Active-matrix-driven display device

a display device and active matrix technology, applied in semiconductor devices, instruments, electrical apparatus, etc., can solve the problems of increased power consumption, increased power consumption, and the same problems are encountered in circuit configurations employing any other driving method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

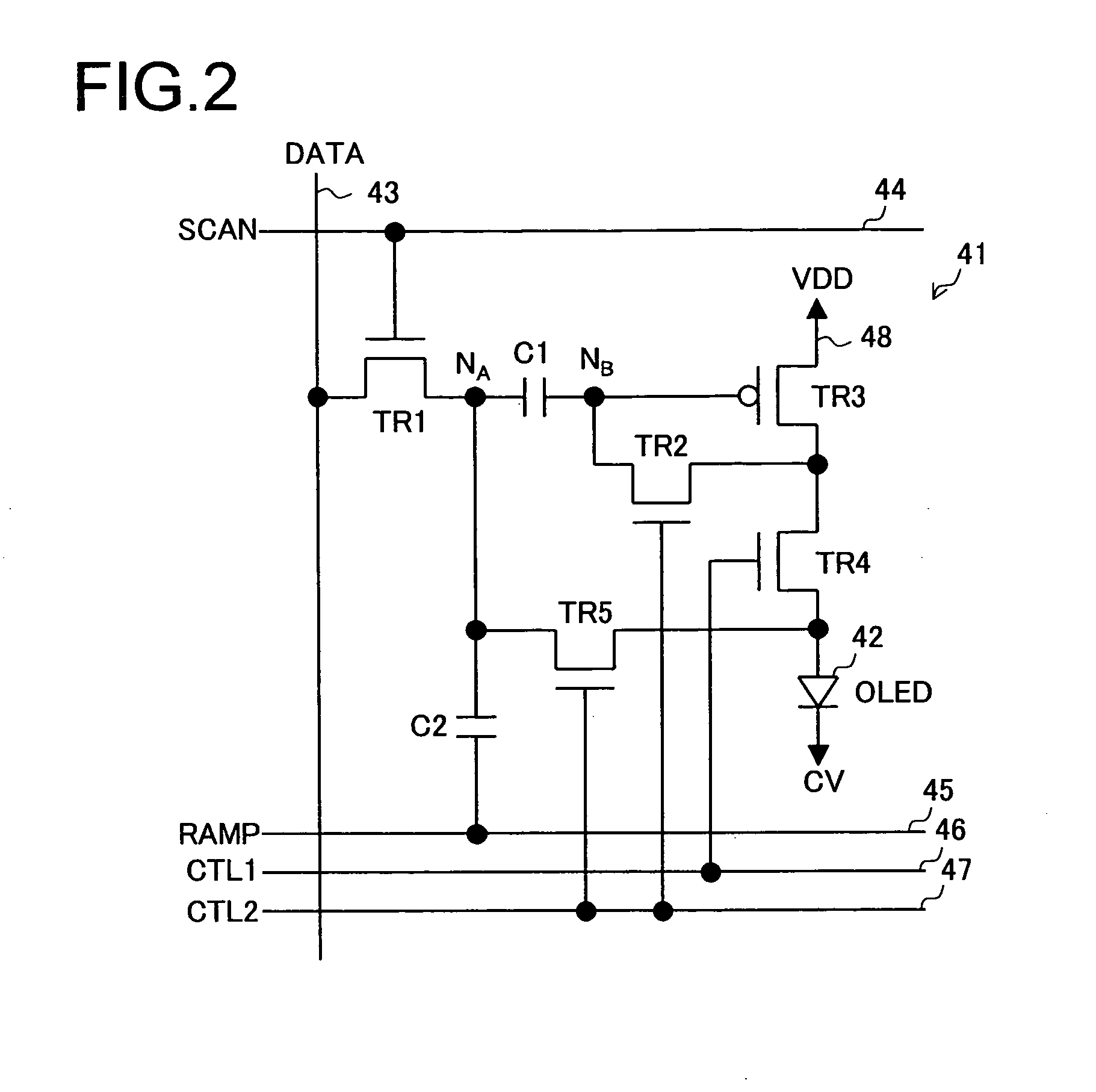

[0159] A first embodiment of the present invention as applied to an organic EL display device will be specifically described below with reference to the relevant drawings.

