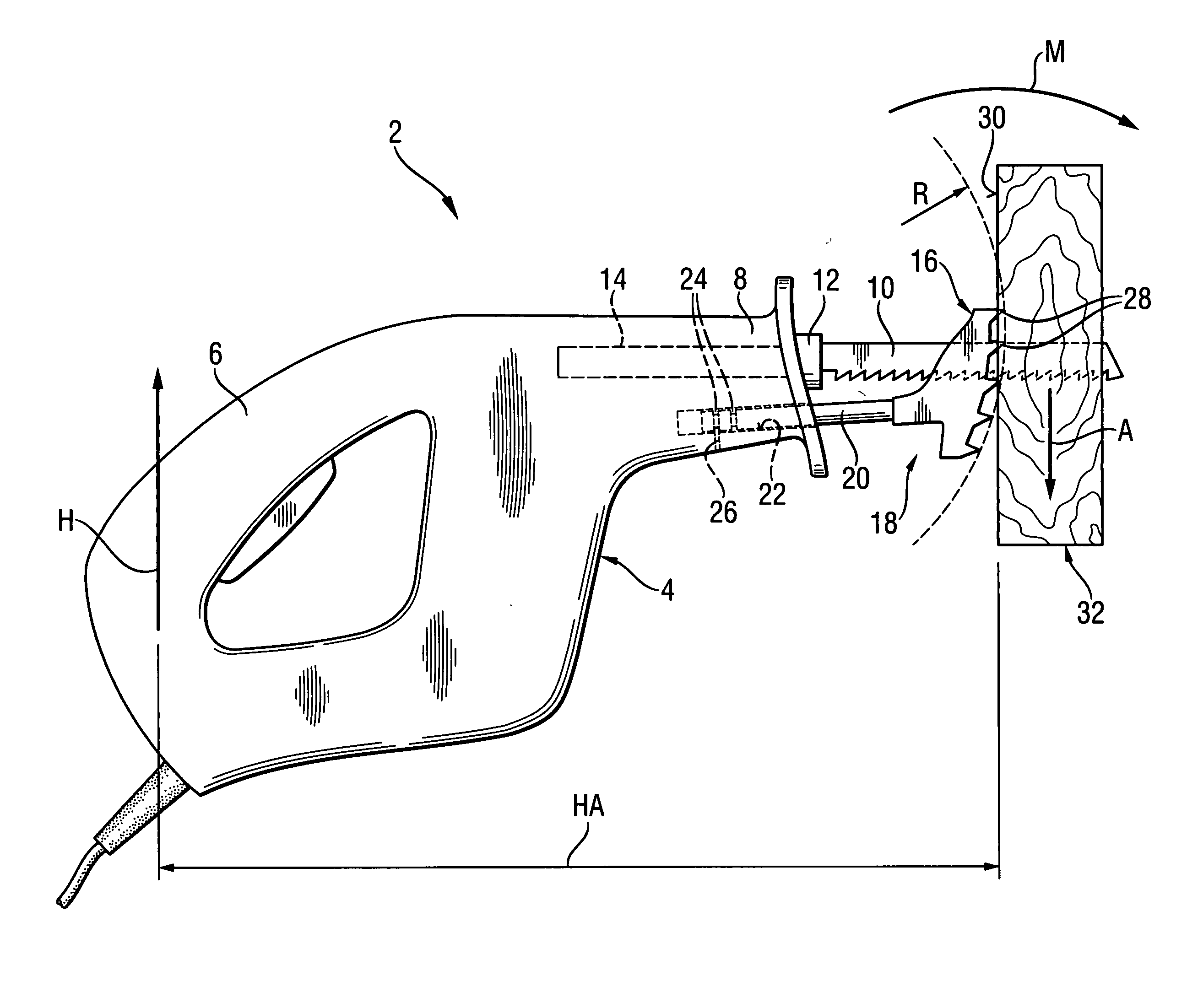

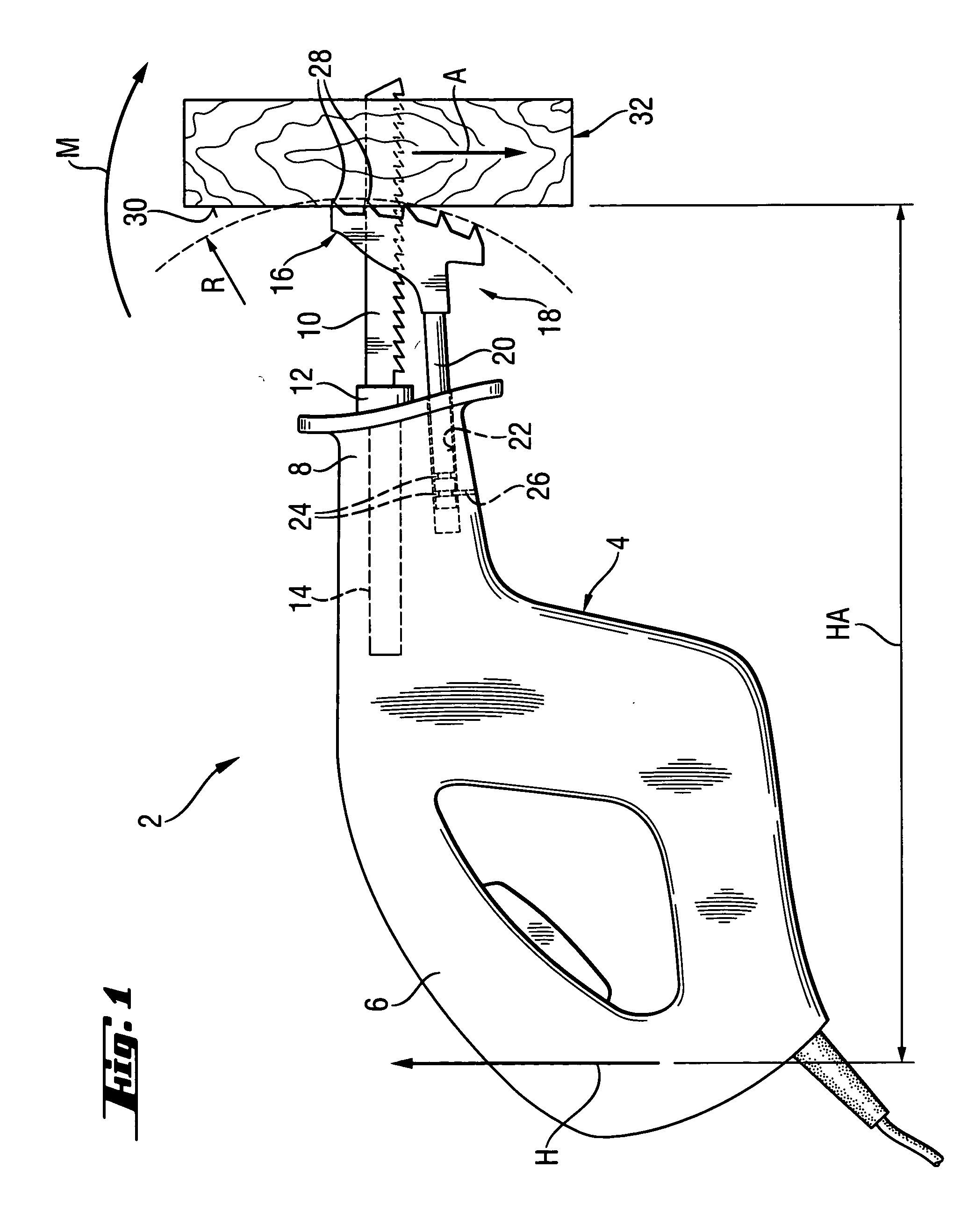

[0018]FIG. 1 shows a saber saw 2 with a housing 4. A main handle grip 6 is formed at a posterior end of housing 4. At a tool-end facing away form the posterior end, the housing 4 forms a device neck 8, which serves as an additional hand grip.

