Method for regeneration of diesel soot filtering device

a diesel soot filtering and diesel technology, applied in the direction of machines/engines, exhaust treatment electric control, separation processes, etc., can solve the problems of general inability to apply the above condition to a specific, adversely affecting the quality of the vehicle, and carrying ou

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Reference will now be made in detail to the preferred embodiment of the present invention with reference to the attached drawings.

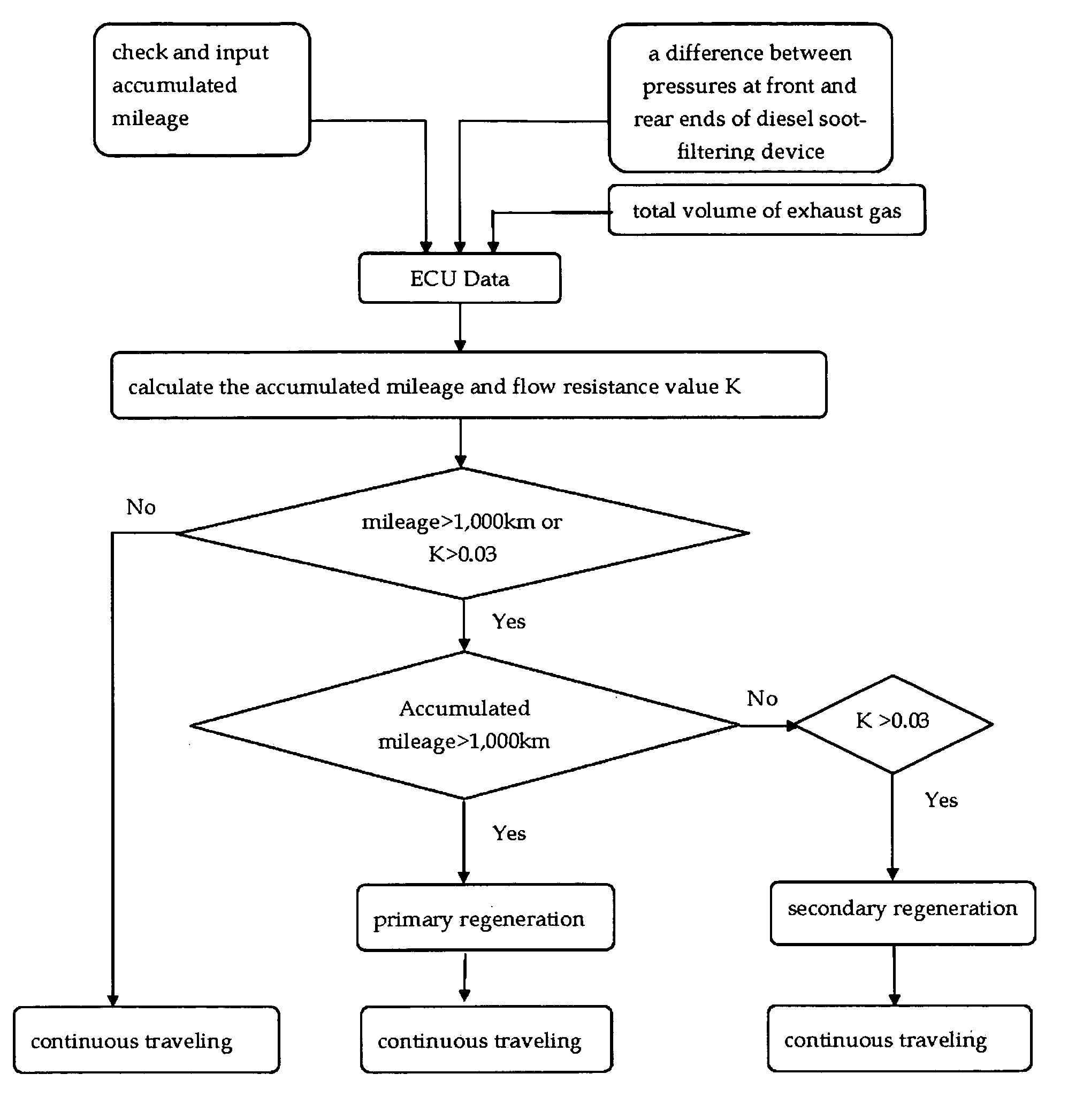

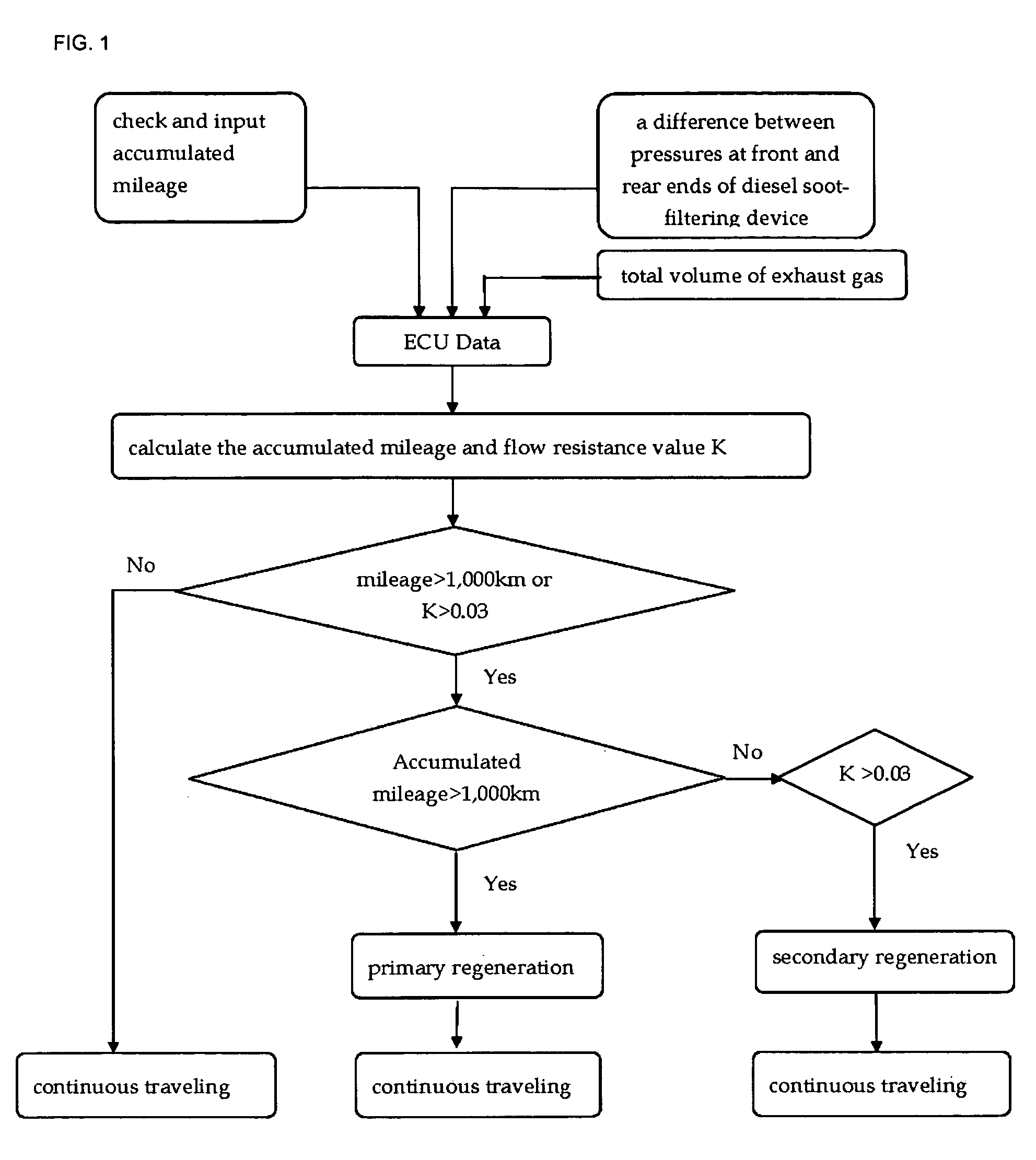

[0034] In view of the above-mentioned conditions, there is needed an improved method for determining the start and end points for the regeneration of a soot filtering device. Start and end points for regeneration may be determined by measuring a flow resistance value obtained by dividing a difference between pressures at front and rear ends of a diesel soot-filtering device by the flow rate of exhaust gas depending upon the amount of soot accumulated in a soot-filtering device regardless of the conditions of the engine and vehicle. This permits determination of a degree of accumulated soot and the measured corresponding flow resistance value, so that a software basis may be prepared. The start and end points of compulsory regeneration of the soot-filtering device can be easily determined through the later measurement of a flow resistance value in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com