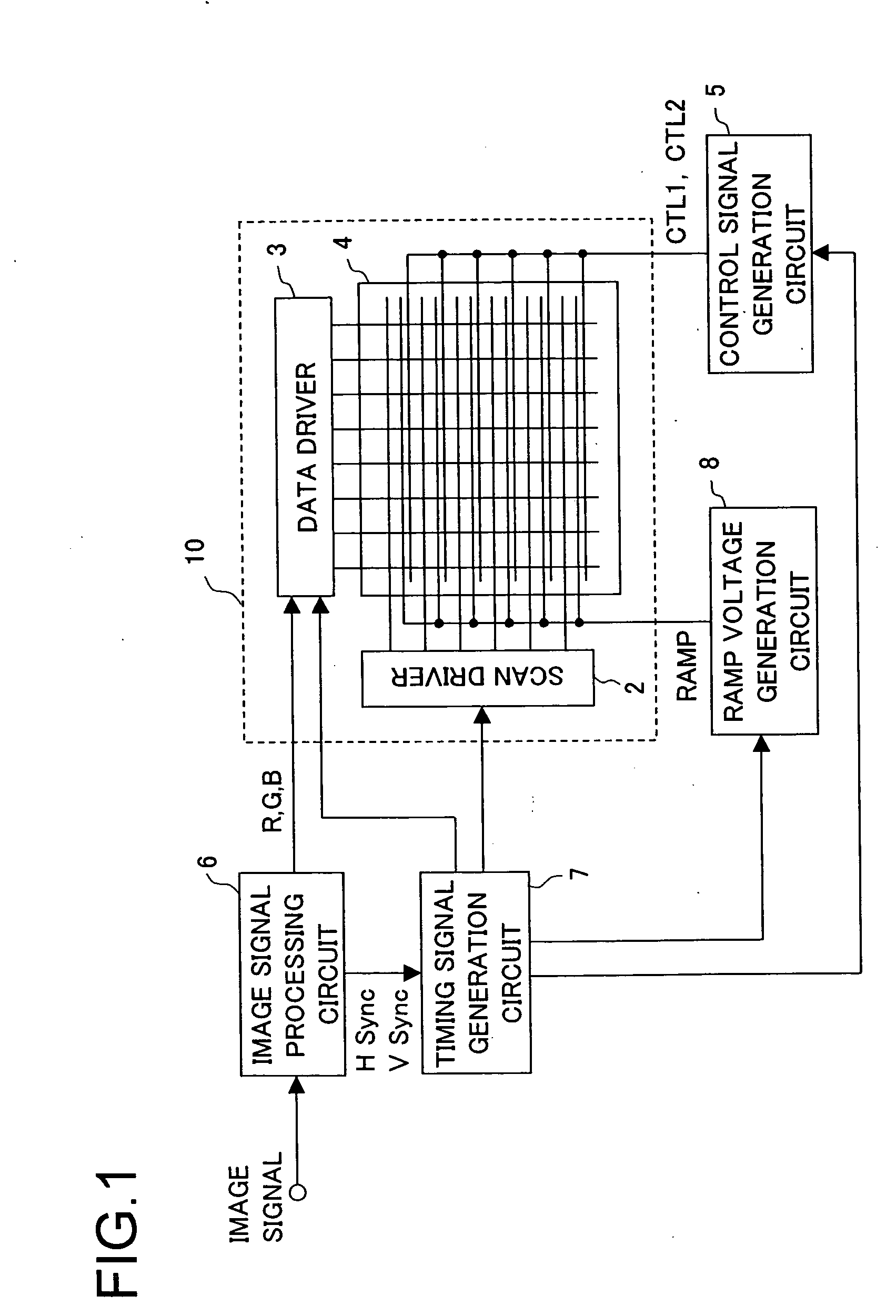

FIG. 1—Overall Configuration Block Diagram

[0160]FIG. 1 is a block diagram showing the overall configuration of the organic EL display device of a first embodiment of the present invention. As shown in FIG. 1, the organic EL display 10 has a display panel 4 composed of a plurality of pixels arrayed in a matrix, and this display panel 4 is connected to: a scan driver 2 that feeds a scan voltage to each pixel; a data driver 3 that feeds a data voltage to each pixel; a ramp voltage generation circuit 8; and a control signal generation circuit 5. The organic EL display device shown in FIG. 1 displays on the display panel 4 an image according to an image signal fed from an image source (external signal source) such as a television receiver (unillustrated).

[0161] The image signal fed from an image source such as a tele...

second embodiment

[0195] A second embodiment of the present invention as applied to an organic EL display device will be described below. The overall configuration of the organic EL display device of the second embodiment of the present invention is substantially the same as that shown in FIG. 1; therefore, no separate diagram is furnished in that aspect, and the following description places emphasis on differences from the first embodiment.

