Pole sander

a pole sander and sander technology, applied in the field of sanders, can solve the problems of affecting the function of the sander, several undesirable features of the sander, and the time-consuming and labor-intensive work of the sander, so as to reduce the time required for sandpaper sheet replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

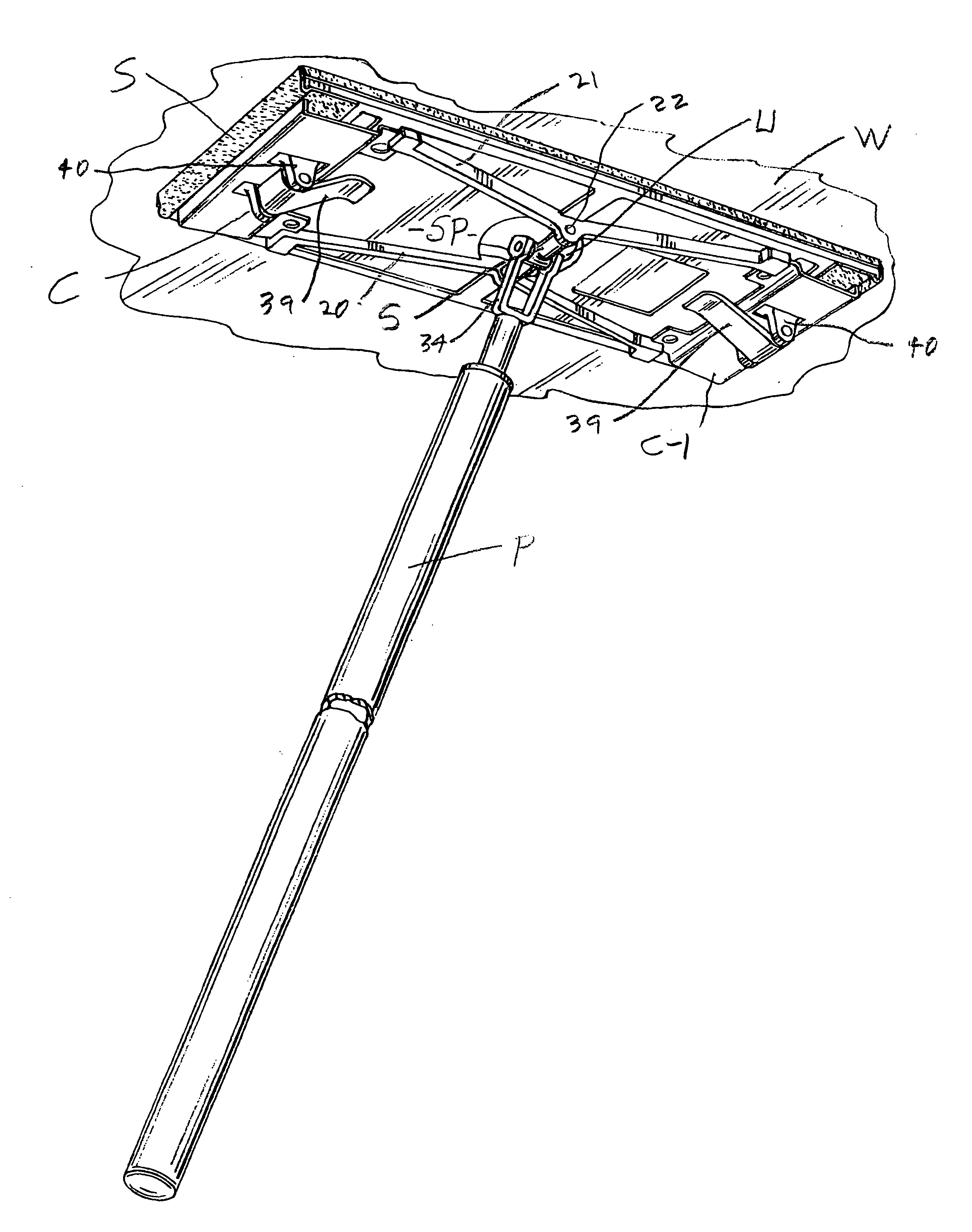

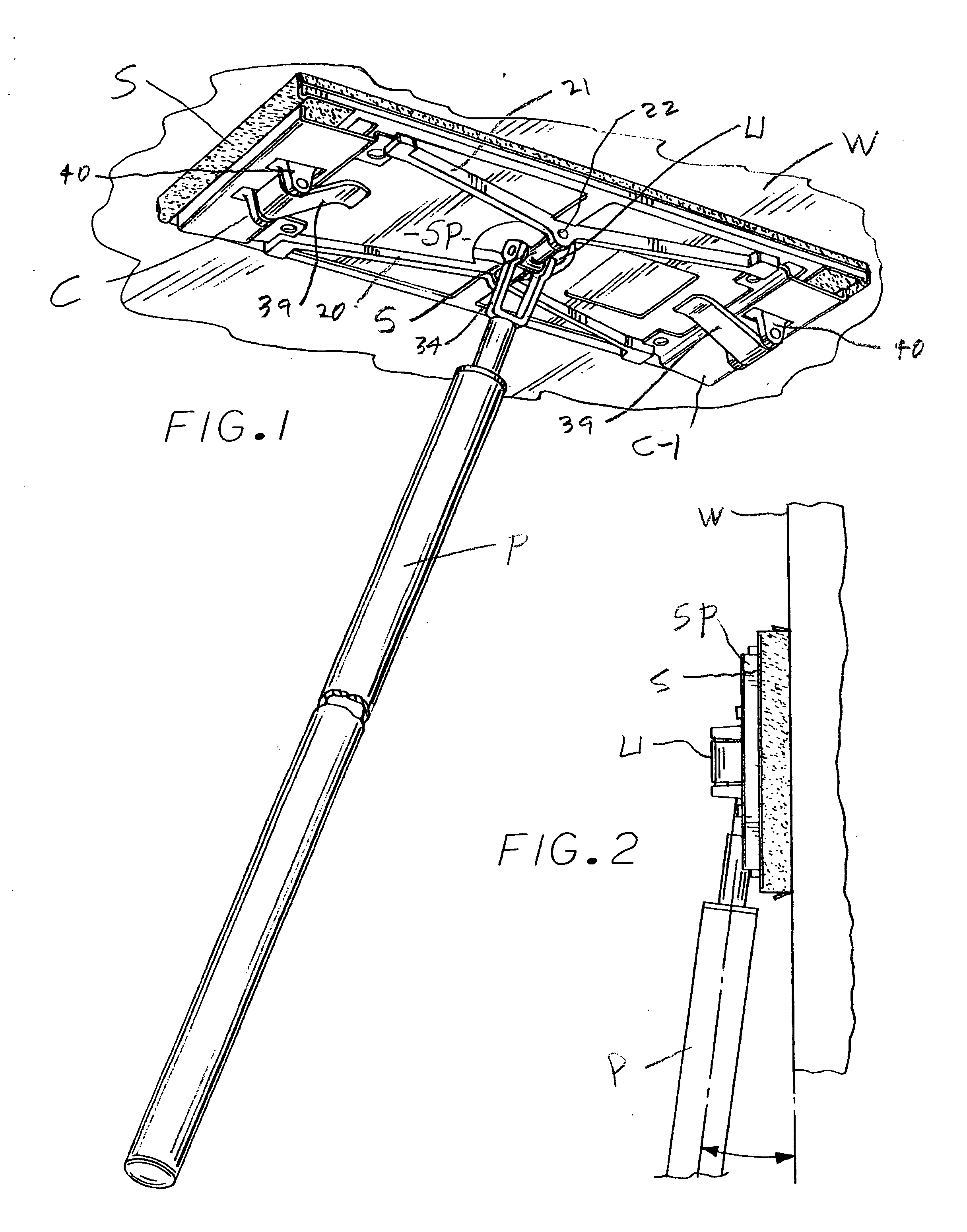

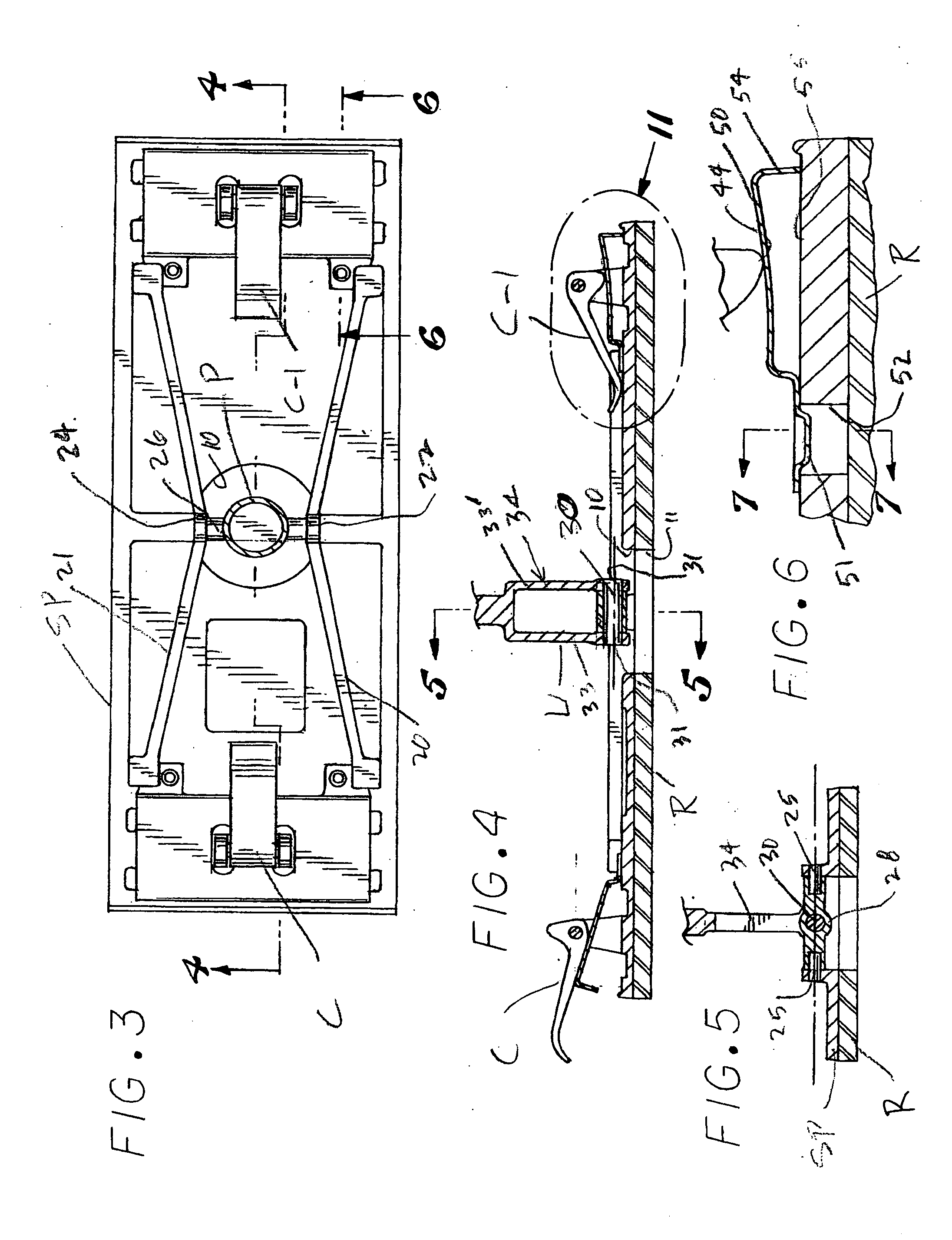

[0018] Referring to the drawings, a preferred embodiment of a pole sander embodying my present invention includes a rectangular sander plate SP which is connected to the upper end of a pole P by a universal joint assembly U. The opposite ends of the sander plate SP are provided with a pair of like, mirror-image clamp assemblies C and C-1 for releaseably securing one or more sheets of sandpaper S to the underside of a foam base pad R rigidly attached to the underside of sander plate SP, as by an adhesive (not shown). In the use of my pole sander the operator of the tool will manipulate the pole P so that the sandpaper S will slidingly and frictionally engage a desired area of a sheet of wallboard W or the like.

[0019] More particularly, the sander plate SP may be cast of a rigid material such as aluminum or plastic. An annular aperture 10 is cast into the plate coaxial with aperture 11 die cut in base pad R. The top of such sander plate is cast with a pair of integral longitudinally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com