Condom testing apparatus

a testing apparatus and chamber technology, applied in the direction of fluid tightness measurement, instruments, structural/machine measurement, etc., can solve problems such as deemed defective, and achieve the effect of increasing the testing rate and reducing the spacing of test mandrels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

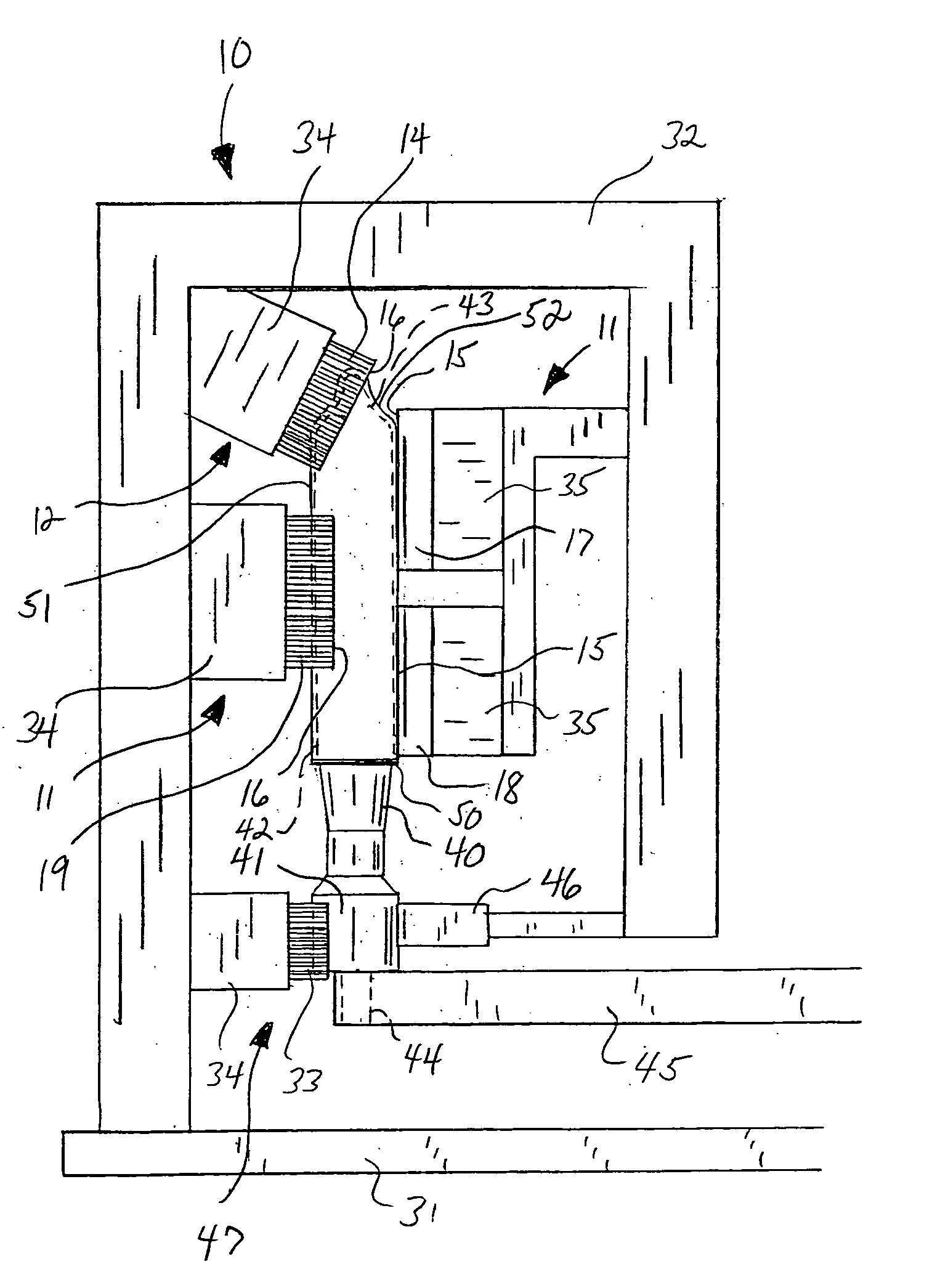

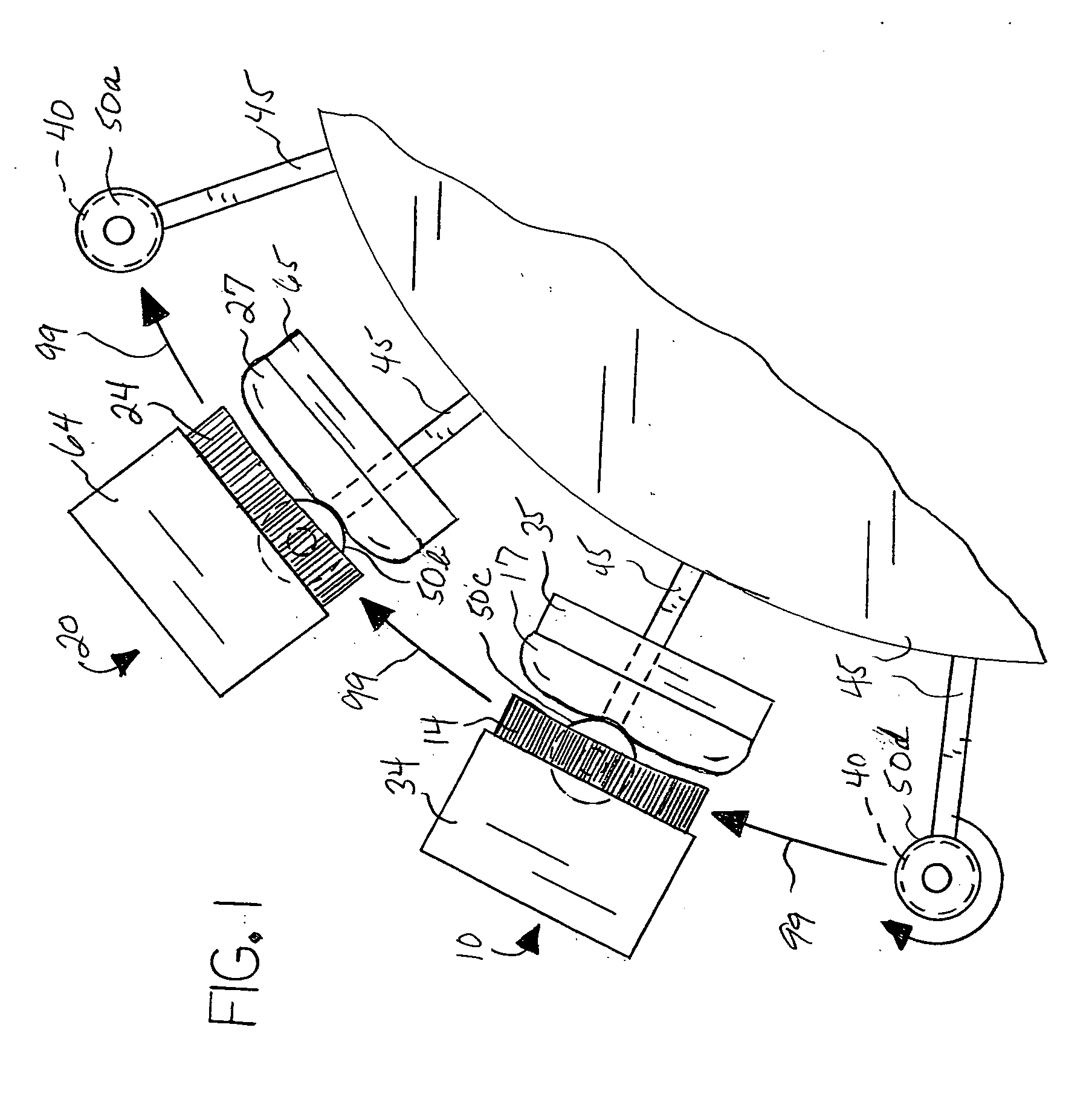

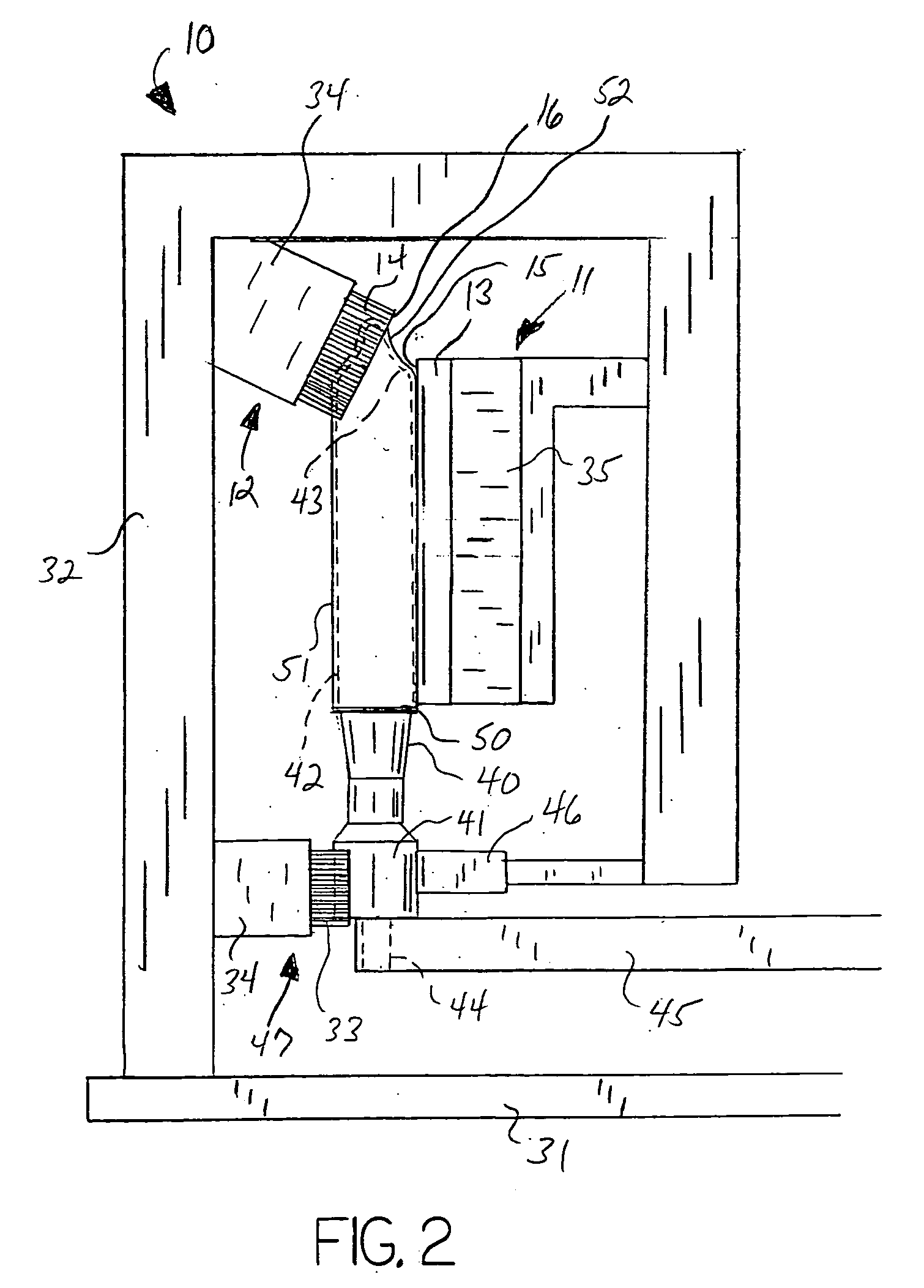

[0017] With reference to the drawings, the invention will now be described in detail with regard for the best mode and the preferred embodiment. For purposes of this disclosure, the invention will be arbitrarily described such that the central axes of the mandrels are oriented vertically with the nipple end of the mandrel and condom on top, and such that the mandrels are positioned on a platform that rotates or moves horizontally, such that any references to relative direction are based on this construct. Furthermore, in this disclosure the individual mandrels are described as rotating clockwise and the platform as rotating clockwise. It is understood, however, that the orientation and rotation directions of the condom defect testing apparatus may be varied without departing from the scope of the claimed invention.

[0018] In general, the invention is a condom defect testing apparatus for testing individual condoms 50 for defects, such as holes, tears or thin-walled regions susceptib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| circumference | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com