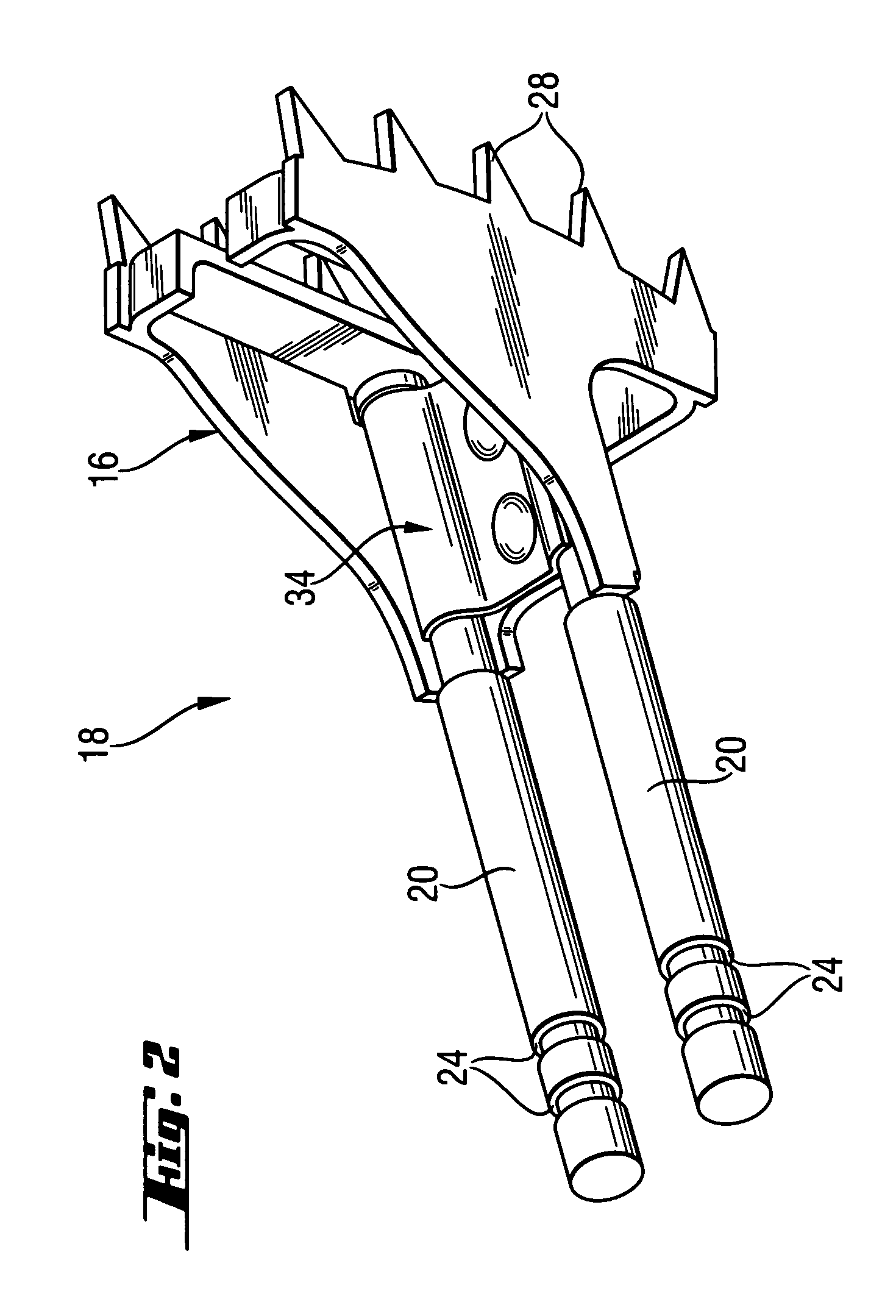

[0019] At a free end of the device neck 8, a saw blade 10 projects from the housing 4, which is fastened using a tool receptacle 12 on a tool spindle 14 of the saber saw 2. The saw blade 10 passes through a contacting element 16 of a guide adapter 18, which is represented in FIG. 2 separated from the saber saw.

[0020] The guide adapter 18 can be secured at the device neck 8 of the saber saw 2 using carrier means such as two rods 20 arranged parallel to each other and having a round cross-section. For securing, the rods 20 are inserted into hollow cylindrical receptacles 22 on the device neck 8. The hollow cylindrical receptacles 22 thus form a free cross-section, which corresponds to the cross-section of the rods 20.

[0021] For axial securing i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com