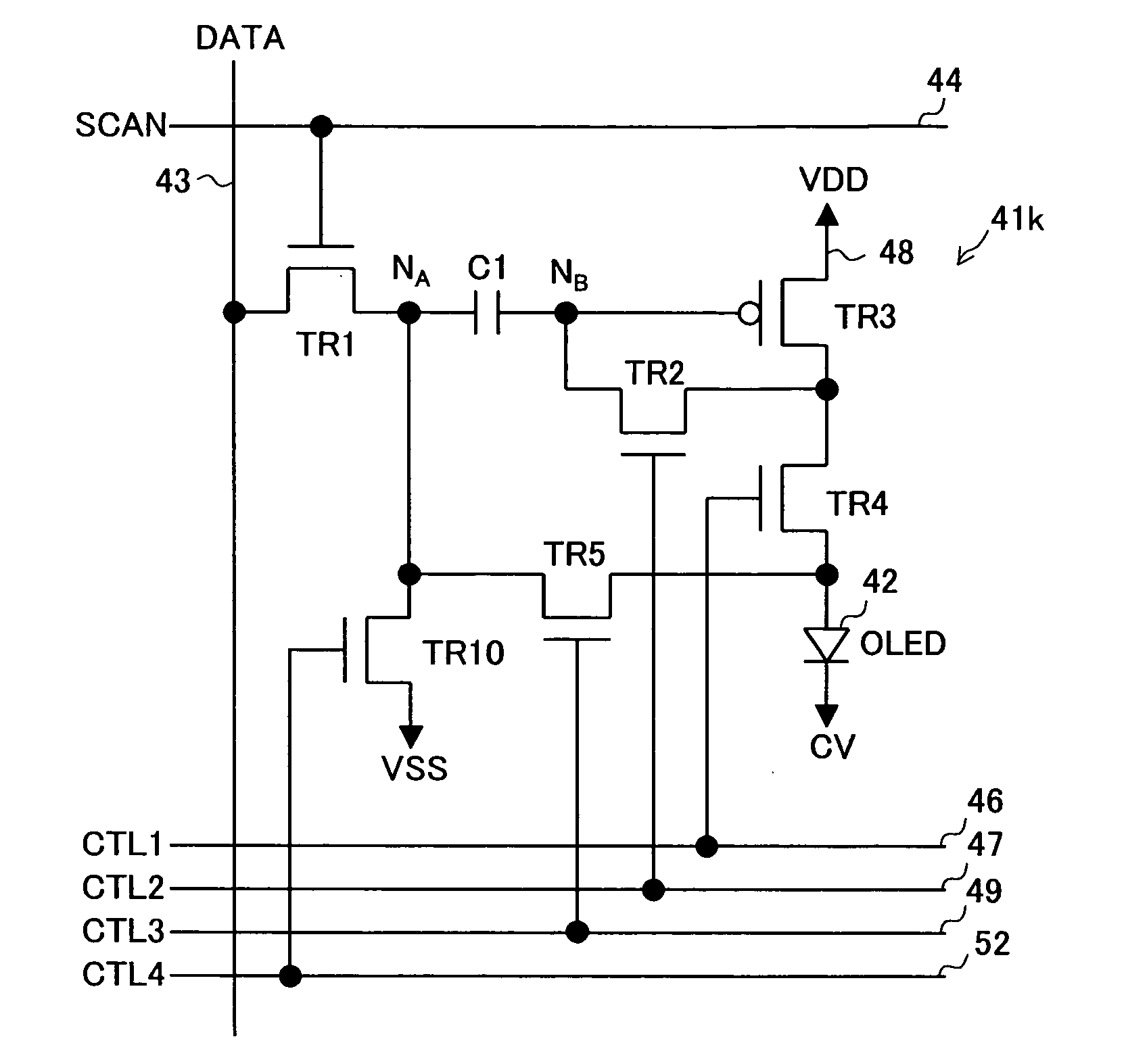

[0196] The display panel 4 is so modified that each pixel 41a constituting it is configured as shown in FIG. 5. In FIG. 5, such elements as are found also in FIG. 2 are identified with common reference numerals and symbols, and no overlapping explanations will be repeated. The pixel 41a (the pixel circuit of the pixel 41a) differs from the pixel 41 (the pixel circuit of the pixel 41) shown in FIG. 2 in the following respects: a resetting transistor TR6 is additionally provided of which the first electrode (for example, drain) and the second electrode (for example...

third embodiment

[0204] A third embodiment of the present invention as applied to an organic EL display device will be described below. The overall configuration of the organic EL display device of the third embodiment of the present invention is substantially the same as that shown in FIG. 1; therefore, no separate diagram is furnished in that aspect, and the following description places emphasis on differences from the first embodiment.

[0205] The display panel 4 is so modified that each pixel 41b constituting it is configured as shown in FIG. 7. In FIG. 7, such elements as are found also in FIG. 2 are identified with common reference numerals and symbols, and no overlapping explanations will be repeated. The pixel 41b (the pixel circuit of the pixel 41b) differs from the pixel 41 (the pixel circuit of the pixel 41) shown in FIG. 2 in the following respects: a PWM circuit (pulse width modulation circuit) 50 is provided between the second electrode of the writing transistor TR1 and the node NA; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com